Electric liftable automotive chassis

A vehicle frame and electric technology, applied in the field of electric lift frame, can solve the problems of inconvenient use, inconvenient disassembly, inconvenient disassembly and assembly, etc., and achieves the effects of simple operation, convenient operation and practicality, and convenience and practicality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

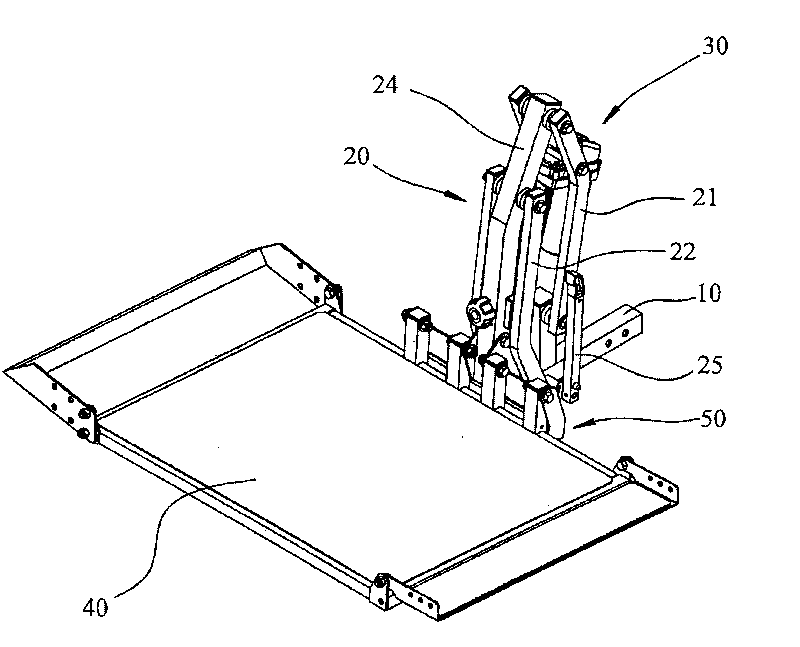

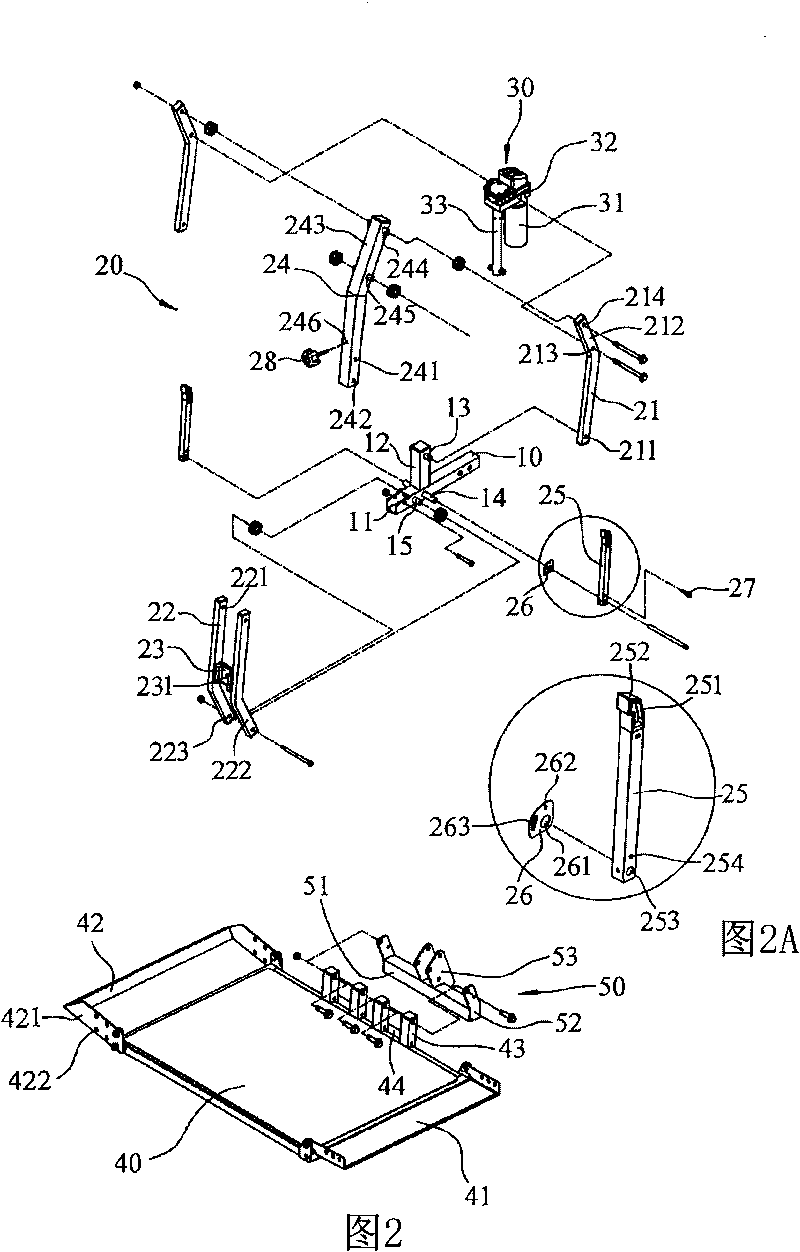

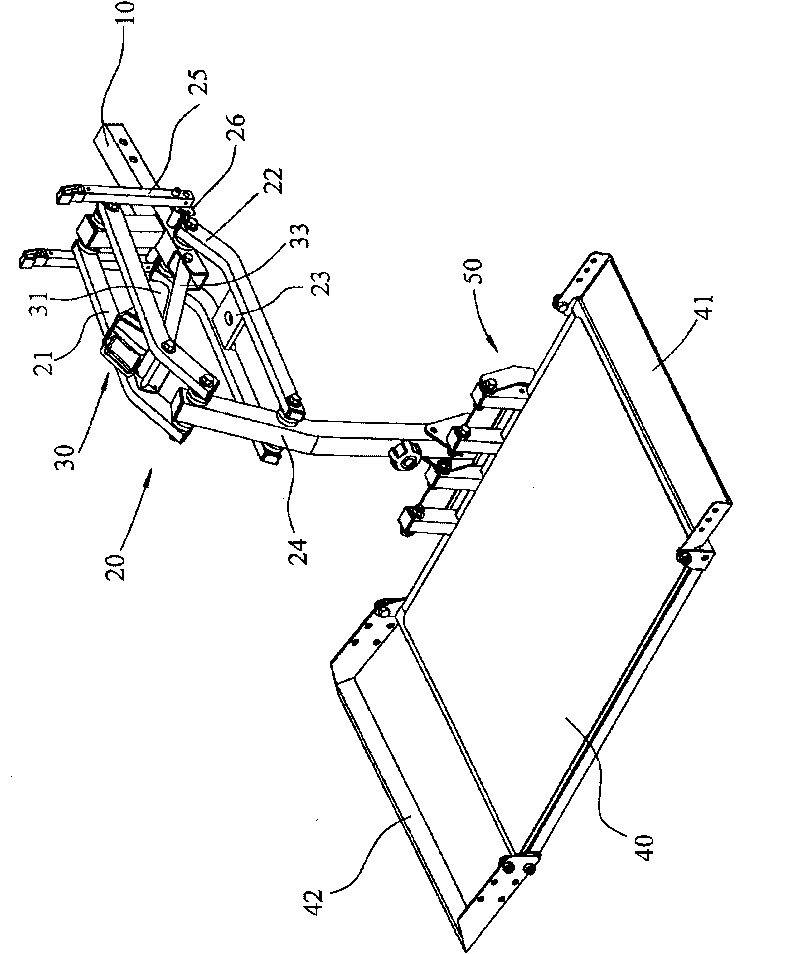

[0032] see Figure 1 ~ Figure 2 The diagram of a preferred embodiment of the present invention shown is a kind of electric lifting vehicle frame of the present invention, and its composition comprises:

[0033] Described fixed rod frame 10, its one end group is arranged on the rear end of the car, is provided with a sectional groove 11 at its other end, and described fixed rod frame 10 is provided with a connecting rod 12, on both sides of described connecting rod 12 A first shaft column 13 with an inner hole is provided respectively, and a second shaft column 14 and a third shaft column 15 with an inner hole are respectively provided on both sides of the fixed rod frame 10;

[0034] The connecting rod group 20 is composed of a plurality of connecting rods pivoted to each other. One end of the first connecting rod 21 is pierced with a first shaft hole 211, and the other end of the first connecting rod 21 is provided with a suitable The connecting end 212 of the slope, a secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap