Test method for dynamic working conditions of vehicle electric drive system

A technology of electric drive system and test method, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc. It can solve the problem of ignoring the working state of the battery pack, the source of energy feedback, driving resistance energy consumption, and testing the characteristics of the whole vehicle Lack of other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the embodiments.

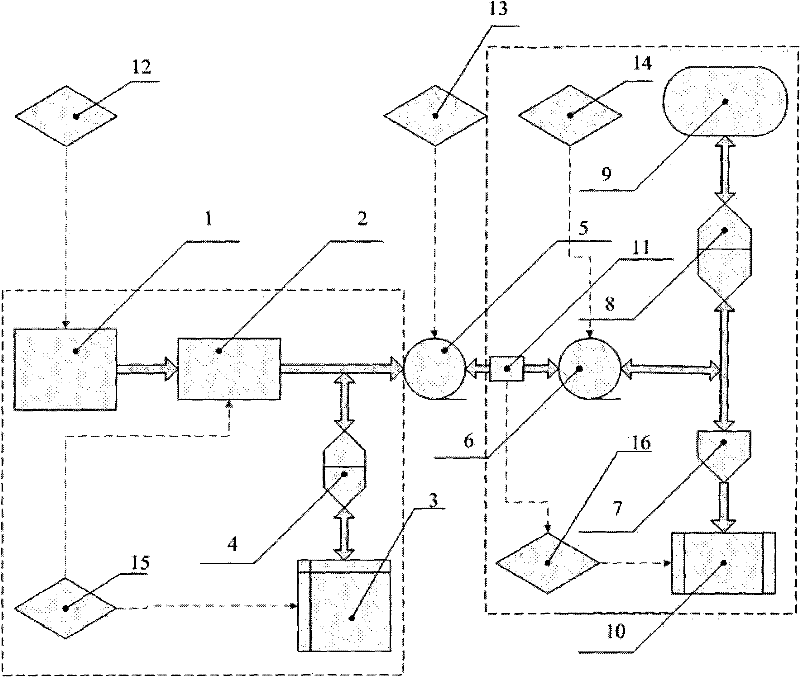

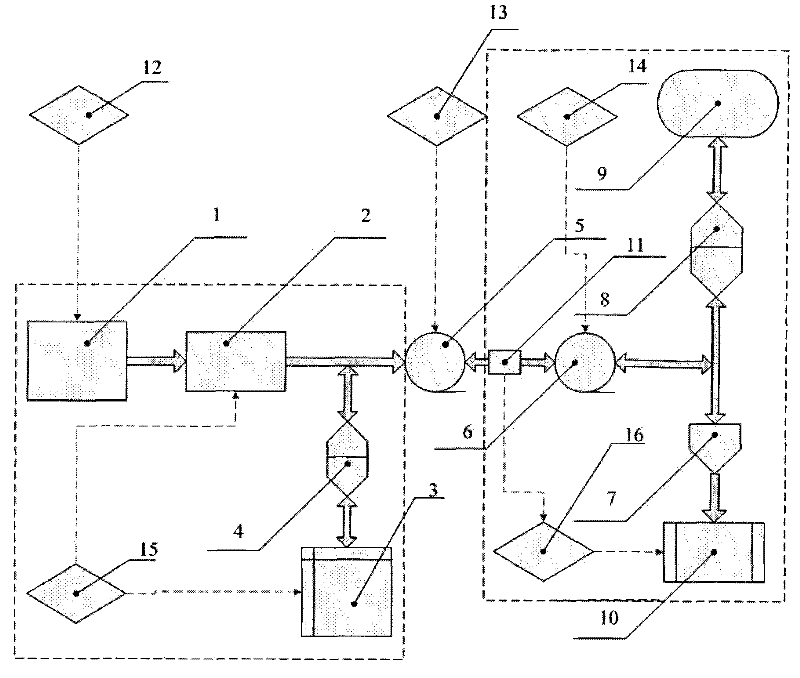

[0014] refer to figure 1 , when the vehicle is in the driving state, the fuel cell simulator 1 and the battery pack 3 jointly provide electric energy to the on-board motor 5 under the coordinated control of the power regulation controller 15, and the on-board motor 5 converts the electric energy under the control of the on-board motor controller 13 In order to transfer the mechanical energy to the load motor 6, the load motor controller 14 obtains the power demand by calculating the current vehicle speed and acceleration, etc., thereby controlling the load motor 6 to convert the mechanical energy into electric energy, while the load simulation controller 16 calculates the driving resistance (including rolling resistance, Air resistance, etc.) account for the proportion of the total power, and control the power consumed by the resistance box 10. At this time, the electric energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com