Arrangement for mounting front technical surface of vehicle

A technique of vehicles, technology, applied in the field of arrangement of mechanical elements, able to solve problems such as not fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, the same reference numerals denote components having the same or similar functions.

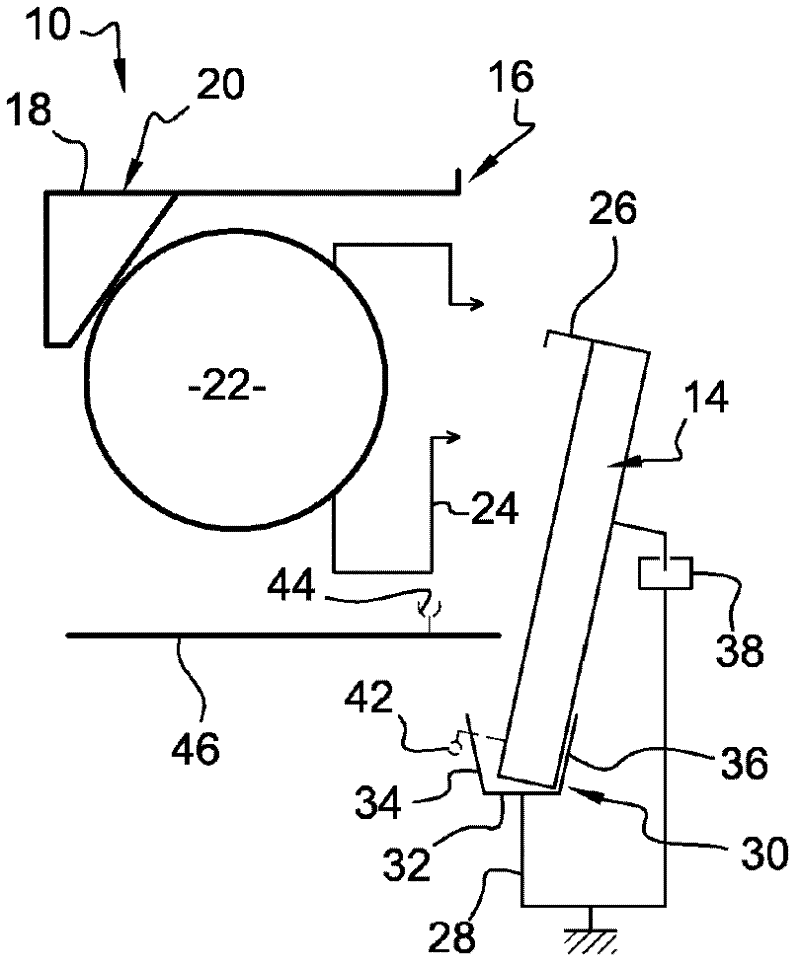

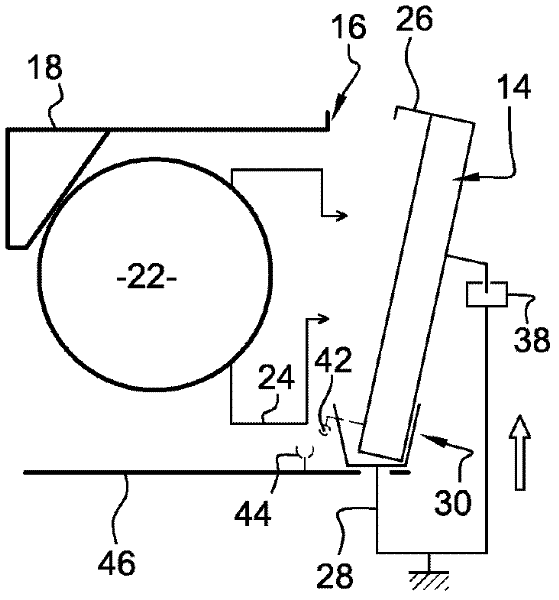

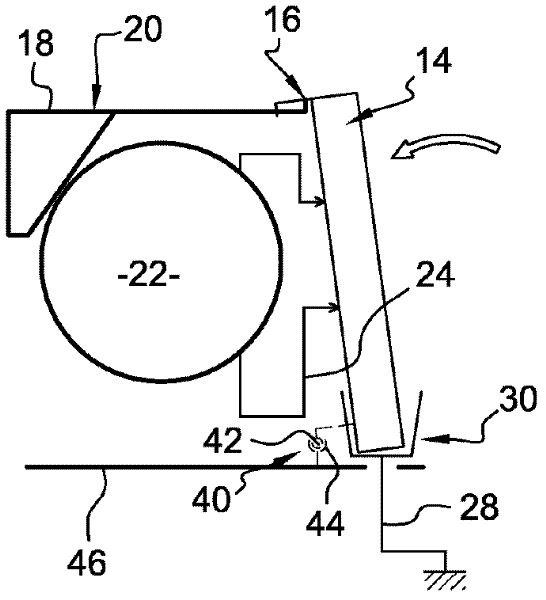

[0026] figure 1 An arrangement 10 is shown for mounting, on an assembly line of a motor vehicle 20 , a substantially vertical mechanical element 14 , referred to as a “front technical surface”, onto a transverse structural element 16 of a body 18 of the vehicle 20 .

[0027] The body 18 of the vehicle 20 receives, for example, the propulsion unit 22, and the mechanical element 14, referred to as the "front technical surface", includes, for example, at least one cooling radiator (not shown), as Figure 4 As shown, the cooling radiator is intended to be connected to the propulsion unit 22 by at least one connection element 24 such as a pipe or a cable.

[0028] The transverse structural element 16 of the body 18 of the vehicle 20 is, for example, the upper cross member 16 of the body 18 of the vehicle 20 .

[0029] In known manner, the mechanical element 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com