Fixing member, protective member, and fixing method for member to be fixed

A technology for fixing components and protecting components, applied in the direction of connecting components, fasteners, applications, etc., can solve problems such as reduced operating efficiency and increased burden on operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

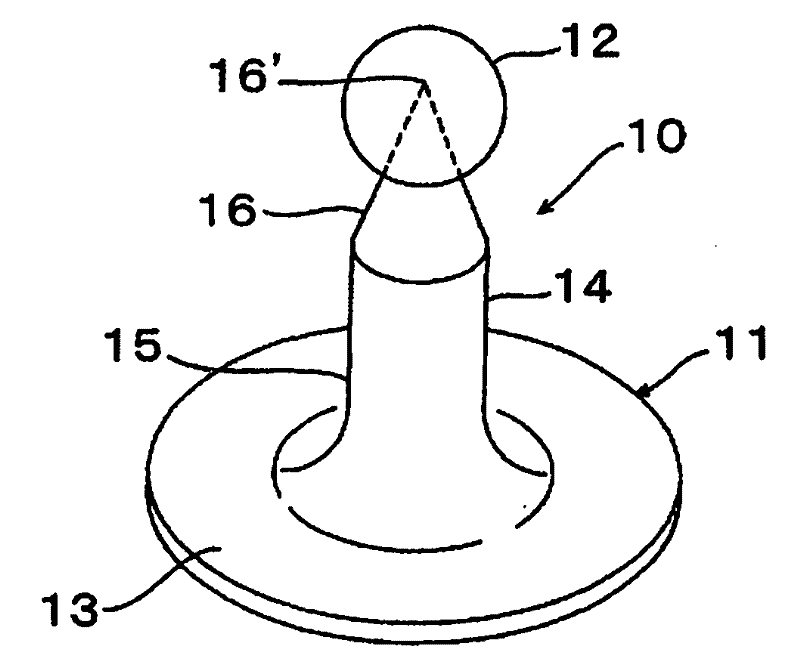

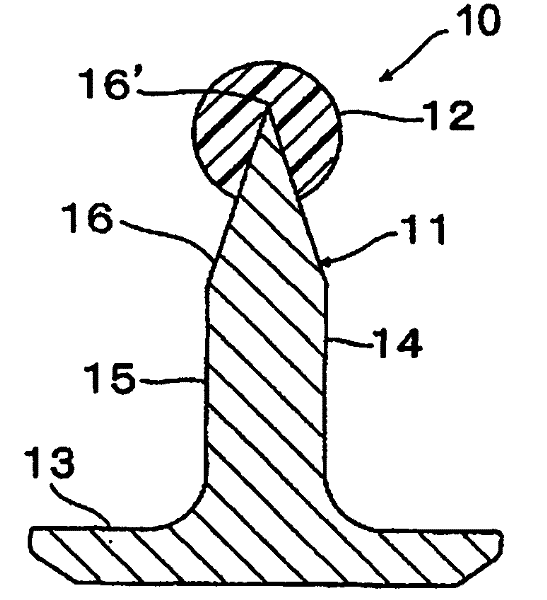

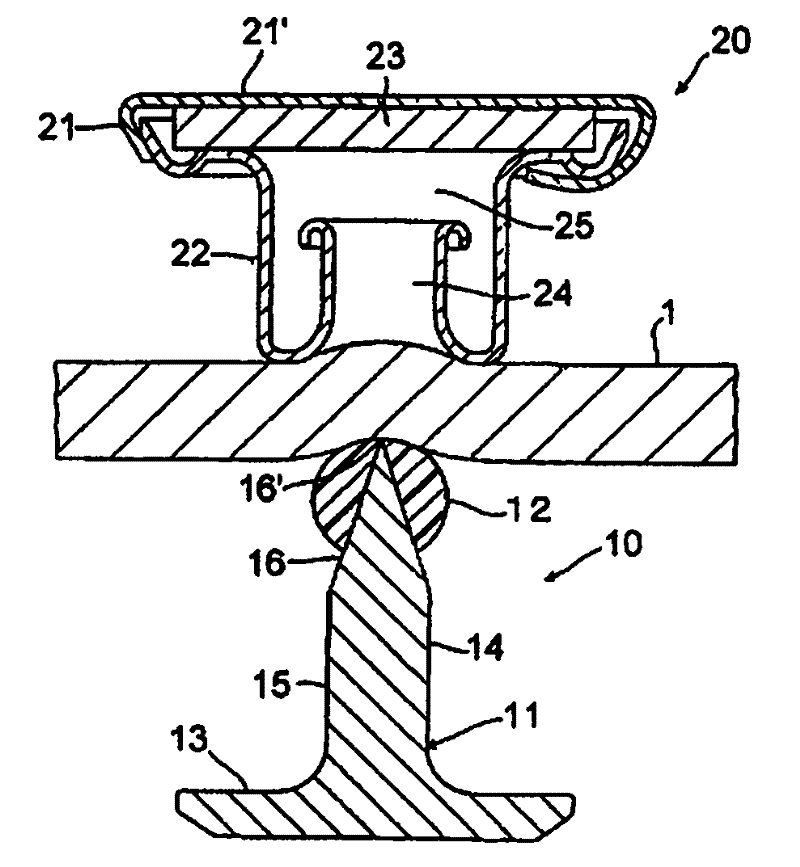

[0028] Next, preferred embodiments of the present invention will be described with reference to the drawings. Figure 1 ~ Figure 4 It is an example of a clip 10 for a button as a fixing member according to an embodiment of the present invention, that is, a clip for fixing a button 20 as a member to be fixed to a cloth 1 as a sheet, figure 1 and figure 2 It is a perspective view and a longitudinal sectional view of the clip 10 for buttons. The clip 10 for a button is composed of a clip body 11 made of metal and a protective member 12 made of an elastomeric resin of the present invention molded and fixed to a front end 16' of a penetration portion 14 of the clip body 11 which will be described later. The clip main body 11 itself is the same part as the conventional product, and has a through portion 14 and a disc-shaped base portion 13, and the through portion 14 is upward from the base portion 13 (direction according figure 2 etc.) protrudes concentrically with the base por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com