Plastic large plane bending regulation device of plastic

A technology of adjusting device and large surface, applied in the field of plastic large surface bending adjustment device, can solve problems such as insufficient straightness of the profile, influence on the physical properties of the profile, influence on the apparent quality of the profile, etc., to achieve the effect of ensuring the plane quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

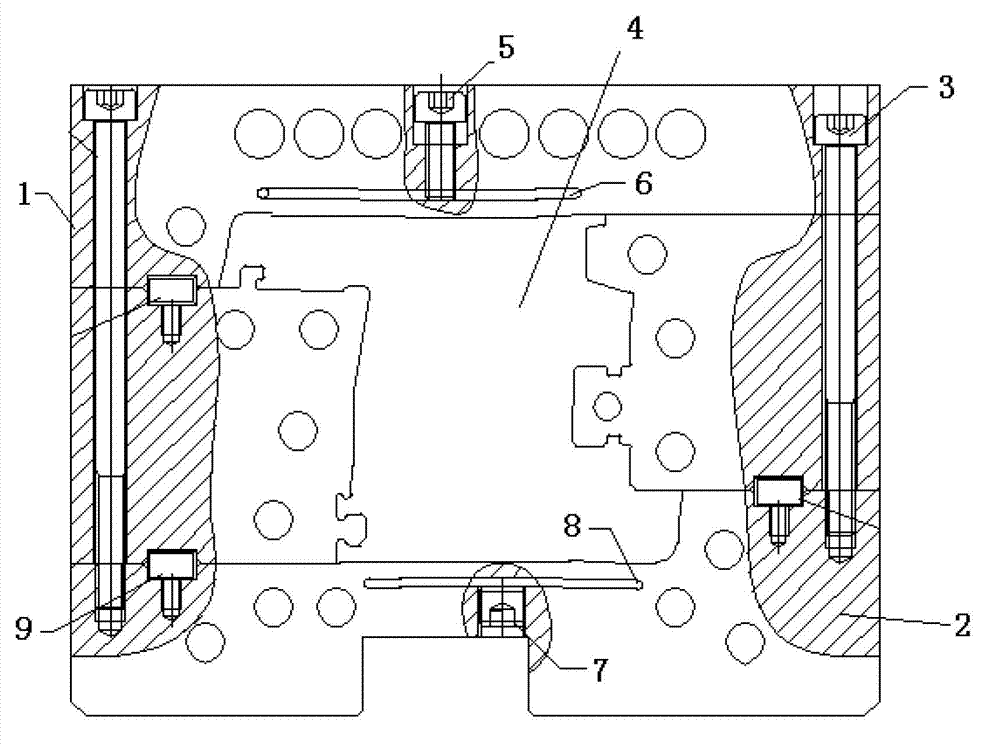

[0009] Referring to the drawings, a plastic large-surface bending adjustment device includes upper and lower sizing blocks 1, 2. The upper and lower sizing blocks 1, 2 are connected together by connecting screws 3, the upper and lower sizing blocks A shaping cavity 4 is provided between 1 and 2, the middle of the upper shaping block 1 is equipped with an anti-warpage adjustment screw 5, and the lower end of the anti-warpage adjustment screw 5 is connected to the upper adjustment wire slot 6, and the lower An anti-warpage amount screw plug 7 is installed on the shaping block 2. The upper end of the anti-warpage amount screw plug 7 rests on the lower adjusting wire seam 8. A positioning key 9 is provided between the upper and lower shaping blocks 1 and 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com