Washing machine capable of adjusting water injection direction and water injection method thereof

A washing machine and adjustable technology, applied in the field of washing machines, can solve the problems of automatically changing the direction of water injection, failing to achieve humanization, etc., and achieve the effects of clean rinsing and uniform water injection in washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

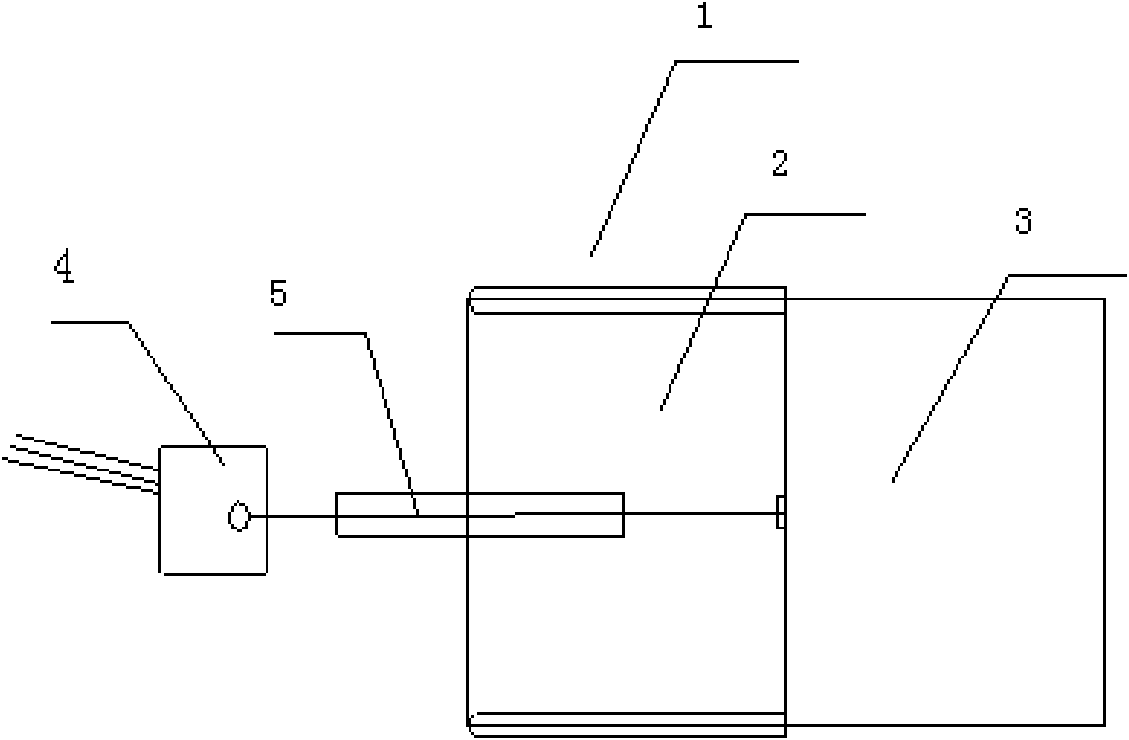

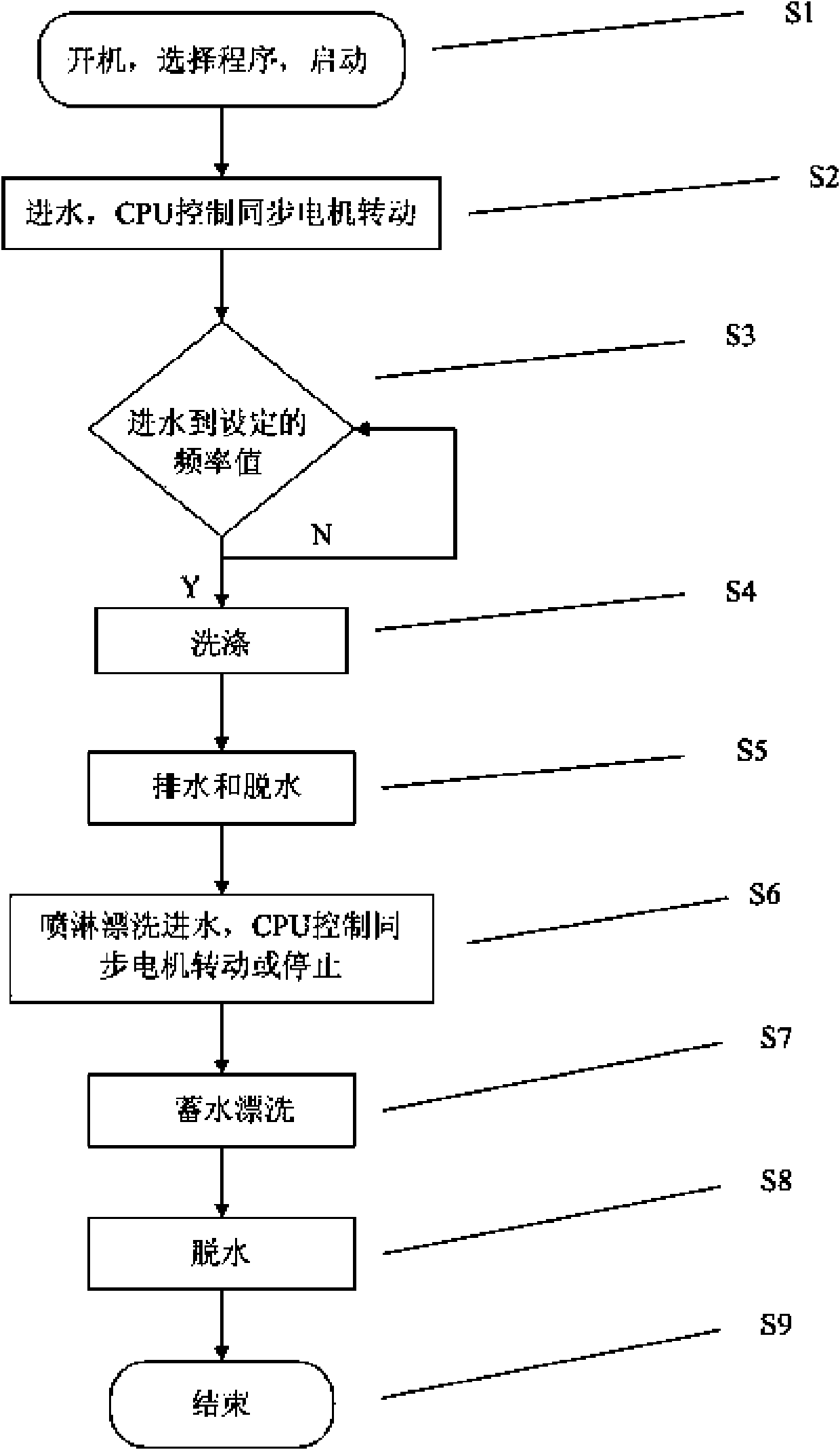

[0023] figure 1 The parts represented by the marks are: 1 water injection box, 2 fixed water baffle, 3 water baffle, 4 synchronous motor, 5 tractor;

