Fixed type crude oil cabin washing machine

The utility model relates to a tank washing machine and a fixed technology, which is applied to the cleaning equipment of oil tank ships, motor vehicles, and ship tanks, etc., and can solve the problems of complex structure, affecting the tank washing process and cleaning effect, and uneven vertical rotation speed of nozzles, etc. To achieve the effect of expanding the function and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

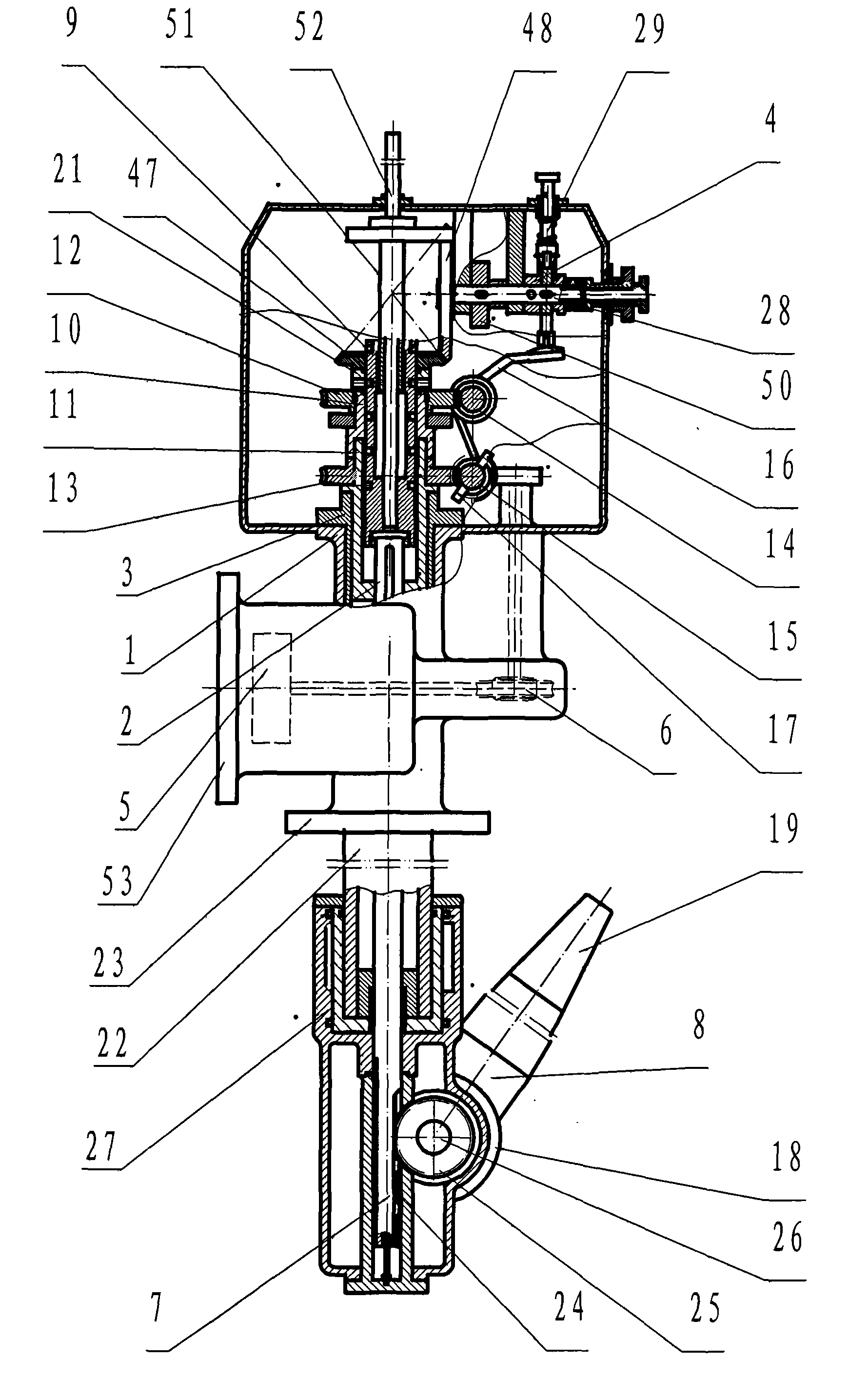

