Composite heat exchanger end structure

A technology of heat exchanger and end structure, which is applied in the direction of heat exchange equipment, heat exchanger shell, indirect heat exchanger, etc., and can solve problems such as difficult sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

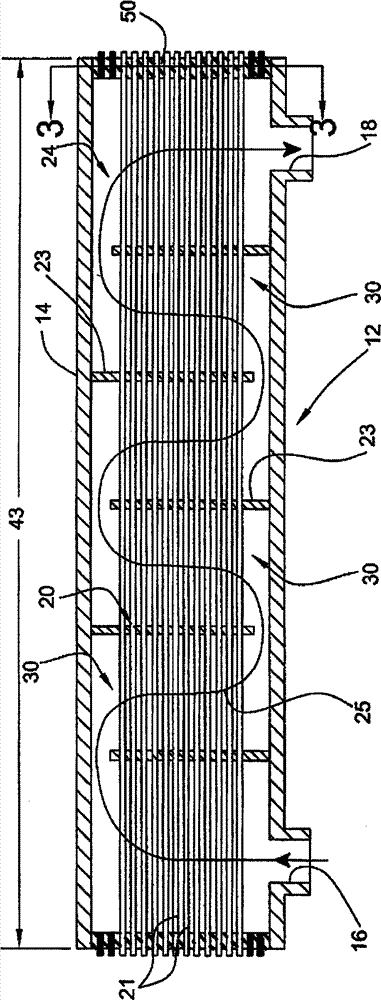

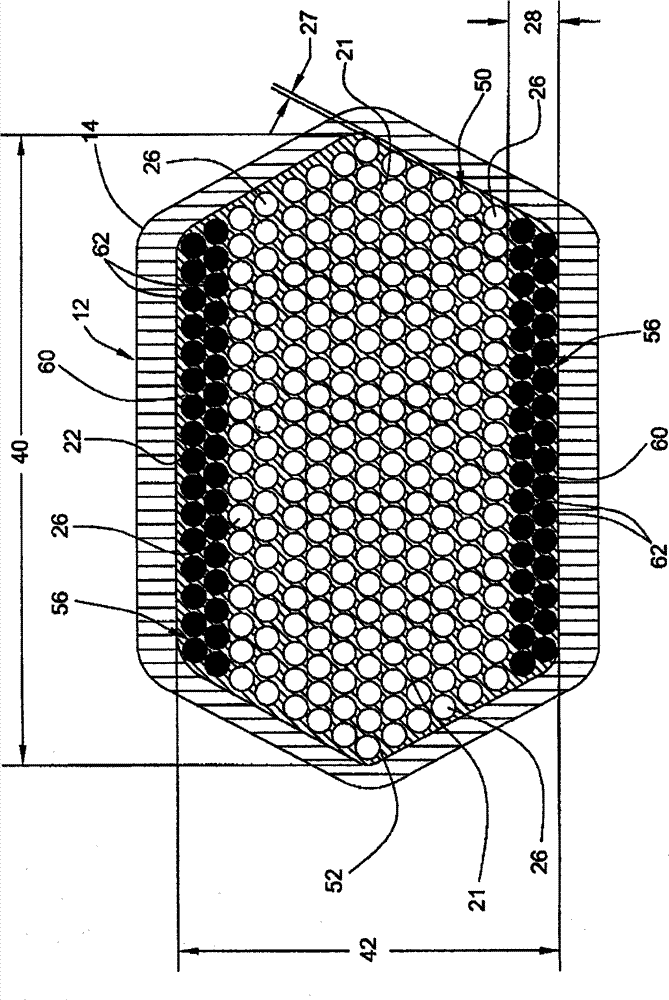

[0012] The present disclosure relates to a heat exchanger having a bundle of tubes disposed within a housing with resilient end structures at least partially spanning a heat exchange chamber disposed in compressed, plug-forming relationship . The resilient end structure includes one or more boundary segments extending between the inner wall of the shell and the perimeter of the tube bundle. The boundary segment comprises a combination of materials having different compressive properties that provide enhanced support to the boundary segment.

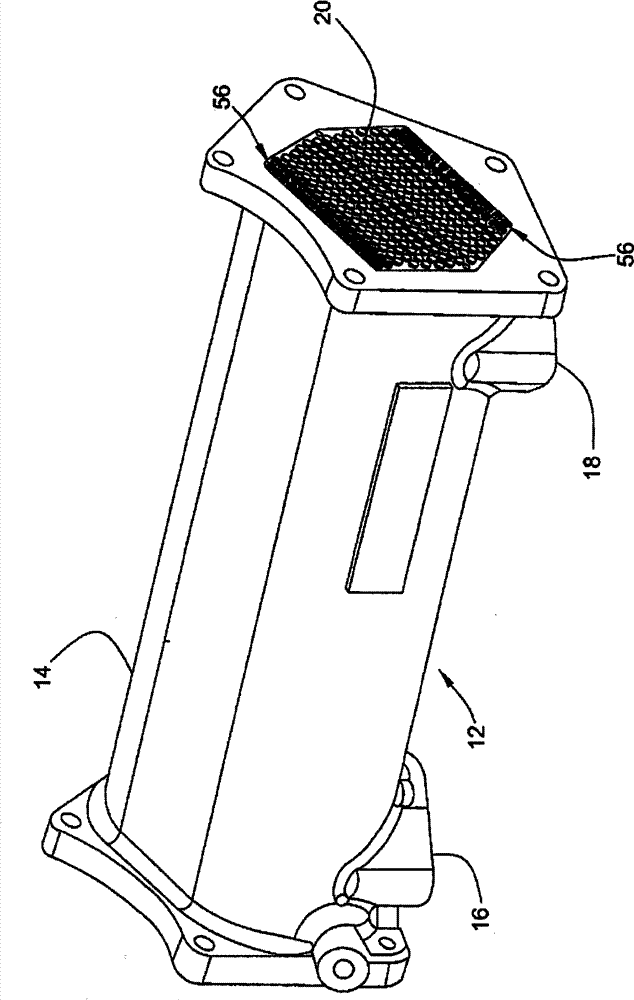

[0013] Reference will now be made to the drawings, wherein like reference numerals represent like elements throughout the several views. figure 1 An exemplary heat exchanger 12 is shown, such as an oil cooler or the like. In this regard, it should be understood that although heat exchanger 12 is shown in the form of an oil cooler such as may be used on an internal combustion engine, heat exchanger 12 is in no way limited to this configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com