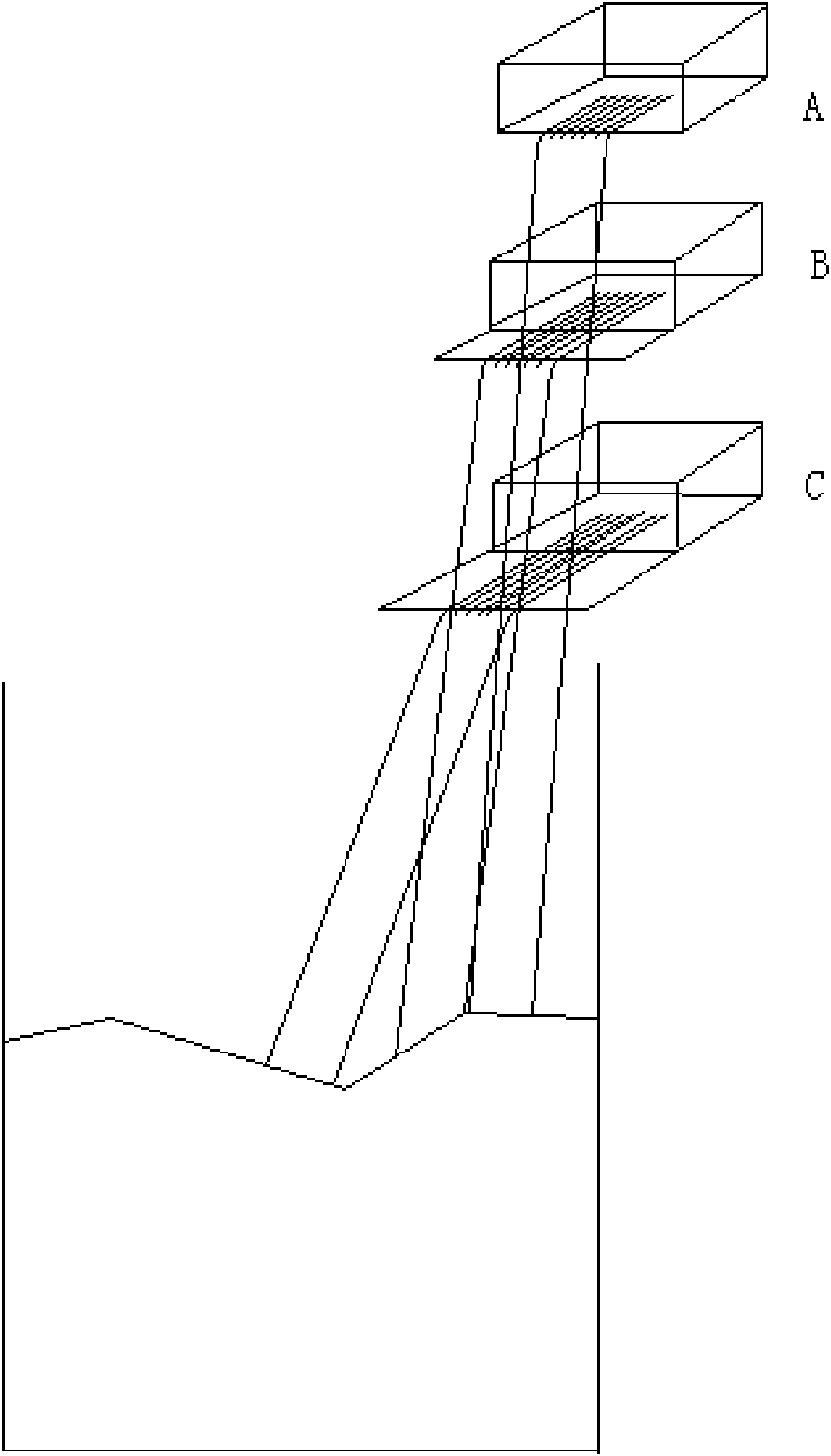

[0024] figure 2 The schematic diagram of the water injection direction of the water retaining sheet in different positions is shown in , where: A is the water injection direction when the water retaining sheet is not popped out at the original position; Pop out, and the water injection changes direction a lot.

[0025] see figure 1 , figure 2 The washing machine provided by the invention comprises an outer tub, a water inlet valve, a computer program controller (not shown), an inner tub for washing and dehydration, and a water injection box, and a water injection adjustment unit is installed on the water retaining plate of the water injection box. The water injection adjustment unit is composed of a retractable water stop, a tractor and a synchronous motor. Tracks are installed on the water stop of the water injection box,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com