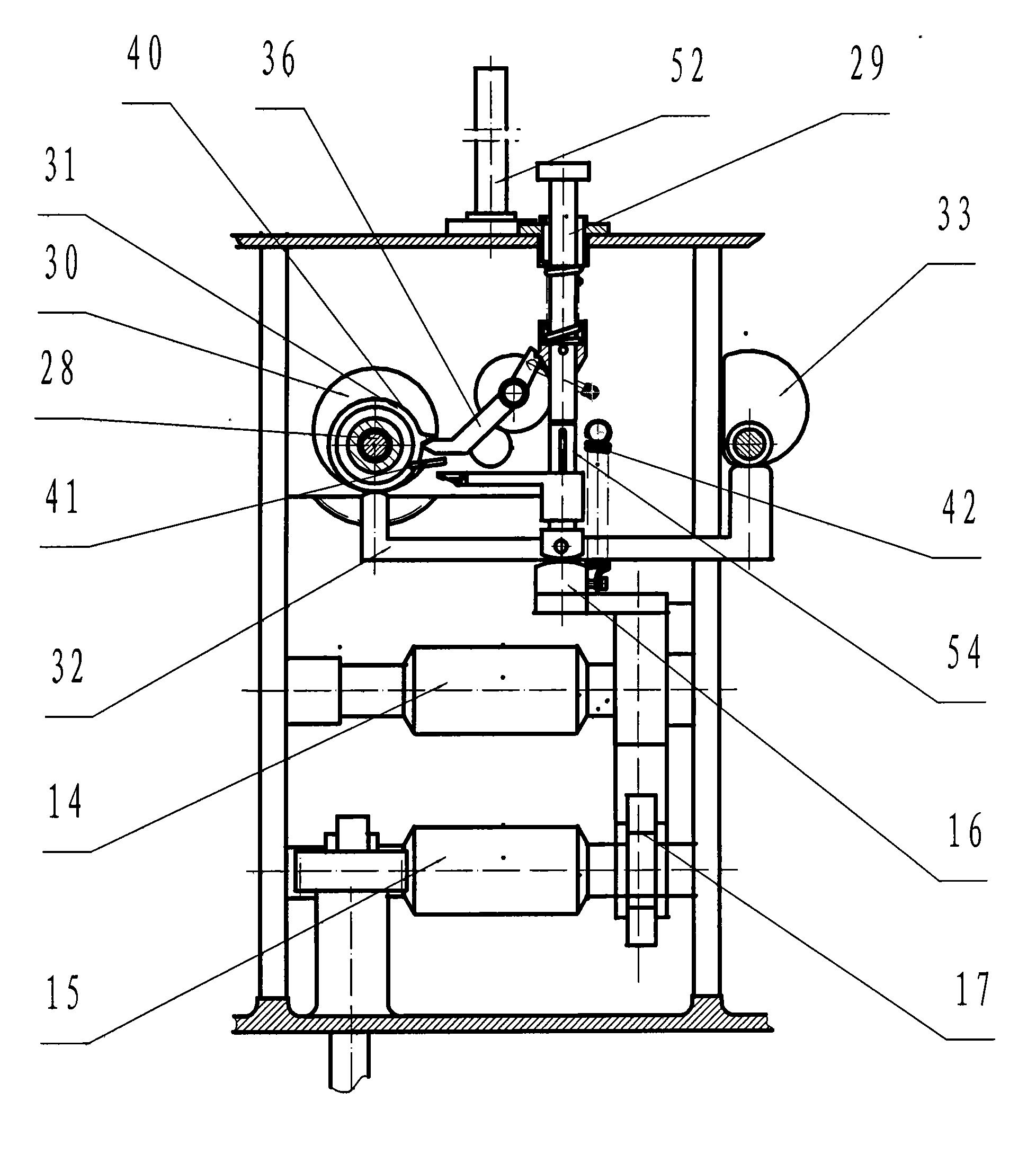

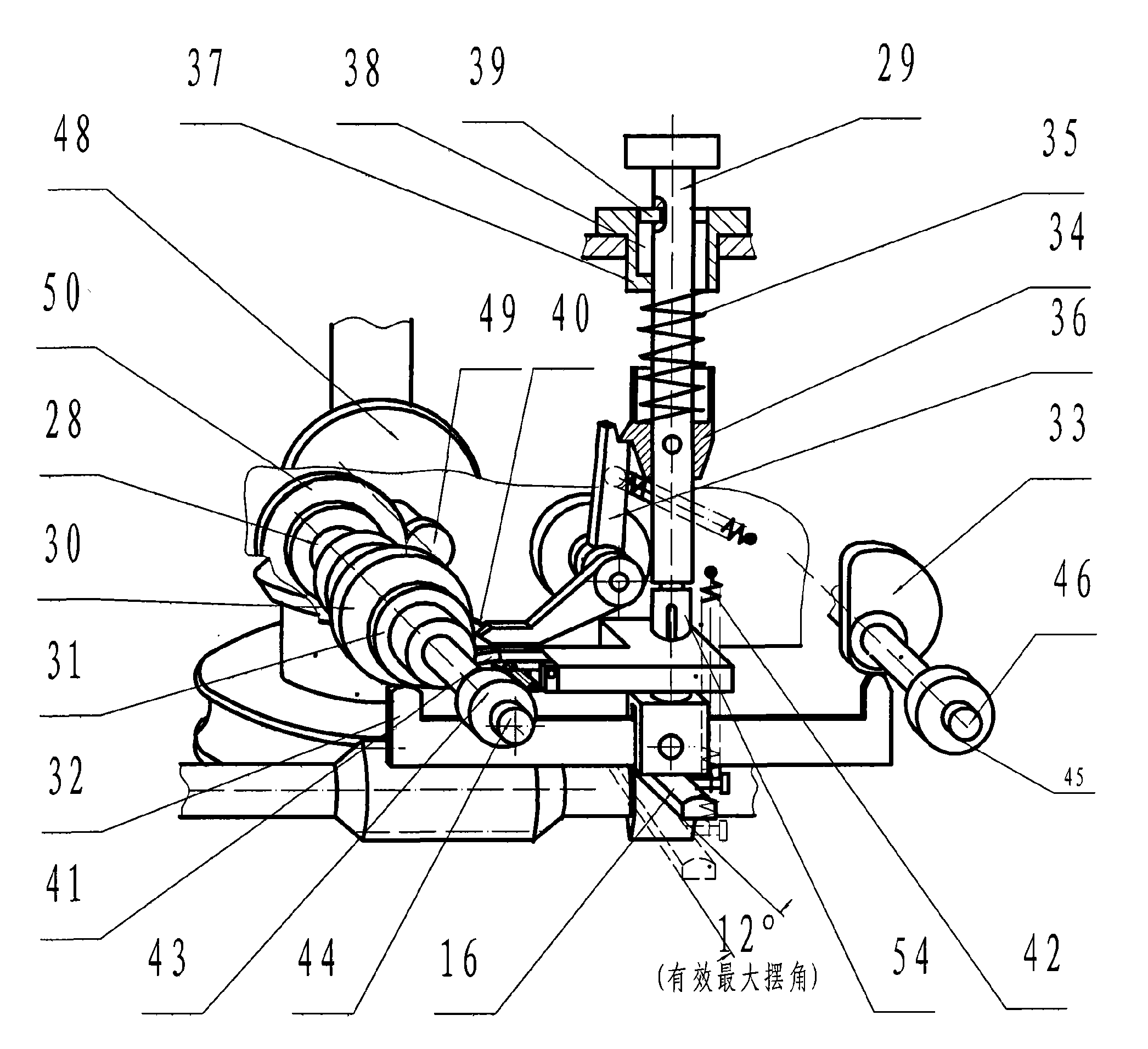

[0014] A fixed crude oil washing machine, comprising a main body 1, a main shaft 2 provided in the main body 1, a main transmission part 3 of the main shaft 2, a control mechanism 4 of the main shaft 2, an impeller 5, an impeller transmission part 6, and a main shaft through a transmission device 7 2 connected nozzles 8, the control mechanism 4 includes a control shaft 28, a speed regulating lever 32, a nozzle stop control lever 29, an automatic speed regulating cam 30 and a stall cam 31 are housed on the control shaft 28, and one end of the speed regulating lever 32 is connected to the automatic speed regulating lever 32. The speed regulating cam 30 contacts, and the other end contacts with the manual speed regulating cam 33. A support shaft 54 that can move up and down is provided in the middle of the speed regulating lever 32. The upper end of the support shaft 54 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com