Kernel opener

A technology of outer frame and inner frame, which is applied in home appliances, applications, kitchen utensils, etc., and can solve the problems of debris flying around, incomplete nuts, and being stuck in openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

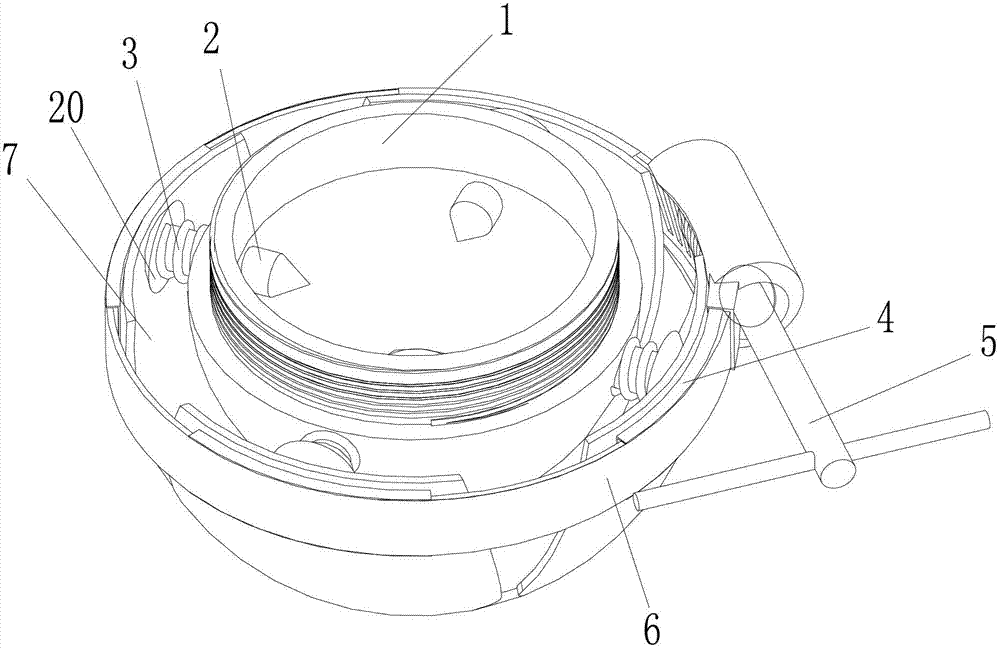

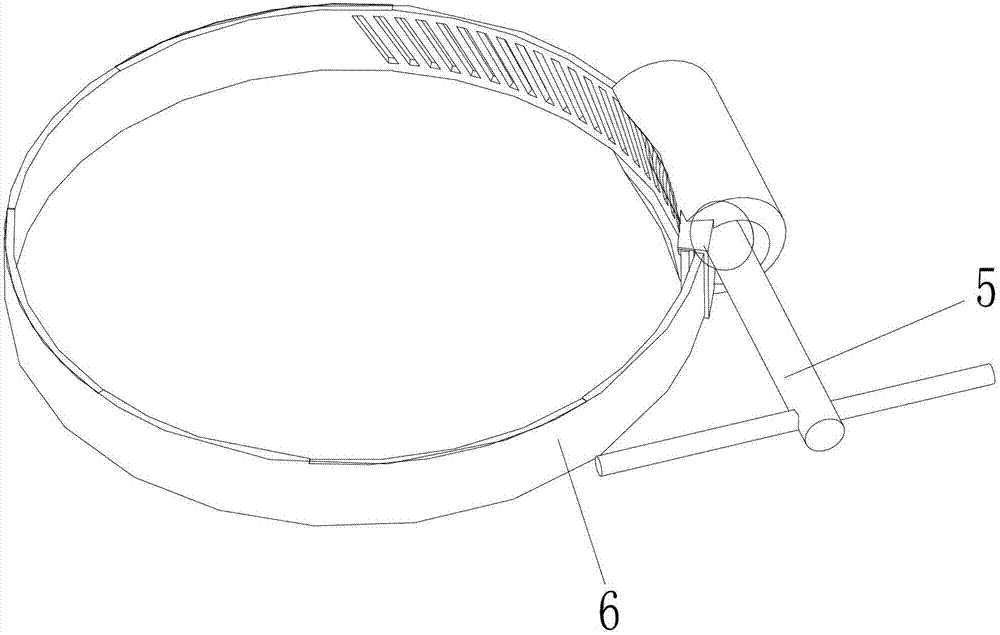

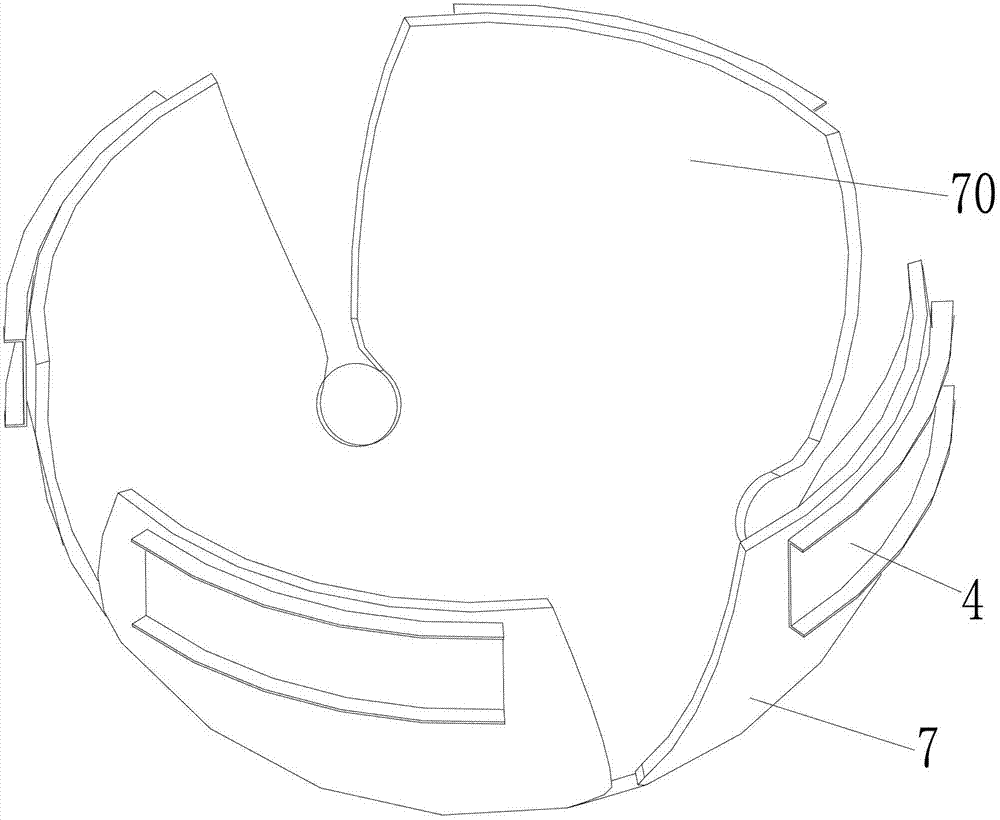

[0016] see figure 1 Shown core opener, comprises the outer frame 7 that is roughly hemispherical shell shape, is fixed in the equally roughly hemispherical shell-shaped inner frame 1 of being fixed in the cavity of outer frame 7; Described outer frame 7 is not complete hemispherical shell, and It includes a plurality of non-contact cantilevers 70 protruding outward from its middle position; the through hole 10 provided on the inner frame 1 slides the nail 2 set in the through hole 10, and the nail 2 The inner side is inserted into the inner frame 1, and the outer side is against the cantilever 70; the guide groove 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com