Method for preventing broken pieces of band tail from blocking shearing when shearing band tail of cold rolled strip steel production unit

A technology of cold-rolling strip steel and chips, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems affecting the production continuity of the unit and reducing the production efficiency of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

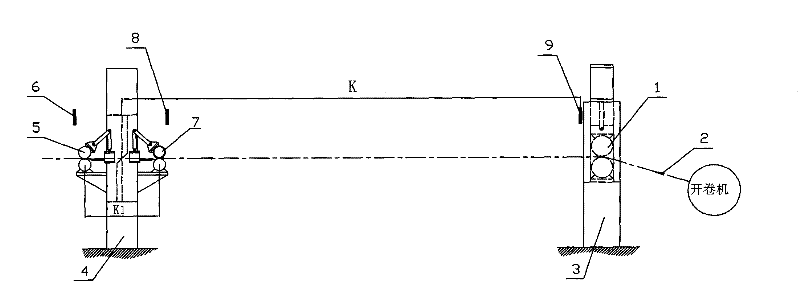

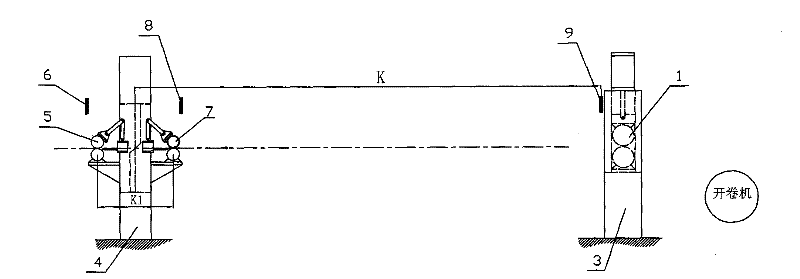

[0058] first as image 3 As shown in the figure, the tape tail escapes from the coiler after the tailing of the unit is completed, and when the tape tail passes the entrance and turns to the photoelectric cell 9 at the exit of the pinch roller, the passage of the tape tail is calculated by the rotary encoder installed on the 7-axis of the entrance shear and entrance pinch roller The entrance turns to the distance of the photocell 9 at the exit of the pinch roller, and the distance between the entrance and the photocell 9 at the exit of the pinch roller and the entrance shear is known as K, so that the remaining tail length L1=1.5m that needs to be cut can be calculated; At this time, the total length L1 of the remaining tape tail that needs to be cut is directly below the entrance shear, and the first knife cut is performed to complete the separation of the qualified and unqualified parts of the tape tail; the unqualified part is the remaining waste to be cut. At this time, Th...

Embodiment 2

[0062] first as image 3 As shown in the figure, the tape tail escapes from the coiler after the tailing of the unit is completed, and when the tape tail passes the entrance and turns to the photoelectric cell 9 at the exit of the pinch roller, the passage of the tape tail is calculated by the rotary encoder installed on the 7-axis of the entrance shear and entrance pinch roller The entrance turns to the distance of the photocell 9 at the exit of the pinch roller, and the distance between the entrance and the photocell 9 at the exit of the pinch roller and the entrance shear is known as K, so that the remaining tail length L1=5.3m that needs to be cut can be calculated; At this time, the total length L1 of the remaining tape tail that needs to be cut is directly below the entrance shear, and the first knife cut is performed to complete the separation of the qualified and unqualified parts of the tape tail; the unqualified part is the remaining waste to be cut. At this time, Th...

Embodiment 3

[0070] first as image 3 As shown in the figure, the tape tail escapes from the coiler after the tailing of the unit is completed, and when the tape tail passes the entrance and turns to the photoelectric cell 9 at the exit of the pinch roller, the passage of the tape tail is calculated by the rotary encoder installed on the 7-axis of the entrance shear and entrance pinch roller The entrance turns to the distance of the photocell 9 at the exit of the pinch roller, and the distance between the entrance and the photocell 9 at the exit of the pinch roller and the entrance shear is known as K, so the total length L1 of the remaining tail that needs to be cut can be calculated = 3.99m; At this time, the total length L1 of the remaining tape tail that needs to be cut is directly below the entrance shear, and the first knife cut is performed to complete the separation of the qualified and unqualified parts of the tape tail; the unqualified part is the remaining waste to be cut. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com