Flat wiper blade

A wiper and scraper technology, which is applied in the field of flat wiper scrapers, can solve the problems of high assembly cost and large expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

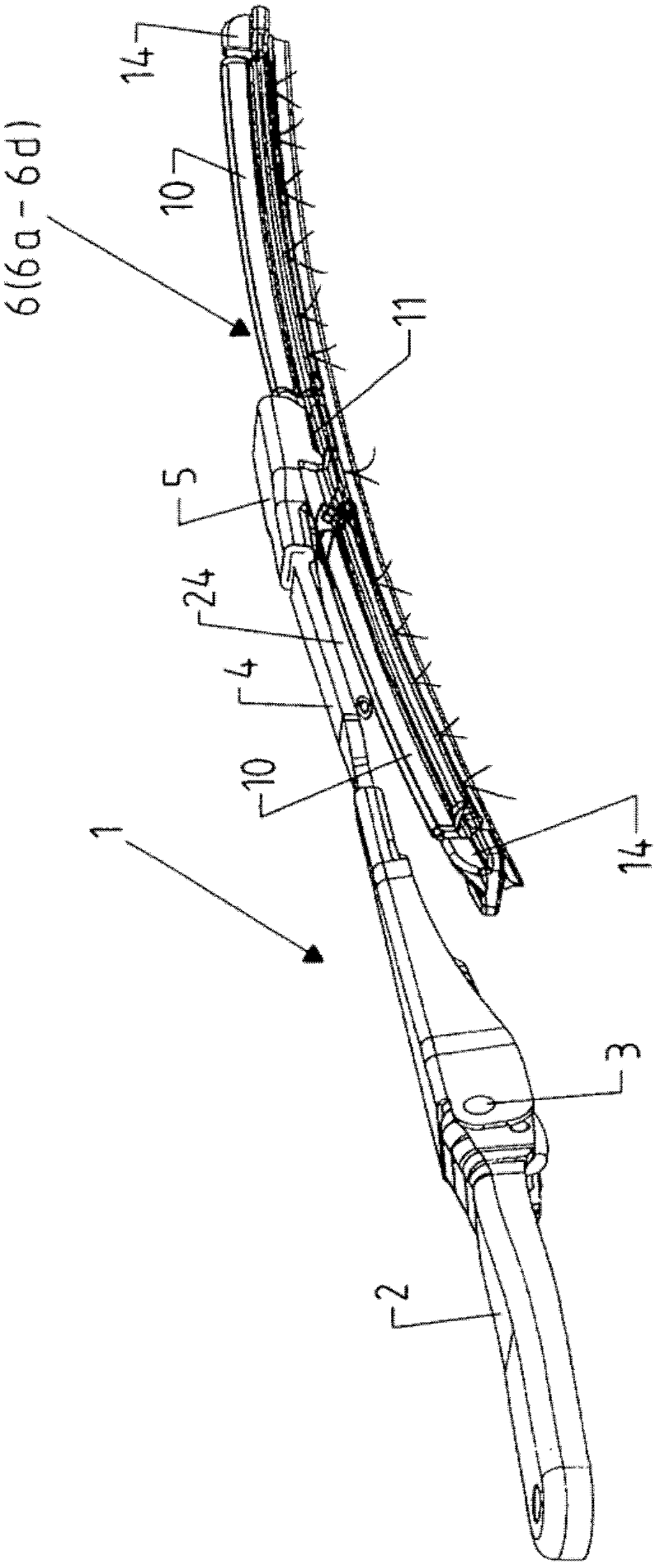

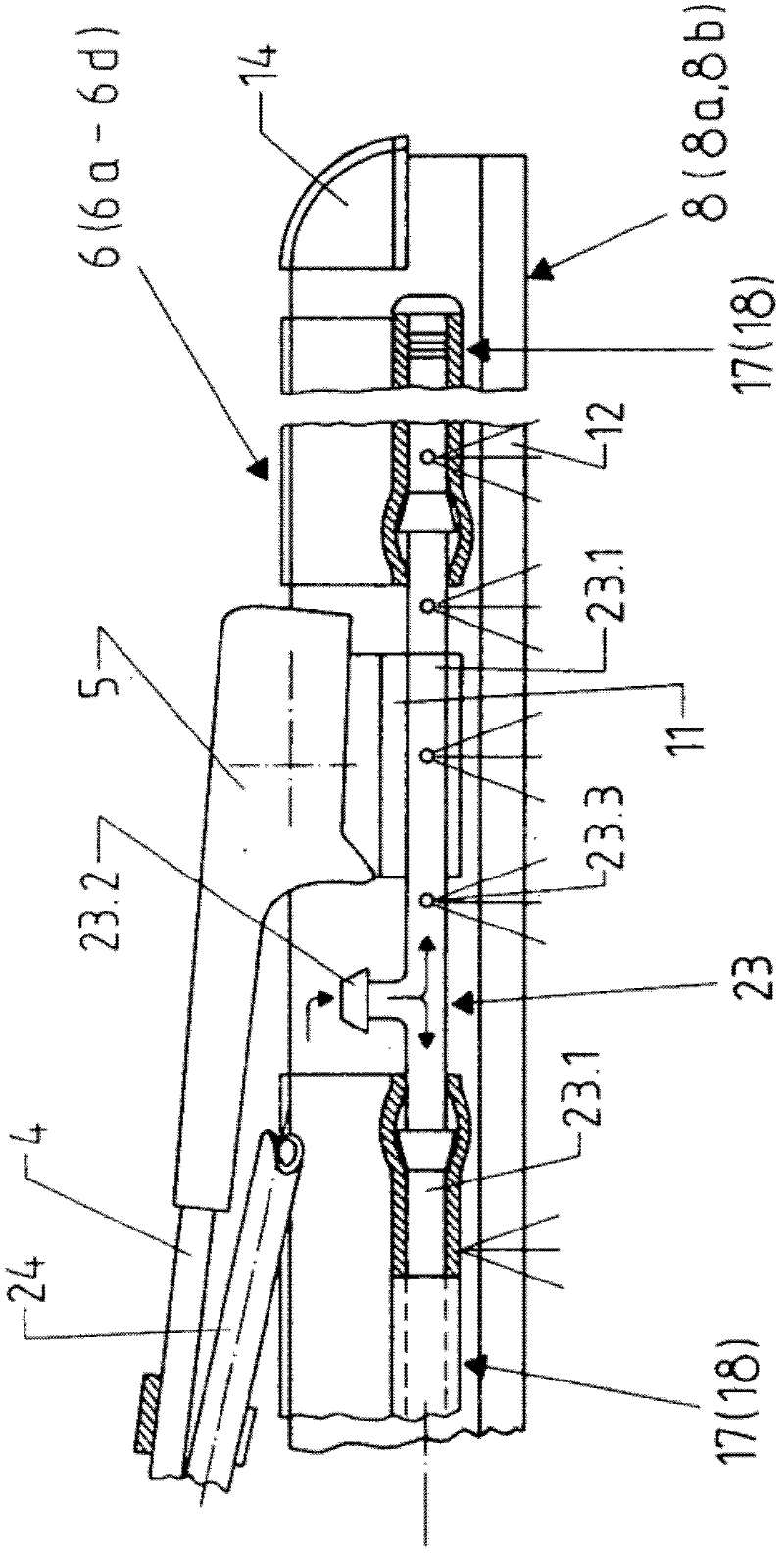

[0022] exist Figure 1-7 Among them, 1 is the wiper arm of the windshield wiper module for the vehicle windshield FS, especially for the front windshield of the vehicle. The wiper arm 1 comprises, in a known manner, a pivot part 2 and a wiper arm element 4 (wiper lever), via which the wiper arm 1 can be mounted on a not shown wiper shaft, which A wiper arm element 4 is hinged on the pivot