Demoulding mechanism for semicircular bend die

A demoulding mechanism and semi-circular technology, applied in the field of plastic molds, can solve the problems of unsmooth circulation, less water storage space, and inconvenient installation, and achieve the effect of smooth sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

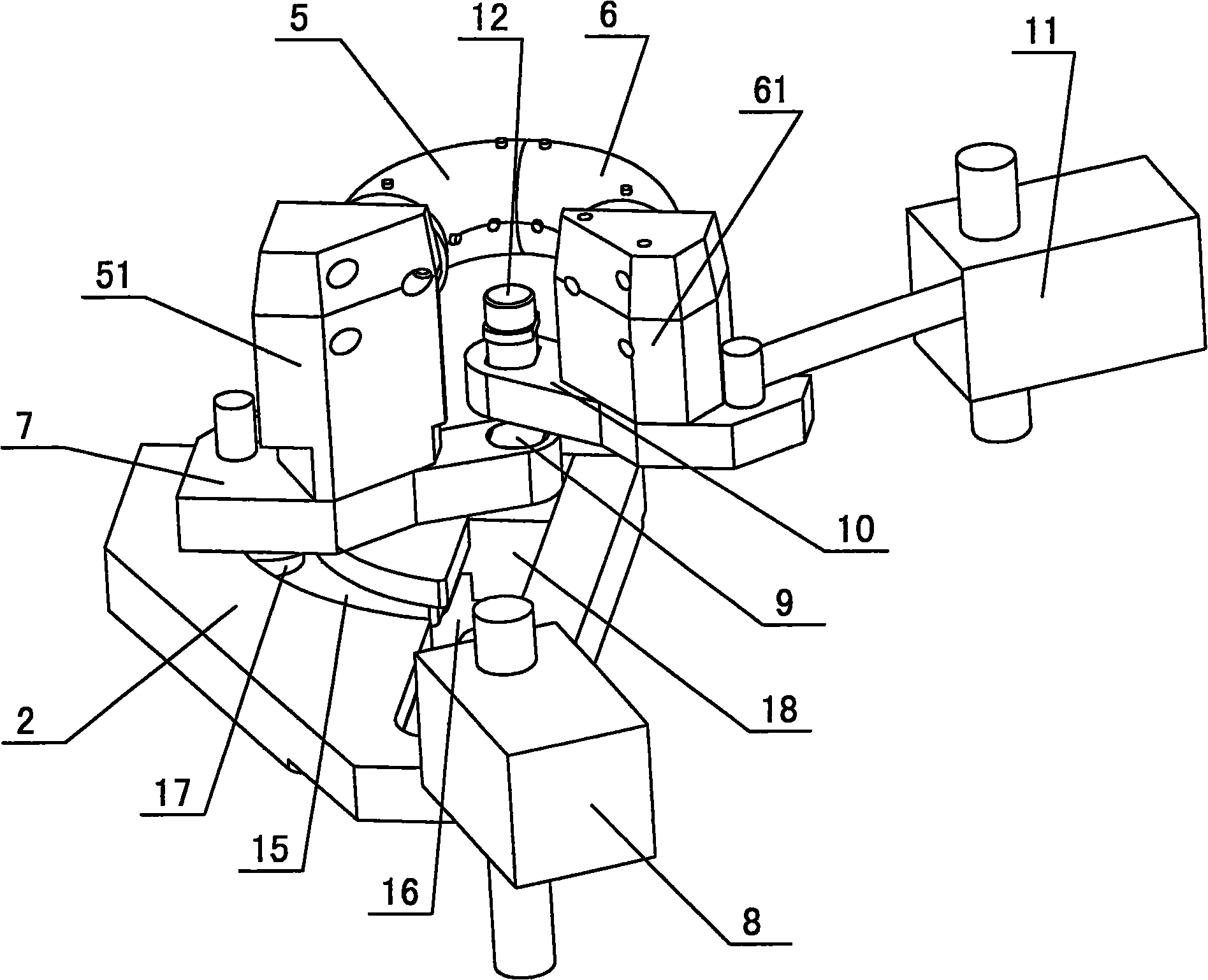

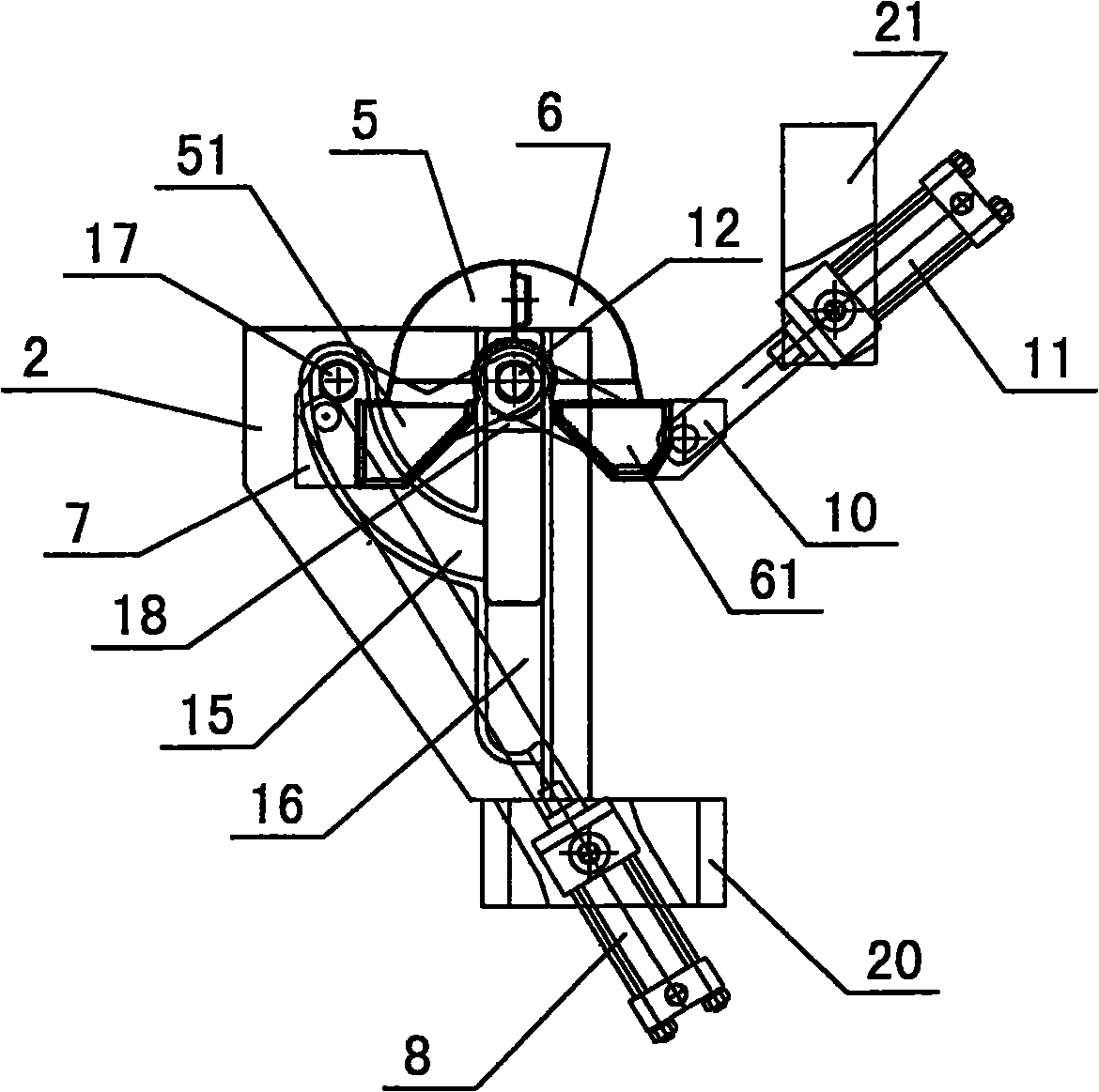

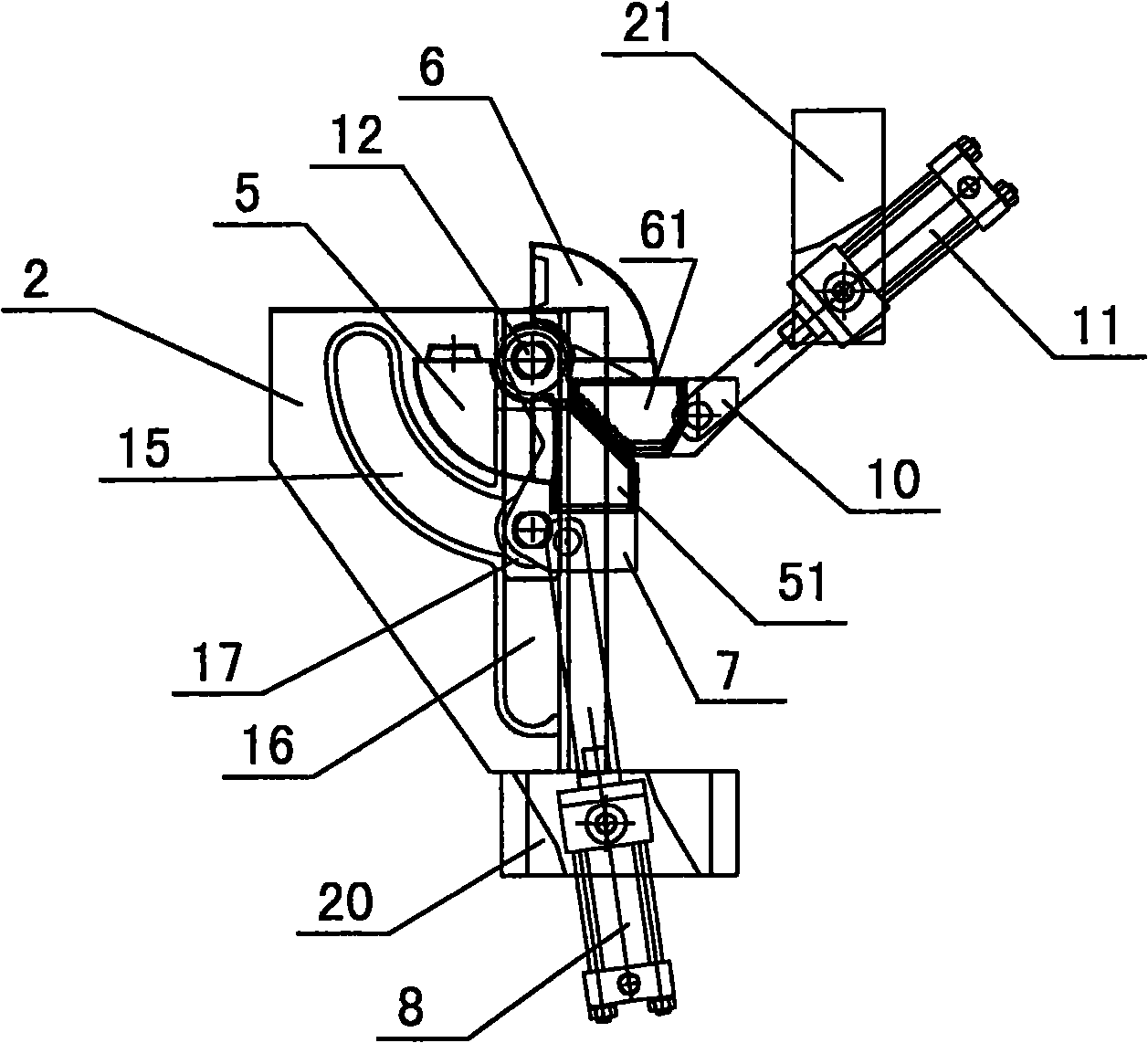

[0013] The invention relates to a semicircular elbow mold demoulding mechanism, such as Figure 1-Figure 6 As shown, it includes a mold bottom plate 1, a cavity frame 2 is installed on the bottom plate, a cavity insert 3 is installed on the cavity frame, and a semicircular elbow cavity is formed in the cavity insert, and the semicircular elbow type There is a formed semicircular elbow in the cavity, and the inner wall of the semicircular elbow has a semicircular elbow core, which is characterized in that the semicircular elbow core includes A arc core 5 and B arc core. Shaped core 6 is made up of, and the outer end of described A curved core 5 is connected with A core rotating plate 7, and A core rotating plate 7 is driven by A swing oil cylinder 8 to rotate around A circle center fulcrum 9, and described A circle center fulcrum 9 is slidingly arranged in the cavity mold frame 2, and is driven by the A swing cylinder 8 through the A core rotating plate 7 to slide linearly in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com