Tail abandoned-material processing equipment of automatic glue-cable cutter

A processing equipment and cutting machine technology, applied in metal processing and other directions, can solve the problems of high labor cost and low efficiency, and achieve the effect of reducing labor cost and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

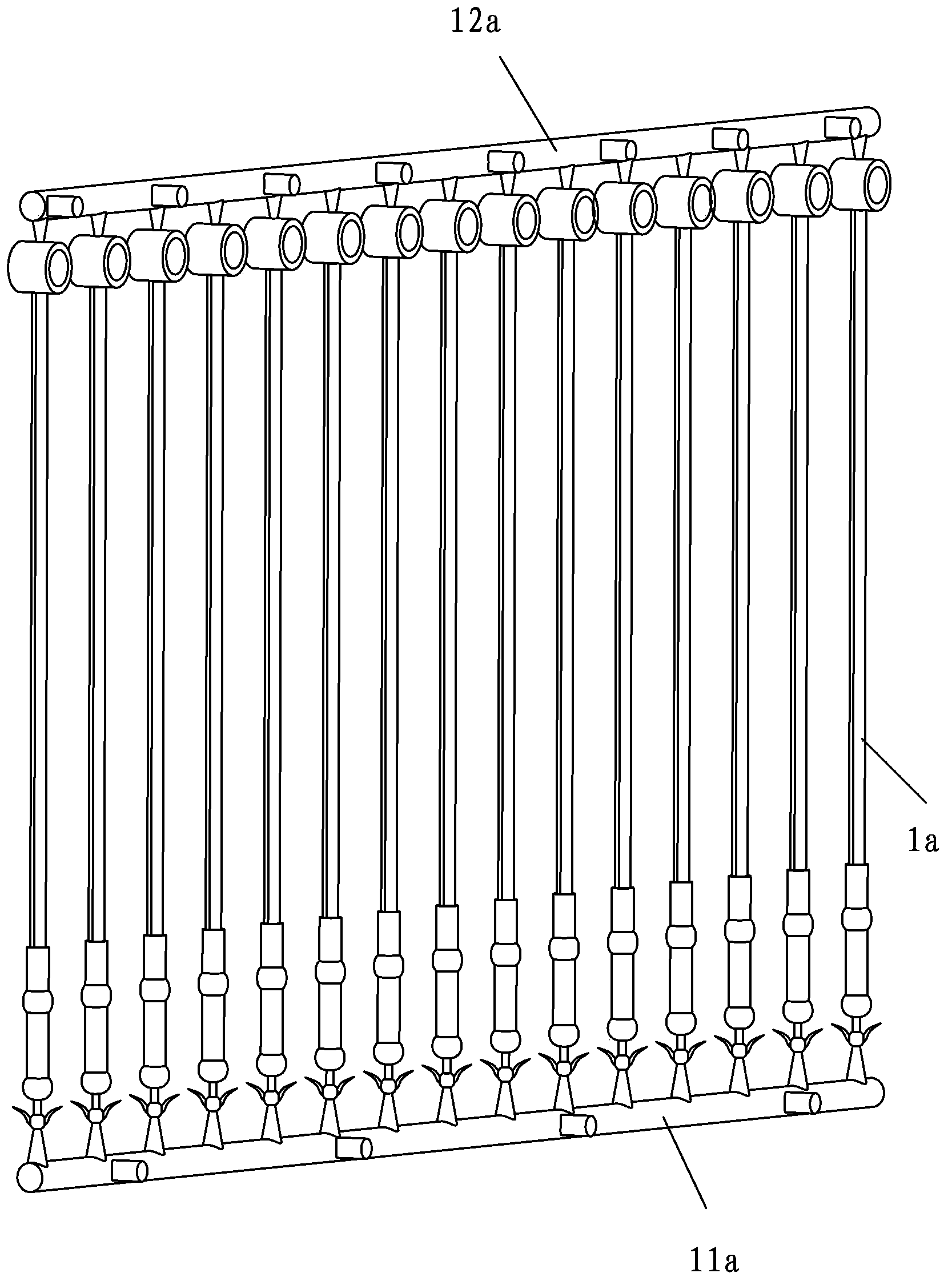

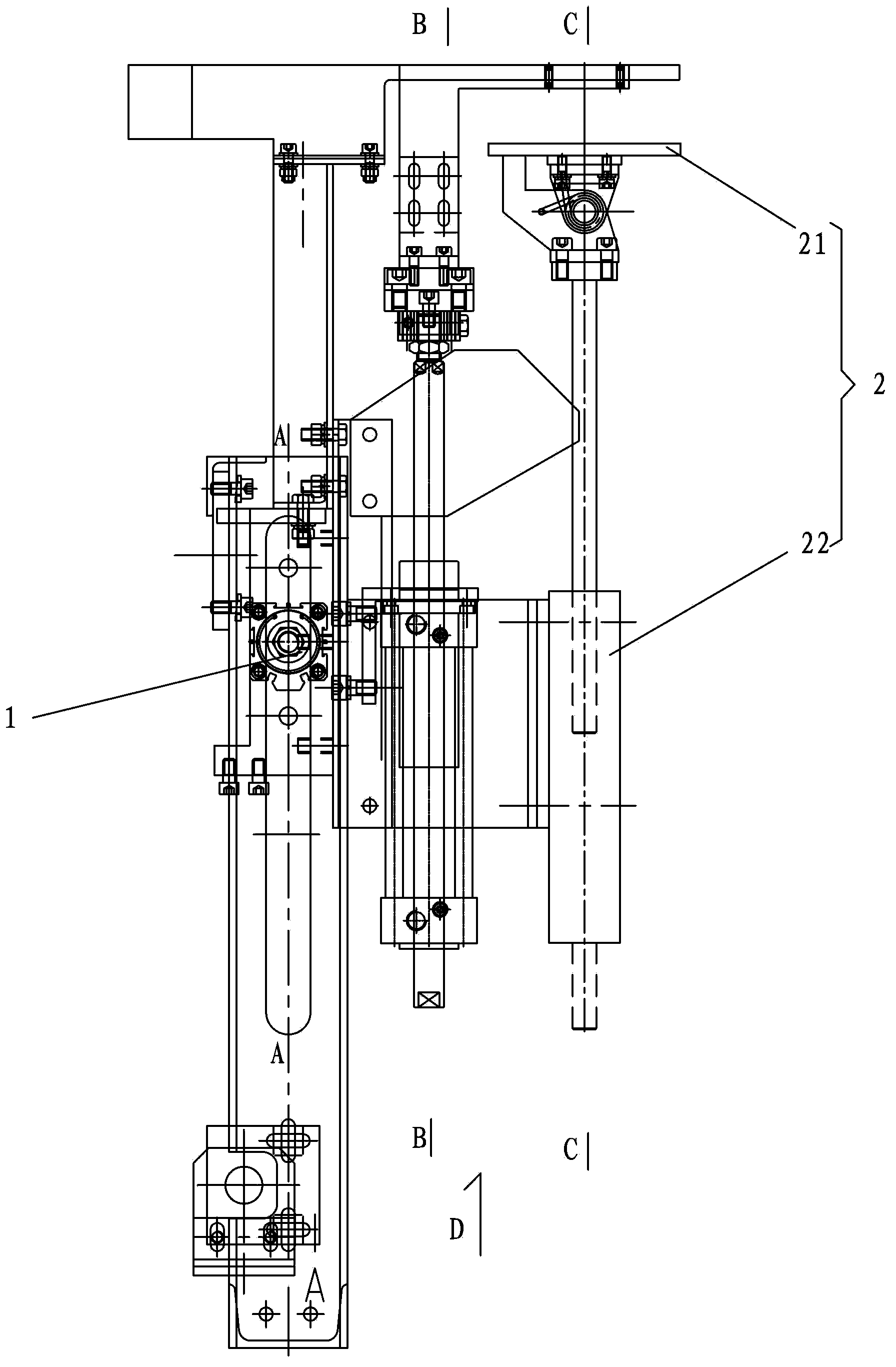

[0037] Such as Figures 2 to 7 As shown, the tail waste processing equipment of the rubber cable automatic cutting machine of the present invention includes a breaking device 1 , a tail waste collection device 2 and a height adjustment device 3 .

