Timepiece

A technology for clocks and clock movements, applied in the field of clocks, can solve the problems of impossible to fit gears, difficult to assemble, heavy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

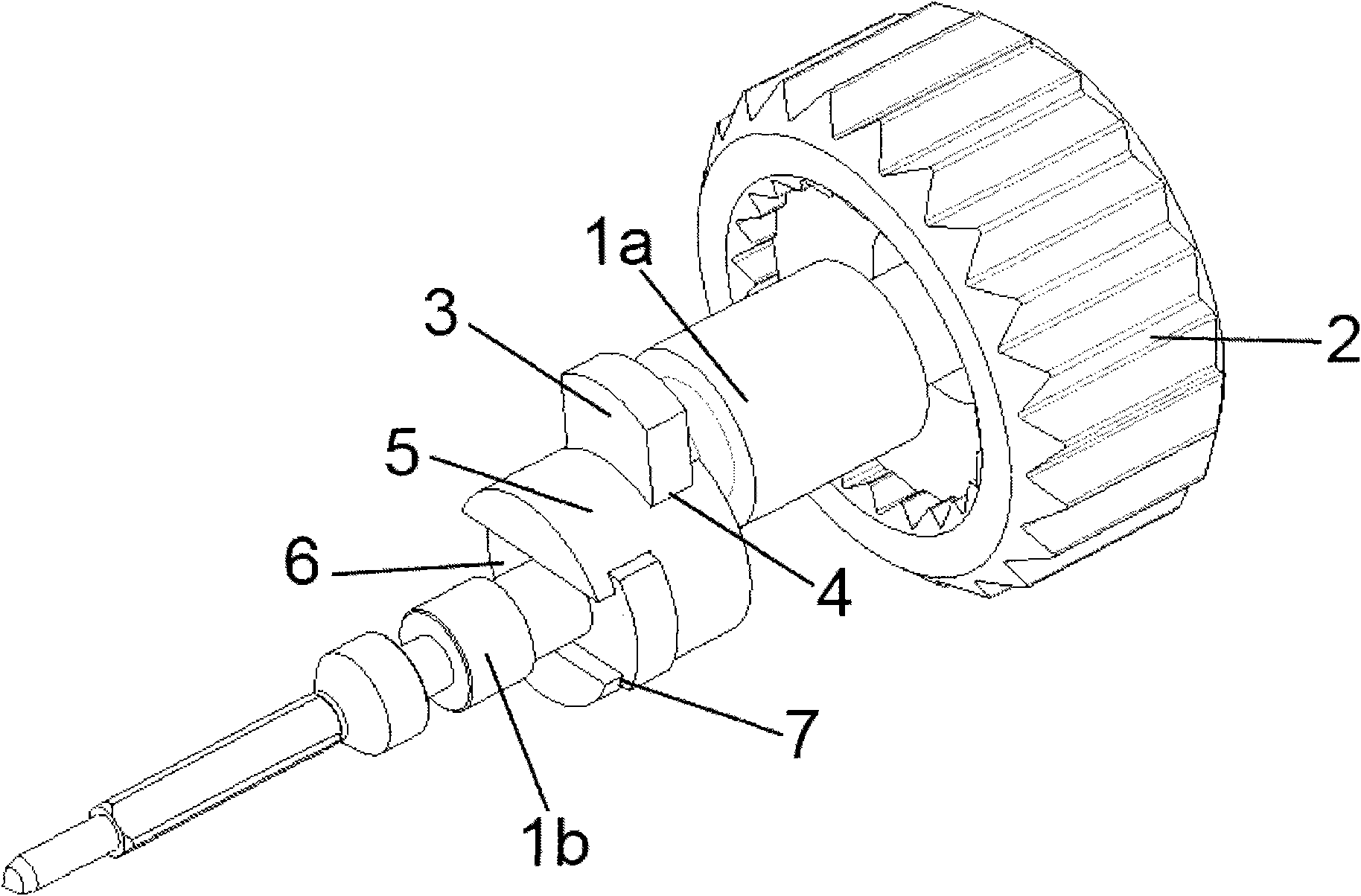

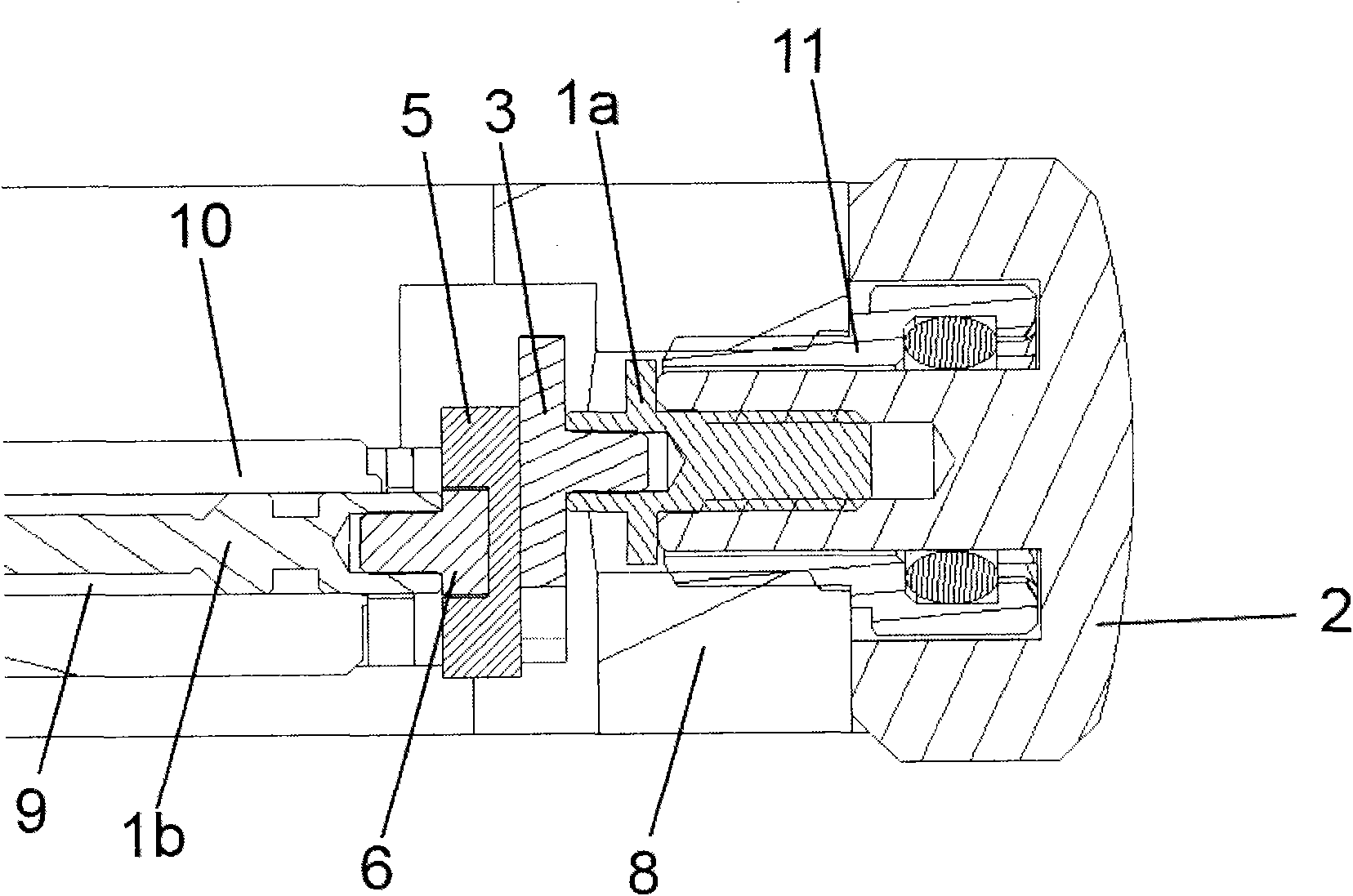

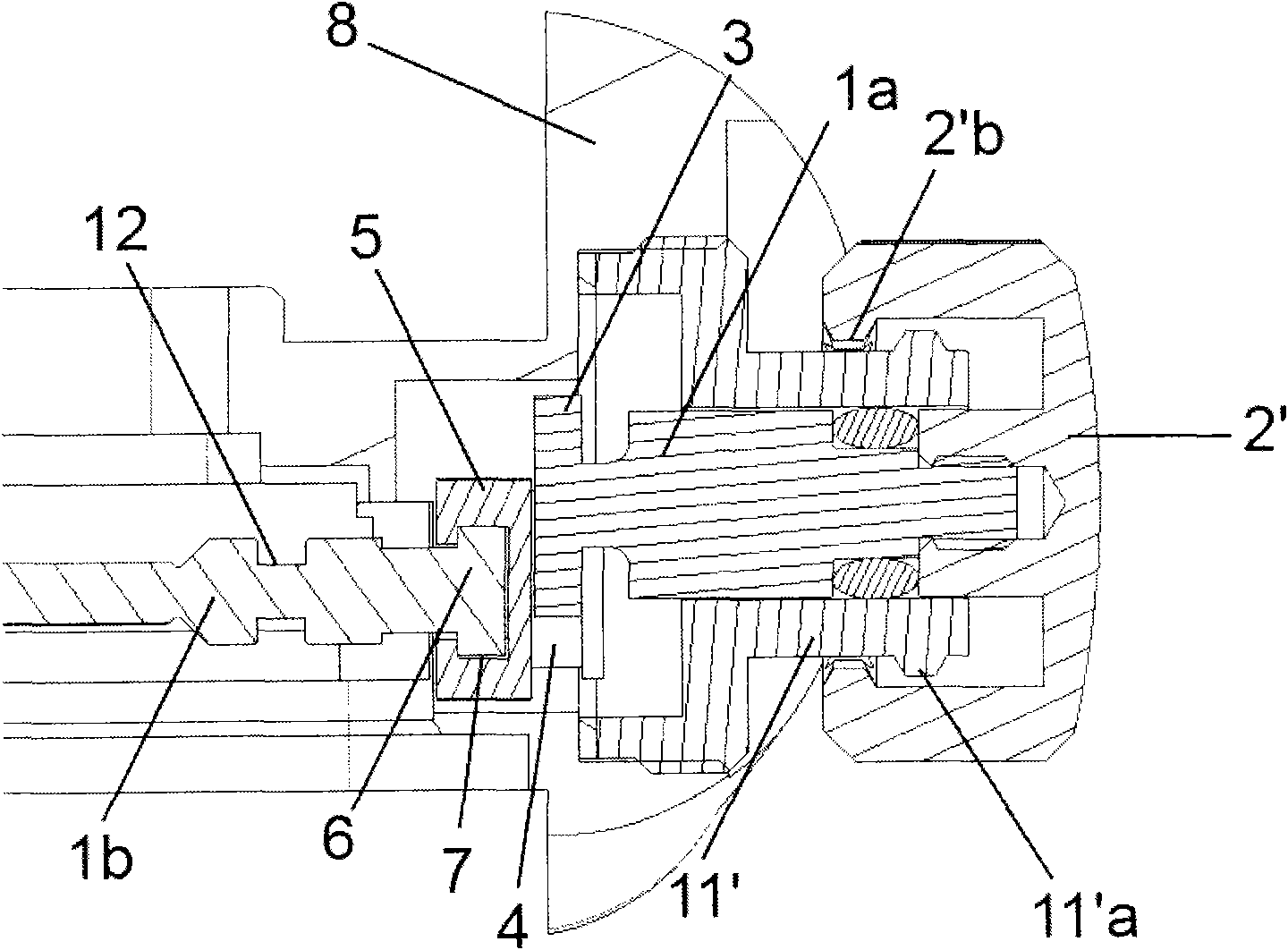

[0015] figure 1 The transmission mechanism shown has two parallel-axis bull cores 1a and 1b. One end of the caliber 1a is connected to the central arbor (not shown in the figure) designed to drive the crown 2 on the outside of the case. The other end of the hub 1a is connected to a sliding member 3 engaged in a slide rail 4 formed in one surface of the link 5 and extending perpendicular to the axis of the hub 1a.

[0016] One end of the hub 1b adjacent to the hub 1a is connected to a sliding member 6 engaged in a slide rail 7 formed on the other surface of the connecting rod 5 and also extending perpendicular to the axis of the hub 1b. Since the two cores 1a and 1b are parallel, the two slide rails 4 and 7 are also parallel. However, the orientation of these slide rails 4 and 7 is perpendicular to each other. In order to allow sliding between the sliding element and the respective sliding rail, the cross-section of the sliding element and the respective sliding rail are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com