Blowing apparatus for expanding containers

A technology for blow molding equipment and blow molding containers, which is used in the fields of blow molding containers and blow molding equipment to ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

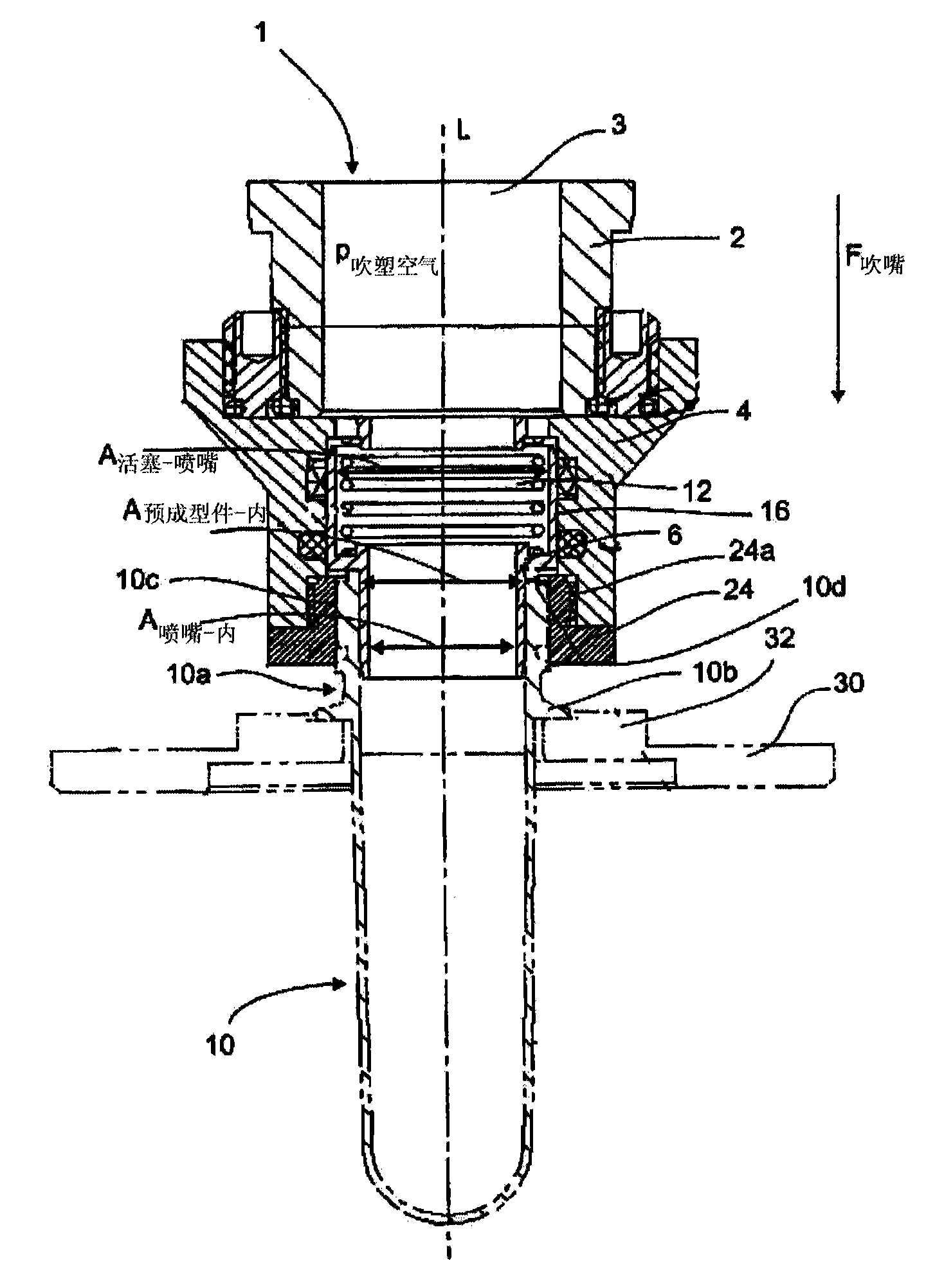

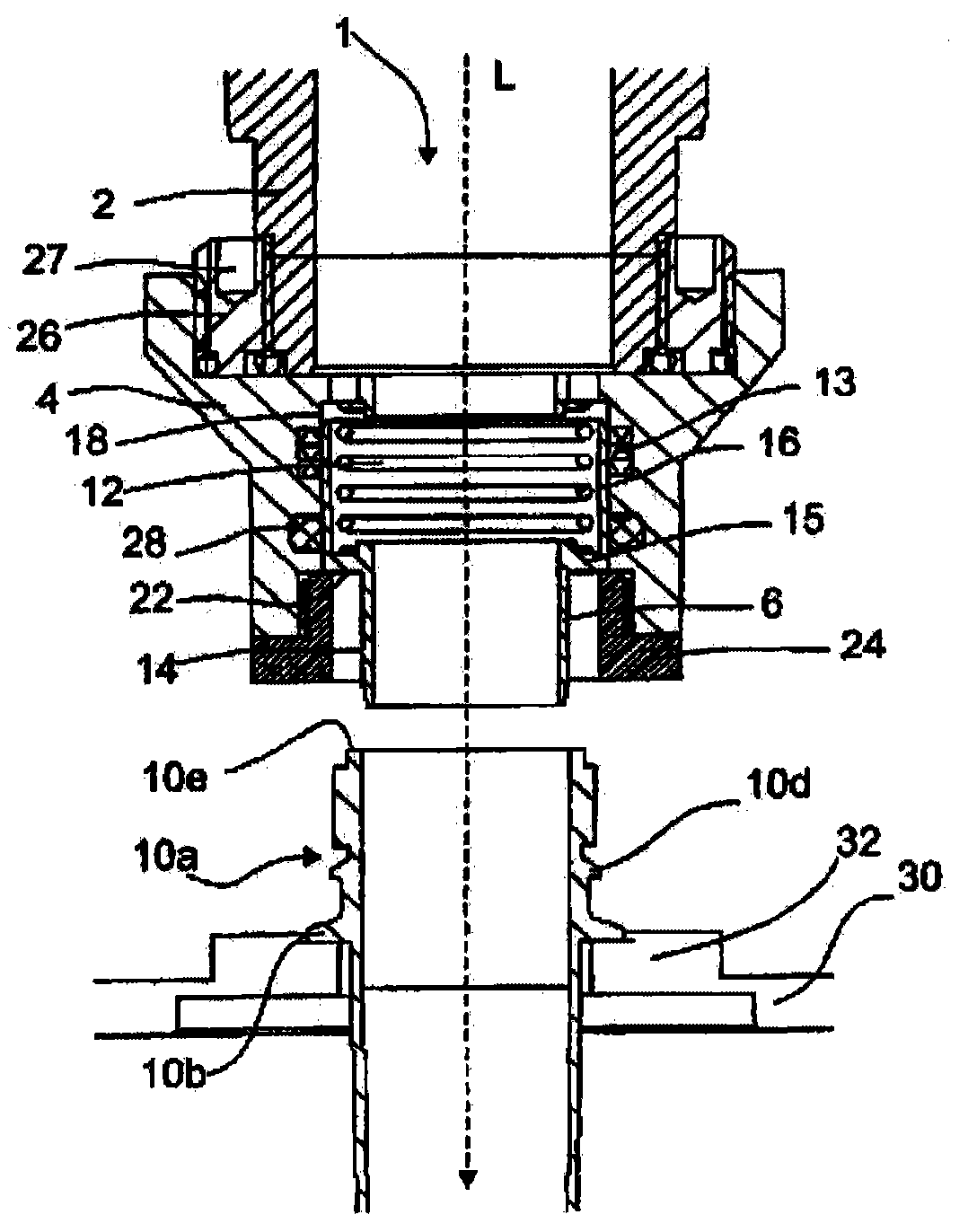

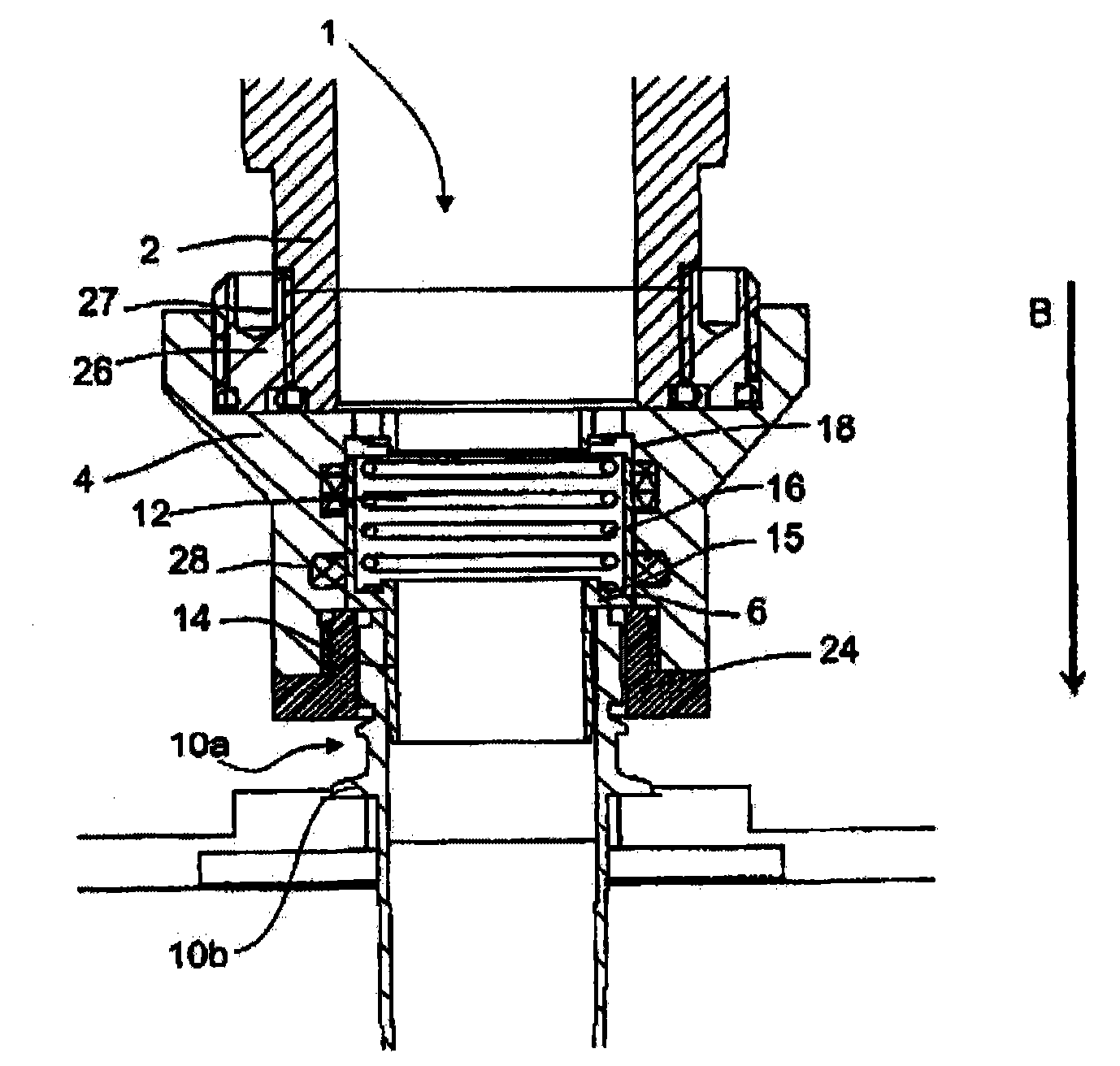

[0036] figure 1A blow molding device 1 according to a first embodiment of the invention is shown. The blow molding device 1 includes a blow molding piston 2 . The blowing piston 2 is moved by means of a guide cam (not shown) into a specific (end) position in which a preform is supplied with compressed air and thus inflated into a container 10 . The container 10 is placed in a blow mold (not shown) with the aid of a central disc 30 . Reference 32 indicates a protrusion on the central disk 30 which supports the support ring 10b of the container. Reference 10a indicates the entire opening of the container 10 . A screw thread 10c and a promotion ring 10d are provided on the opening 10a.

[0037] A guiding device 4 is detachably mounted on the blow molding piston 2 . A blowing nozzle 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com