part 2 via a wiper arm link 3, said wiper arm element being provided at its end remote from the pivot part 2 with a wiper-side adapter 5 for wiping Removable flexible fixation of wiper blades, e.g. image 3 Wiper blade 6 in.

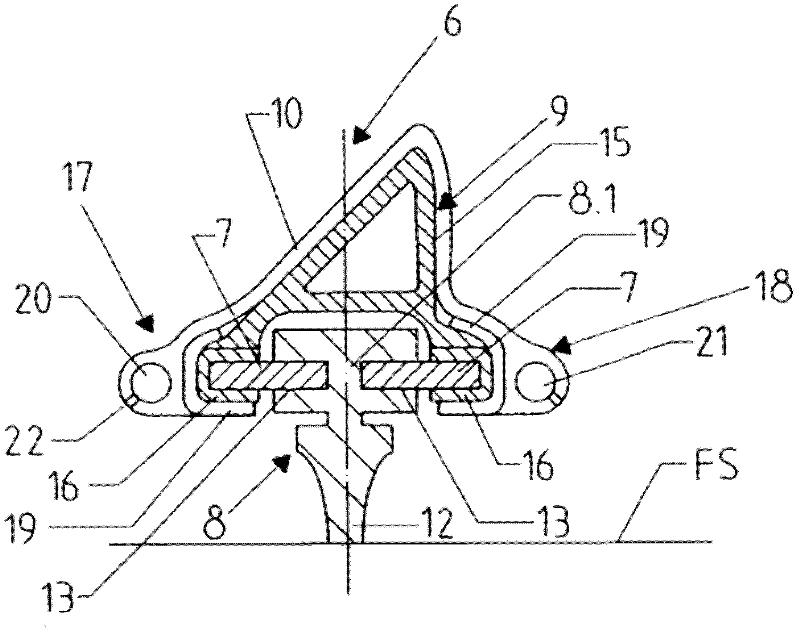

[0023] The wiper blade 6 is configured as a flat wiper blade and comprises for this purpose: at least two flat elastic rails 7 made of elastic metal material (for example spring steel); a wiper rubber 8; two spoilers two housing-shaped spoiler elements 10 forming the upper side of the wiper blade 6 ; and a wiper blade adapter 11 for detachable flexible connection to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com