Frame carrying structure

A vehicle-carrying frame and pivot joint technology, which is applied in the fields of car-carrying frame structure and anti-shake structure, can solve the problems of not smooth cooperation between the latch lever and the seat body, inability to fold conveniently, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

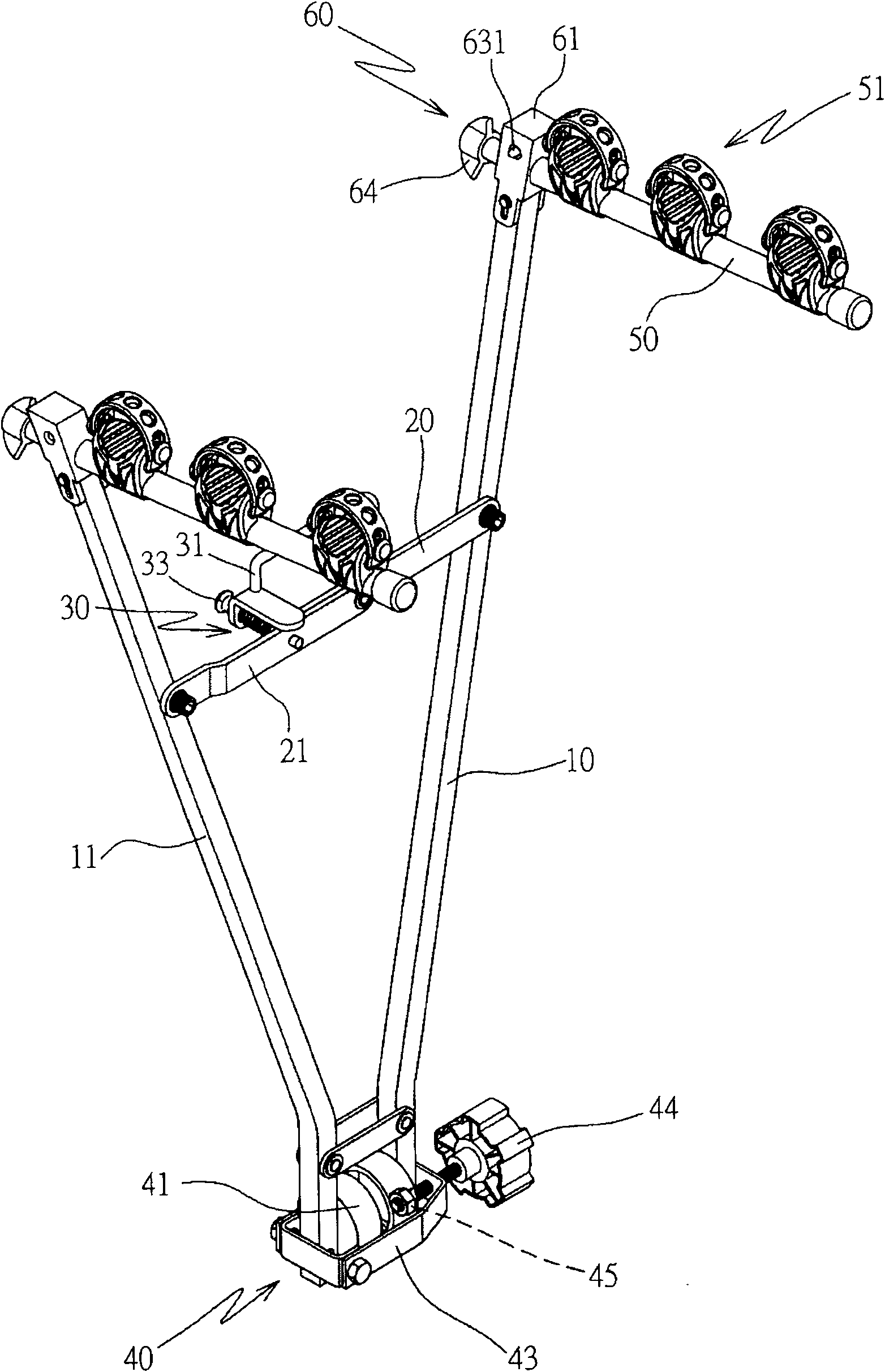

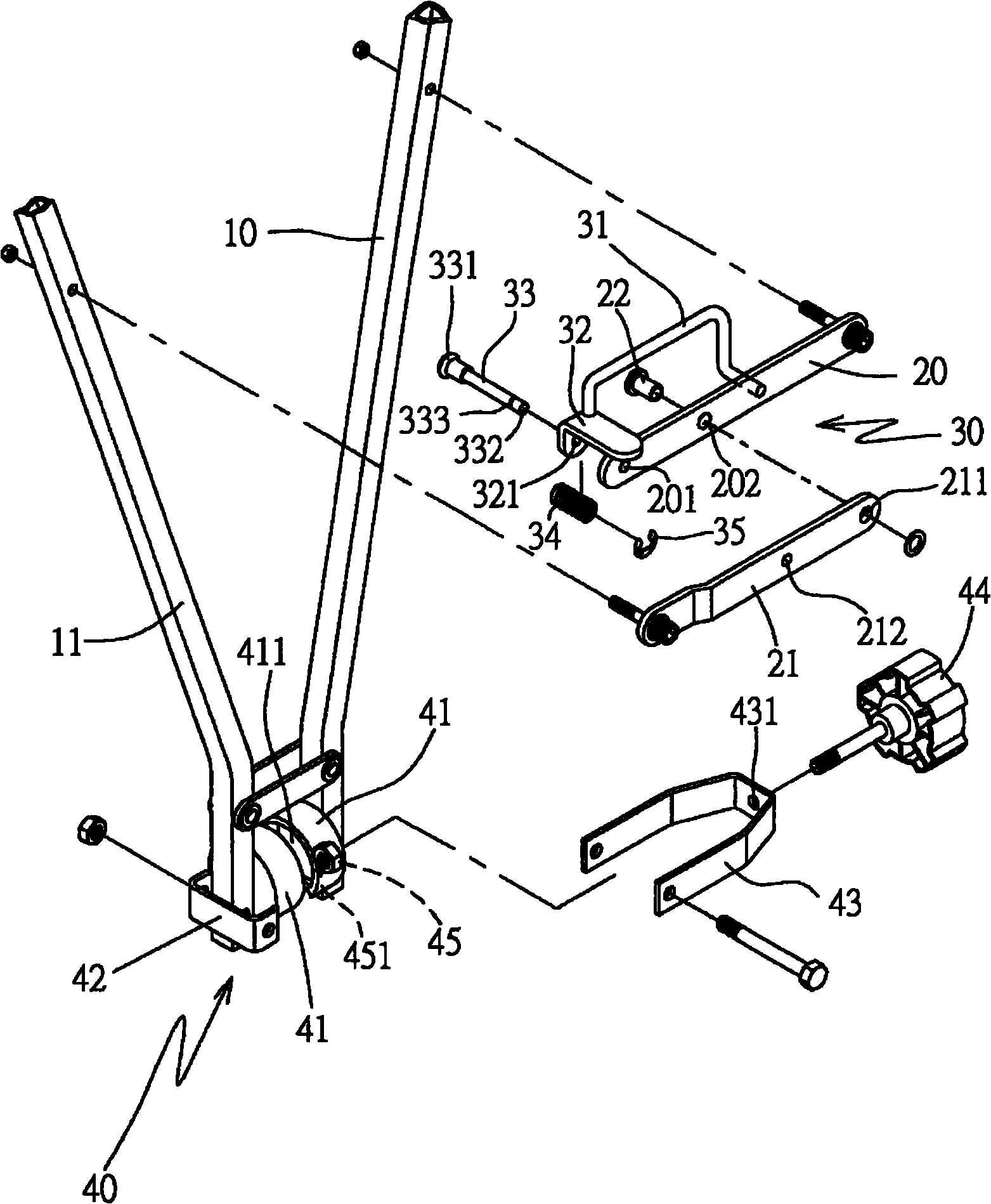

