Fiber Connector Components

A technology of optical fiber connecting components and connecting parts, which is applied in the direction of coupling of optical waveguides, etc., can solve the problems that the USB female interface cannot be accurately aligned, easy to hit, and the positioning feet are damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

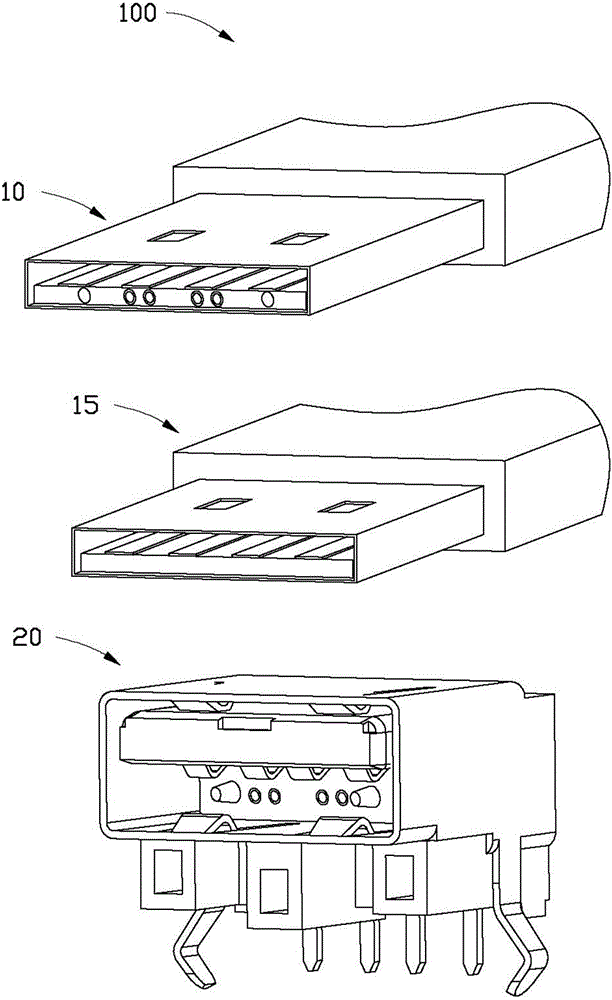

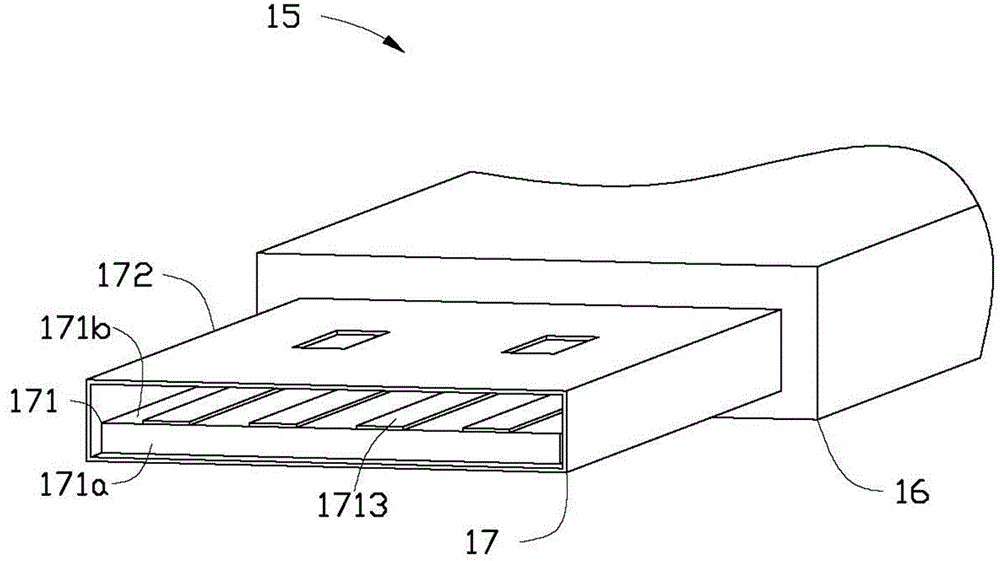

[0016] see figure 1 , is the fiber optic connection assembly 100 according to the first embodiment of the present invention, which includes a first male interface 10 , a second male interface 15 and a female interface 20 connected to the first male interface 10 or the second male interface 15 .

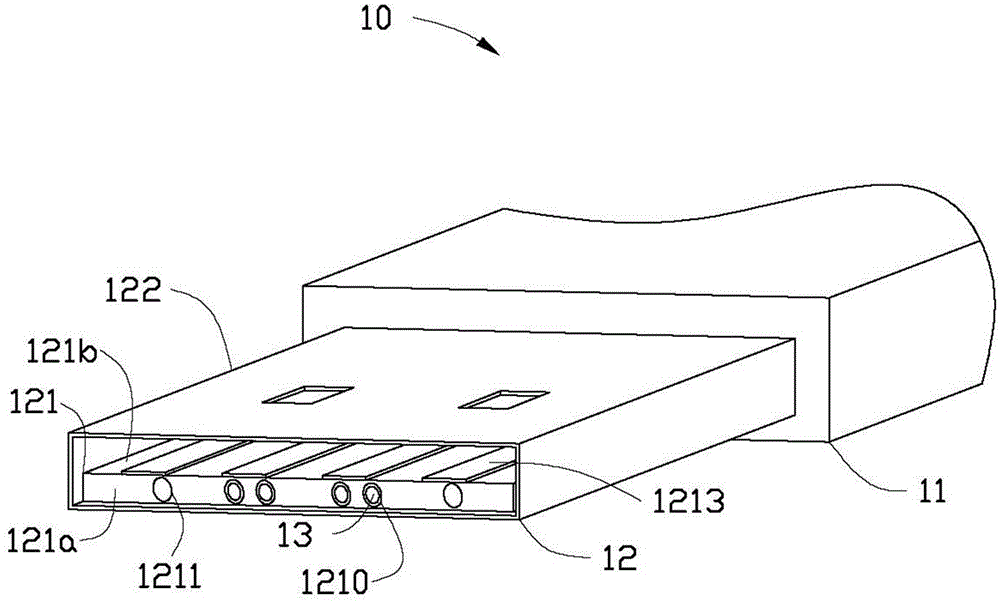

[0017] see figure 2 , the first male interface 10 includes a first gripping portion 11 and a first connecting portion 12 disposed on the first gripping portion 11 . The first connecting portion 12 includes a hollow first surrounding portion 122 and a first flat plate 121 disposed in the first surrounding portion 122 . The first flat plate 121 includes a first end surface 121 a away from the first gripping portion 11 . The first end surface 121a is provided with a plurality of first receiving holes 1210 for receiving the first optical fiber interface 13 . The first end surface 121a is also provided with a plurality of positioning holes 1211 . The distance from the first end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com