Tin-lead recovery method in waste circuit board

A waste circuit board, recycling method technology, applied in the field of heavy metal recycling by chemical method, can solve the problems of restriction, waste of tin and lead resources, etc., and achieve the effect of preventing pollution, improving environmental quality, high economic benefit and environmental significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

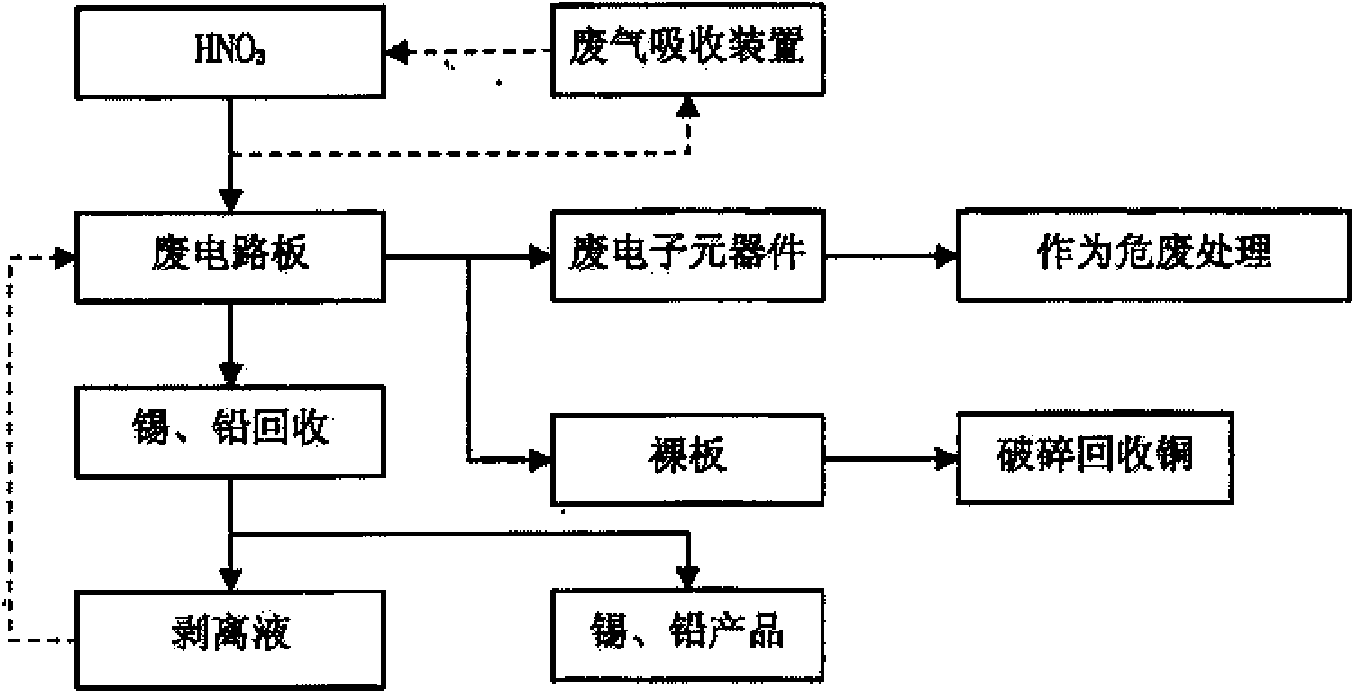

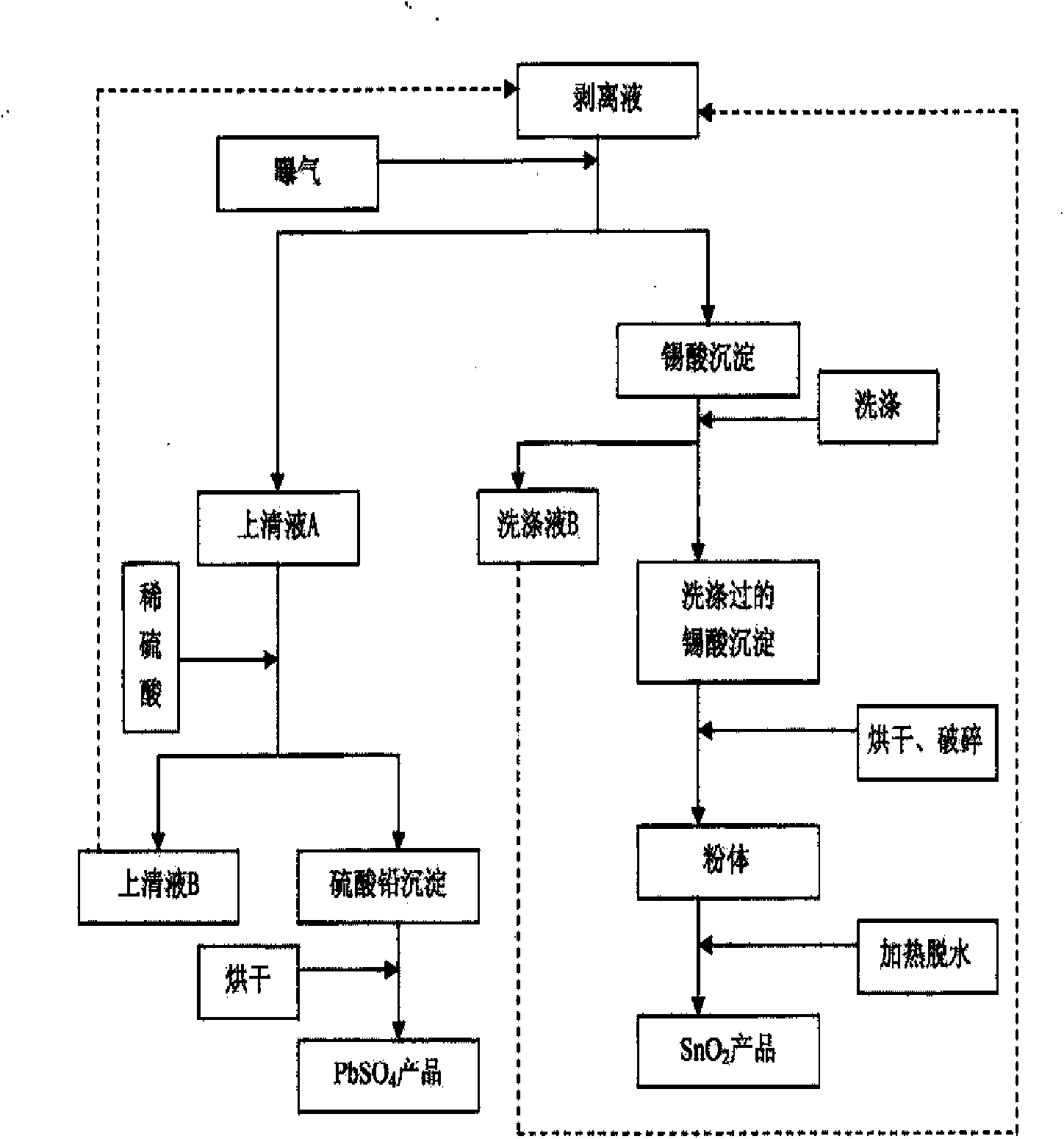

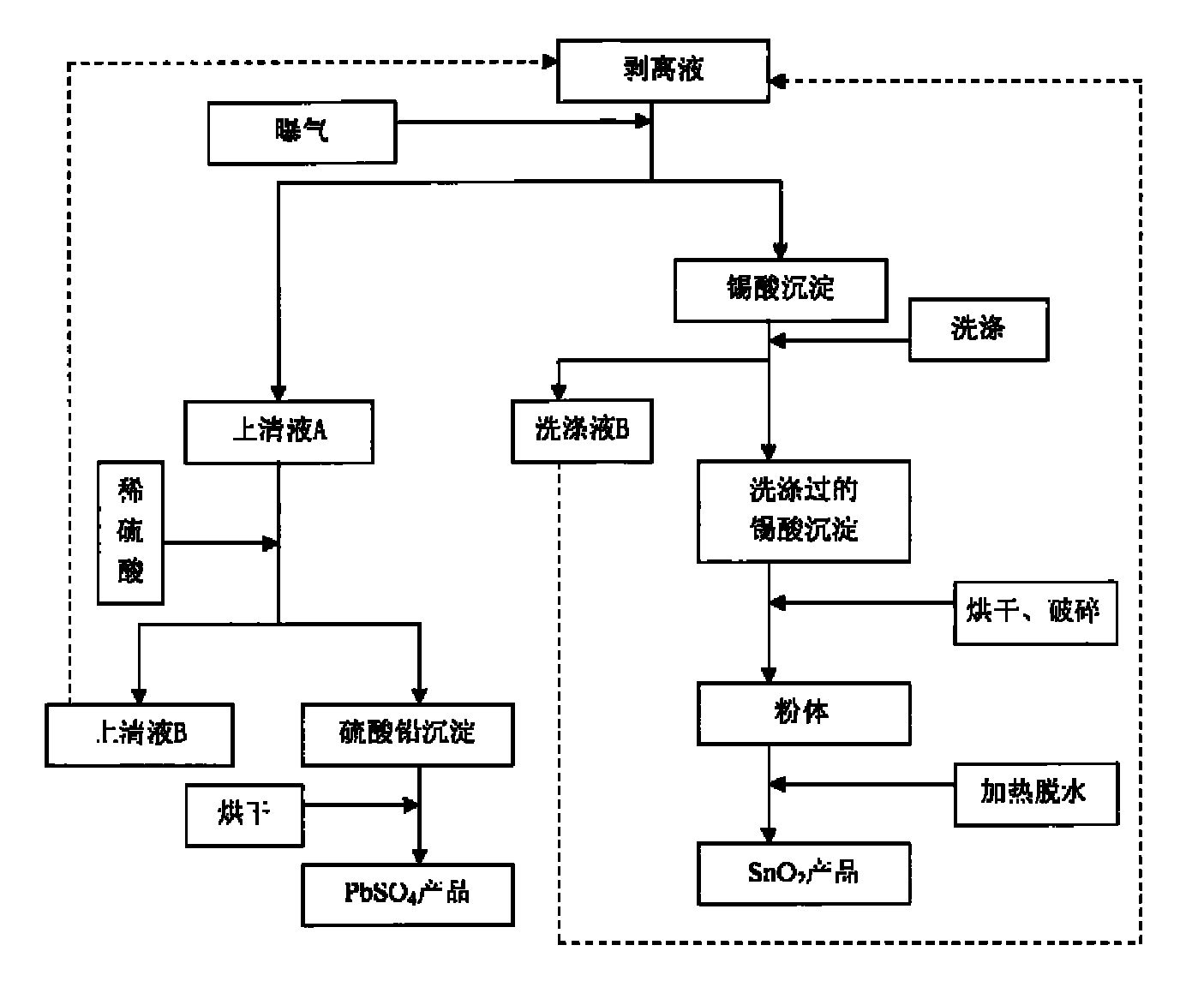

[0026] A method for recovering tin and lead in waste circuit boards, the method is to first wet strip the electronic components on the waste circuit boards, then carry out the classification precipitation and recovery of tin and lead in the waste circuit boards, and reclaim the The waste gas and waste liquid generated in the process are reused in the recovery process;

[0027] The method sequentially includes the following steps:

[0028] I. Dismantling of electronic components:

[0029] A. Use HNO to waste circuit boards 3 Carry out soaking treatment; Described soaking treatment time is 6 hours, and described HNO 3 The concentration of the waste circuit board is 1mol / L; after the electronic components of the waste circuit board fall off, the bare board, the waste electronic components, and the primary stripping liquid are obtained; the primary stripping liquid is filtered to obtain the stripping liquid; the Filtration treatment adopts filter cloth;

[0030] B. Wash the ba...

Embodiment 2

[0045] The steps of the method for recycling tin and lead in waste circuit boards described in this embodiment are the same as those in Embodiment 1, the difference being:

[0046] I. Dismantling of electronic components:

[0047] A. Use HNO to waste circuit boards 3Carry out soaking treatment; Described soaking treatment time is 4 hours, and described HNO 3 The concentration is 2mol / L;

[0048] After testing, the SnO 2 The product has a purity of 99%, the PbSO 4 The purity of the product reaches 99%; the recovery rate of tin and lead in the waste circuit board reaches 99%; the detection method is the same as in Example 1.

Embodiment 3

[0050] The steps of the method for recycling tin and lead in waste circuit boards described in this embodiment are the same as those in Embodiment 1, the difference being:

[0051] I. Dismantling of electronic components:

[0052] A. Use HNO to waste circuit boards 3 Carry out soaking treatment; Described soaking treatment time is 1 hour, and described HNO 3 The concentration is 3mol / L;

[0053] After testing, the SnO 2 The product has a purity of 90%, the PbSO 4 The purity of the product reaches 90%; the recovery rate of tin and lead in the waste circuit board reaches 98%; the detection method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com