Stocking sheathing tube for silk stocking heat transfer machine

A thermal transfer printing machine and silk stocking technology, applied in rotary printing machines, printing machines, transfer printing, etc., can solve problems such as uneven thermal transfer pressure, poor printing fastness, and unusable silk stockings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

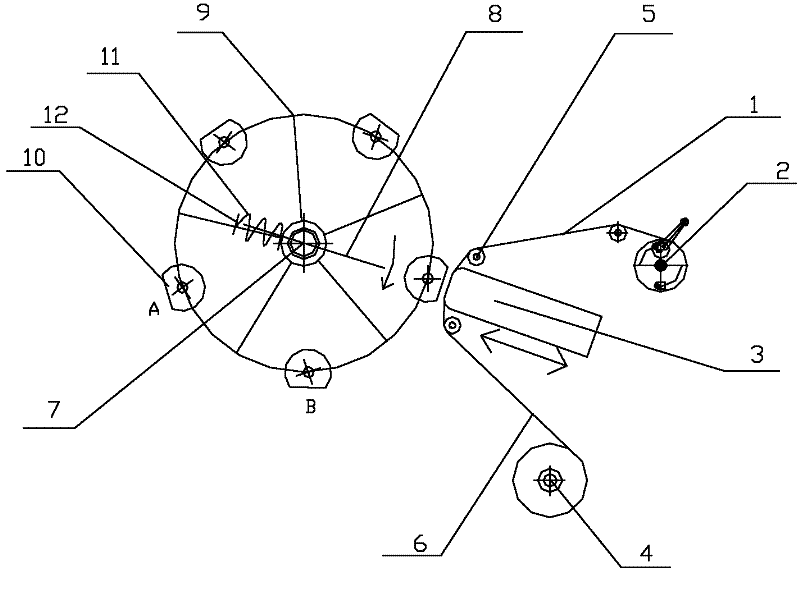

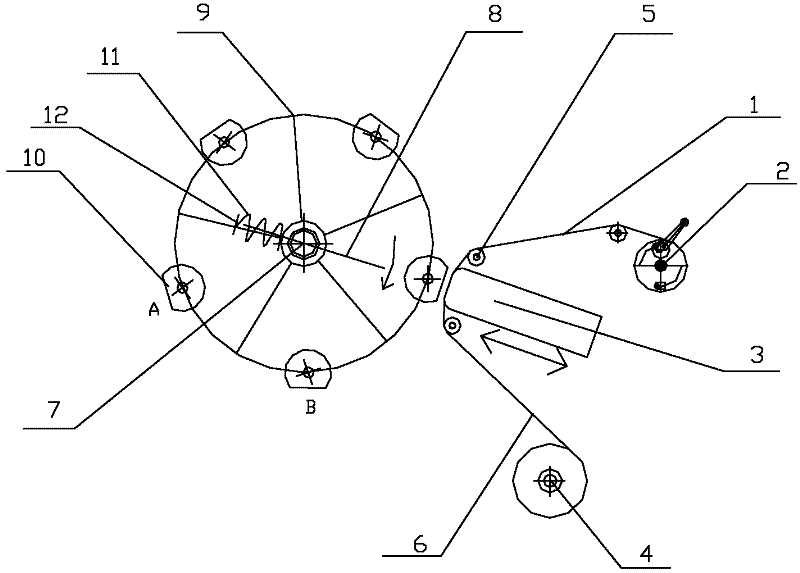

[0008] Referring to the accompanying drawings, this embodiment consists of a transfer part and a preheating part:

[0009] Transfer part: the transfer film 1 is wound on the transfer film unwinding frame 2, the transfer film 1 goes around the surface of the ironing head 3 through the guide wheel 5, the ironing head 3 can move in the direction of the arrow in the figure, and the transfer film 1 After the pattern transfer, the remaining bottom film 6 is rolled up on the bottom film winding frame 4, and the iron head 3 is heated internally, and the temperature of the iron head 3 is 120 plus or minus 2 degrees.

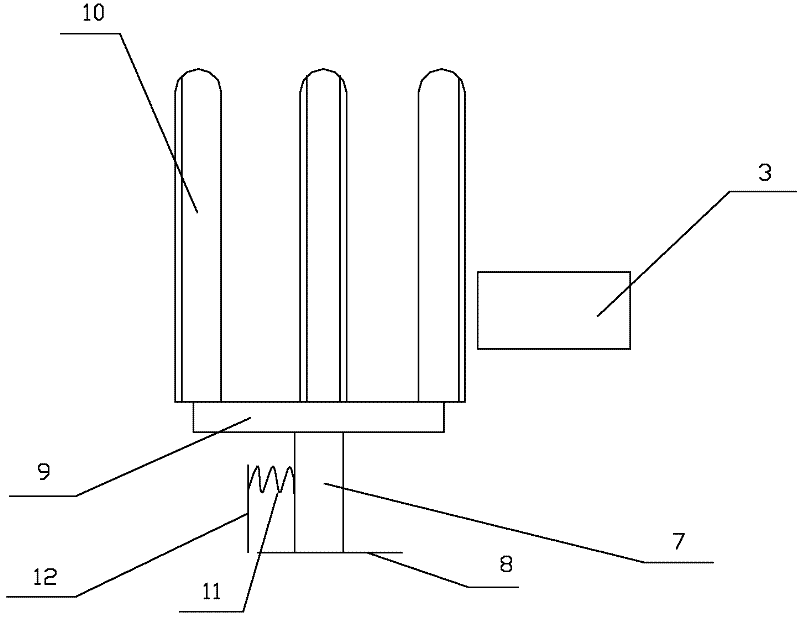

[0010] Preheating part: the base 7 is installed on the track 8 and can slide along the track 8, the bracket 9 is installed on the base 7, the bracket 9 can rotate around the base 7 in the direction of the arrow in the figure, and the preheating sock tube 10 is installed on the bracket 9 Above, the direction of the preheated sock tube 10 facing the perm 3 is a plane, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com