Liquid chromatogram silica gel stationary phase and preparation method and application thereof

A liquid chromatography and stationary phase technology, applied in the field of liquid chromatography silica gel stationary phase and its preparation and use, can solve the problems of complex stationary phase preparation method, and achieve the effects of simple preparation method, good reproducibility and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

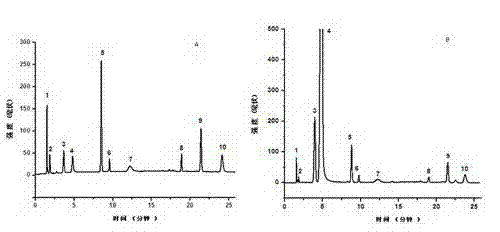

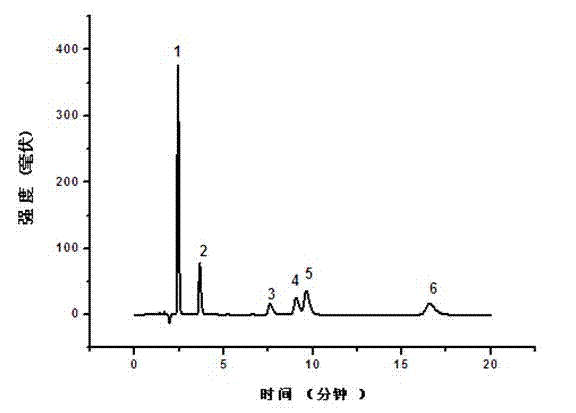

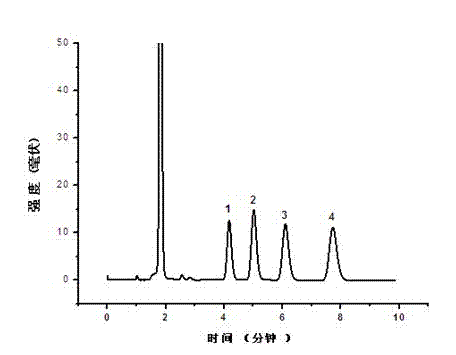

[0022] Example 1 Preparation of hydrophobic-weak anion exchange mixed mode silica gel stationary phase.

[0023] Add 2.5 g of activated silica gel to 60 ml of treated anhydrous toluene, then add 0.99 g of n-octyltriethoxysilane and 0.80 g of 3-aminopropyltriethoxysilane (total moles of silane coupling agent 0.0072, molar ratio 1:1), stirring mechanically, drop 3 drops of triethylamine. N 2 After heating under reflux for 20 h under protection, it was cooled, filtered, washed several times with toluene, methanol and acetone in turn, and dried in vacuum at 60°C for 5 h before use.

Embodiment 2

[0024] Example 2 Preparation of hydrophobic-weak anion exchange mixed mode silica gel stationary phase.

[0025] Add 2.5 g of activated silica gel to 60 ml of treated anhydrous toluene, then add 1.59 g of n-octyltriethoxysilane and 0.32 g of 3-aminopropyltriethoxysilane (total moles of silane coupling agent 0.0072, molar ratio 4:1), stirring mechanically, drop 3 drops of triethylamine. N 2 After heating under reflux for 20 h under protection, it was cooled, filtered, washed several times with toluene, methanol and acetone in turn, and dried in vacuum at 60°C for 5 h before use.

Embodiment 3

[0026] Example 3 Preparation of hydrophobic-weak anion exchange mixed mode silica gel stationary phase.

[0027] Add 2.5 g of activated silica gel to 60 ml of treated anhydrous toluene, then add 1.77 g of n-octyltriethoxysilane and 0.18 g of 3-aminopropyltriethoxysilane (total moles of silane coupling agent 0.0072, molar ratio 8:1), stirring mechanically, drop 3 drops of triethylamine. N 2 After heating under reflux for 20 h under protection, it was cooled, filtered, washed several times with toluene, methanol and acetone in turn, and dried in vacuum at 60°C for 5 h before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com