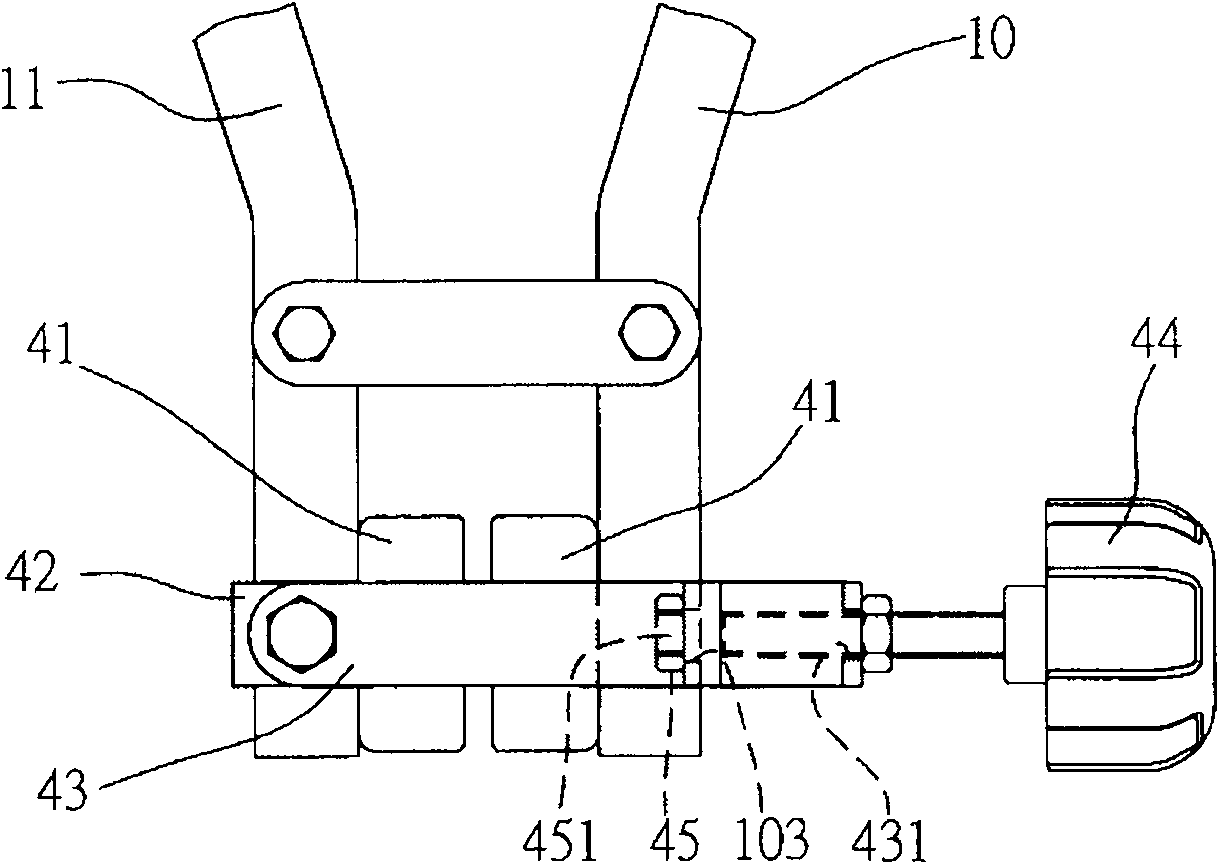

[0030] see Figures 1 to 4 The shown diagram of a preferred embodiment of the present invention is a frame structure and an anti-shake structure of the present invention, and its composition includes:

[0031] The two poles are first and second poles 10 and 11 having corresponding shapes, and the bottoms of the first and second poles 10 and 11 are pivotally connected to each other;

[0032]The two outer supports have first and second outer supports 20 and 21 pivotally connected to each other, which are assembled between the first and second support rods 10 and 11 and spread horizontally. ; wherein one end of the first outer support member 20 is pivotally connected to the appropriate position of the first pole 10, and the other end is respectively provided with first and second through holes 201, 202; One...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap