Method for automatically controlling an internal combustion engine

一种内燃机、旋转角度的技术,应用在内燃活塞发动机、阀控制、电子控制等方向,达到省去机械控制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

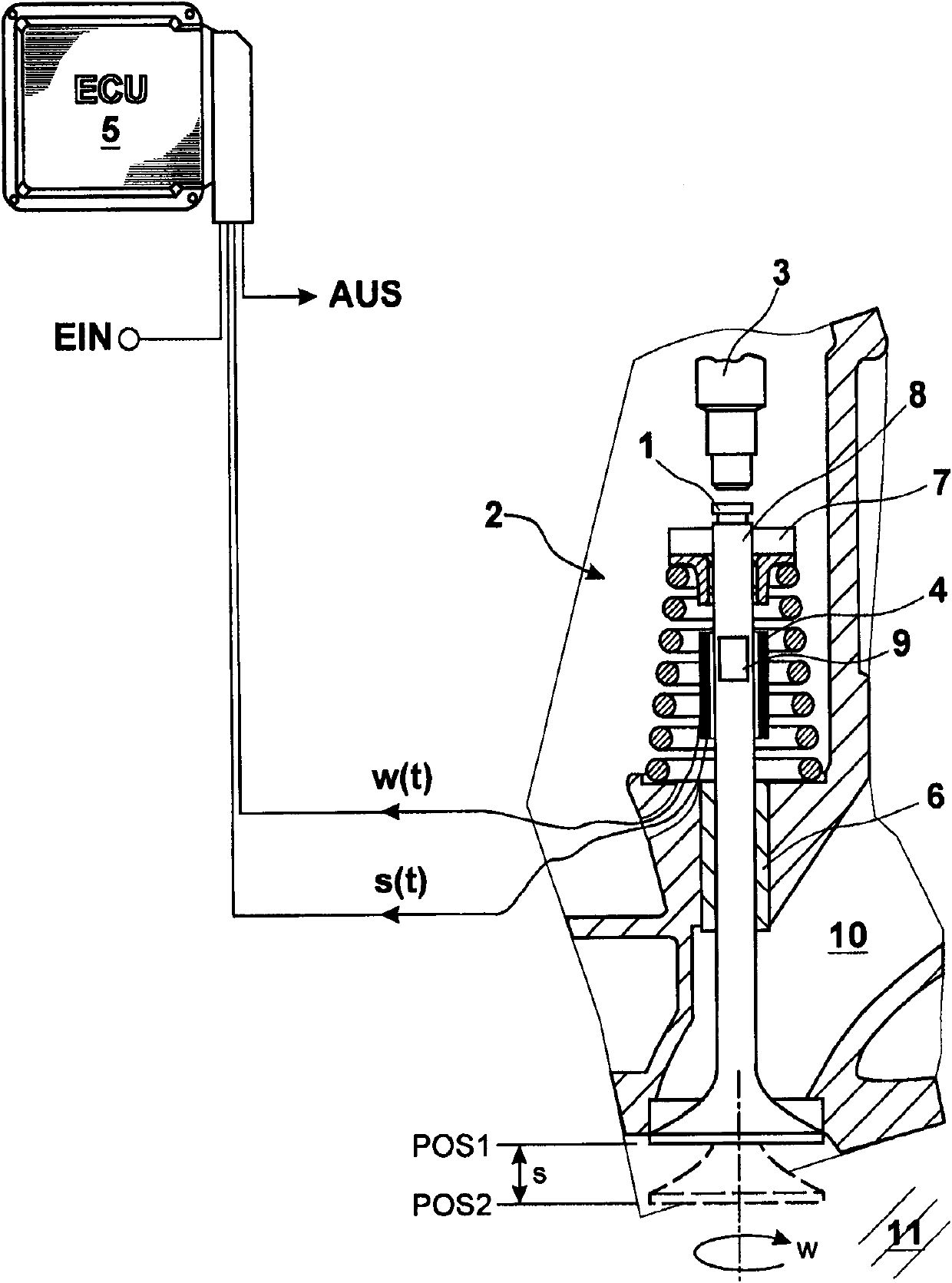

[0028] figure 1 Shows a system diagram with a combined sensor for travel and angle of rotation measurement at the gas exchange valve 1 . The components shown are: a gas exchange valve 1 , eg an exhaust valve, a cylinder head 2 , a rocker arm 3 for actuating the gas exchange valve 1 , a sensor 4 and an electronic control unit 5 (ECU). The gas exchange valve 1 is inserted into the cylinder head 2 via a guide tube 6 and is actuated via a rocker arm 3 . By means of the swivel device 7 , the gas exchange valve 1 is simultaneously rotated through an angle during actuation, whereby deposits on the gas exchange valve 1 are prevented. In the first position POS1 the gas exchange valve 1 completely closes the combustion chamber 11 . In the second position POS2 , the gas exchange valve 1 opens the passage from the combustion chamber 11 to the exhaust tract 10 , through which passage the exhaust gas then flows, for example, to the exhaust gas turbocharger. The sensor 4 simultaneously de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com