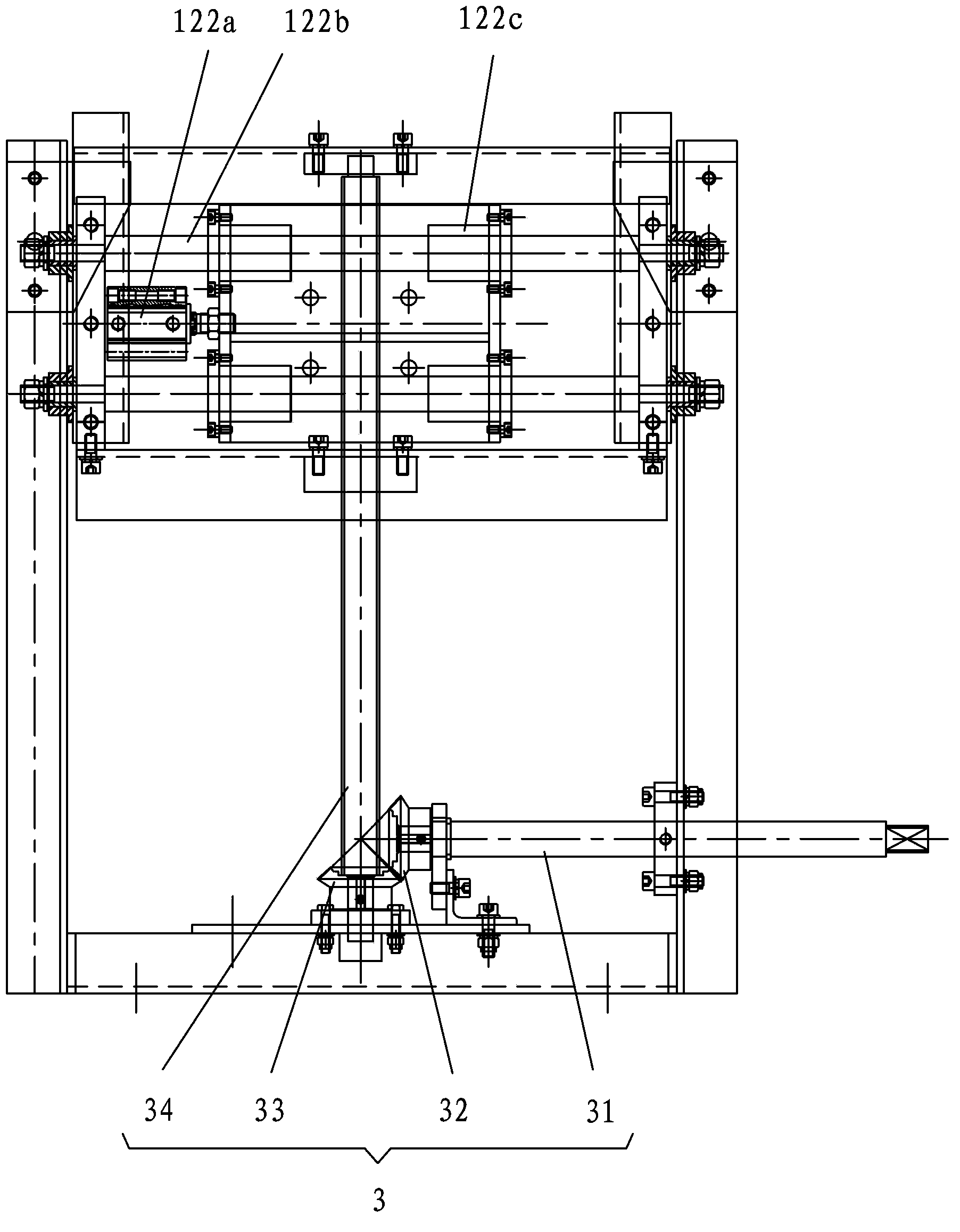

[0038] The breaking device 1 includes a plurality of rod frames 10, a plurality of pull rods 11 and a breaking driving mechanism 12; the breaking driving mechanism 12 includes a lifting gas 121a, a lifting guide rod 121b, a lifting guide sleeve 121c, a translation cylinder 122a, and a translation guide rod 122b and translation guide sleeve 122c. The lifting cylinder 121a and the lifting guide rod 121b are arranged vertically, the lifting guide rod 121b is matched with the lifting guide sleeve 121c, the translation cylinder 122a and the translation guide rod 122b are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com