Safe ventilated electric connector

An electrical connector and ventilated technology, applied in the field of ventilated electrical connectors, can solve problems such as top opening, seal failure, fixed connection damage, etc., and achieve the effects of easy use, guaranteed mating in place, and small vibration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

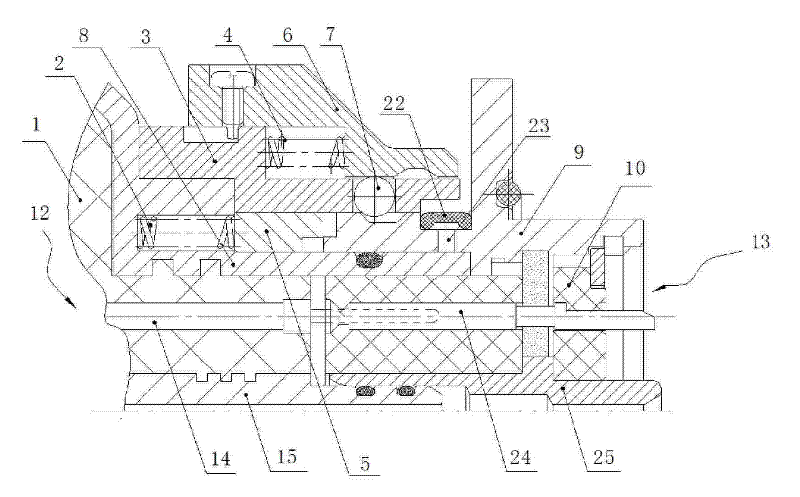

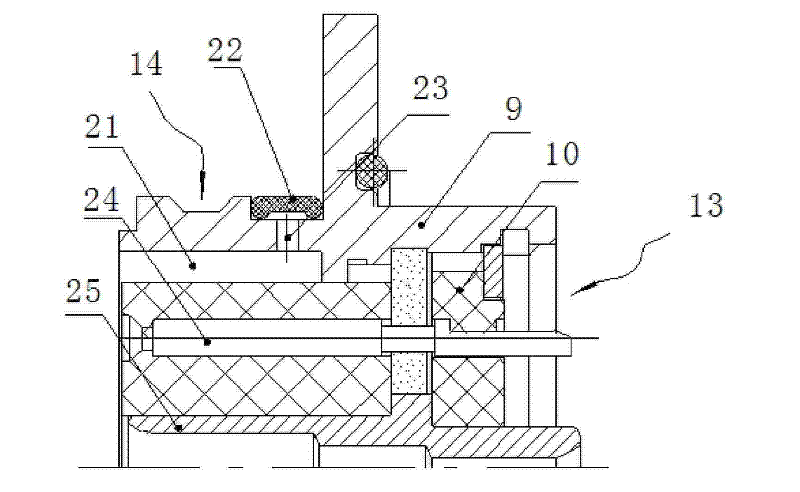

[0019] Embodiment one: if figure 1 , figure 2 , Figure 4 As shown, the safety ventilated electrical connector of the present invention includes a plug 12 and a socket 13 , and the insertion end of the plug 12 is provided with an opening for inserting the insertion end of the socket 13 . The plug 12 includes a plug housing 3, the plug-in end opening of the plug 12 is arranged at one end of the plug housing 3, the spline housing 8 is fixed in the plug housing 3, and the inner wall of the spline housing 8 is provided with a The extended spline, the spline housing 8 is fixed with a plug insulator 1, and a contact is inserted in the plug insulator 1, and the contact includes a high-pressure gas needle contact 15 located in the center of the connector and a high-voltage gas needle contact 15 located at the center of the connector. 14 around the electrical pin contacts. The socket 13 includes a socket housing 9 and a socket insulator 10 fixed therein. The socket housing 9 is pro...

Embodiment 2

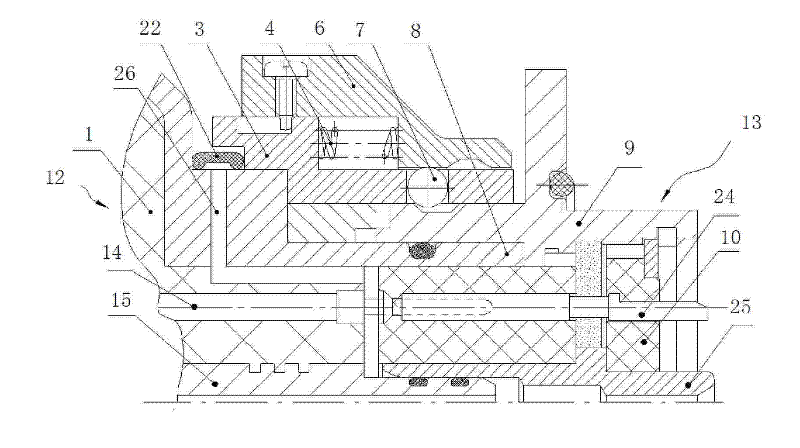

[0023] Embodiment two: if image 3 , Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the plug 12 is provided with more than one connecting mating surface of the insulator and the channel 26 on the outer wall of the plug 12 to form a pressure relief channel. The front section of the pressure relief channel It is set axially between the spline housing 8 and the insulator 1 , its rear end is radially set on the spline housing 8 , and the annular rubber pad 22 is packaged on the outer opening of the channel 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com