Grinding machine for ultra-precision machining of needle valve body end face of high-pressure common rail injector

An ultra-precision machining, high-pressure common rail technology, used in grinding machines, metal processing equipment, machine tools suitable for grinding workpiece planes, etc. The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

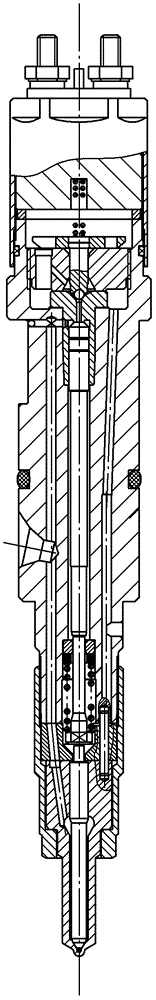

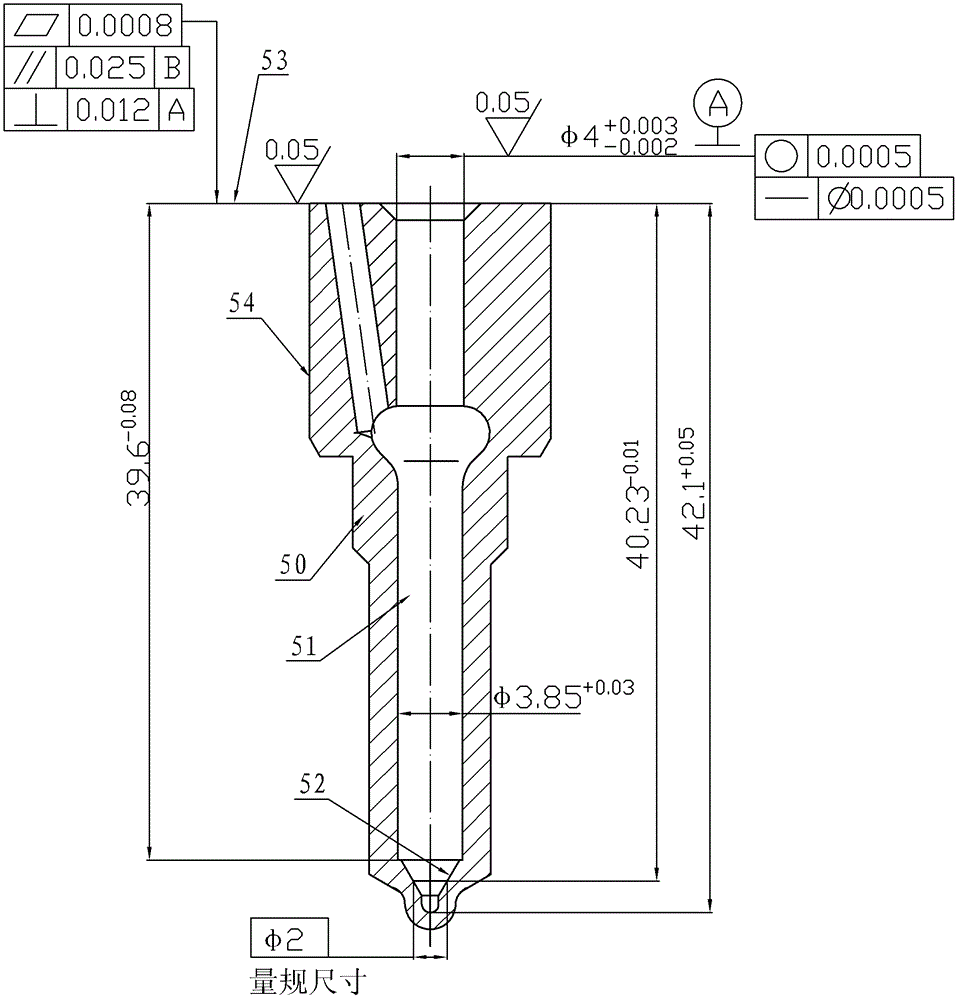

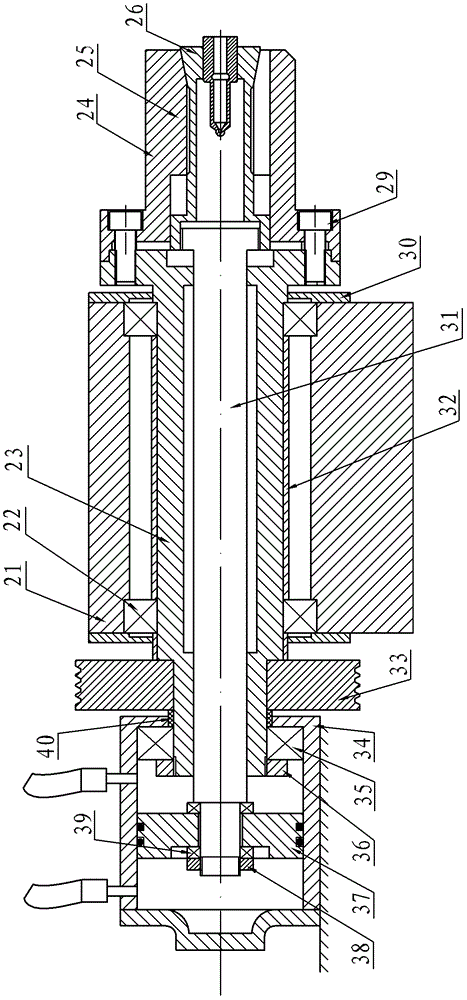

[0031] A grinding machine for ultra-precision machining of the end face of the needle valve body of a high-pressure common rail injector, such as Figure 4 , Figure 5 As shown, it includes bed 1, needle valve body precision positioning clamping device 2, workpiece motor 3, pneumatic pushing device 4, fine grinding frequency conversion electric spindle 5, super fine grinding frequency conversion electric spindle 6, longitudinal slide table 7, horizontal slide table Table 8, longitudinal servo motor 9 and horizontal servo motor 10, the needle valve body precise positioning clamping device 2 is fixedly installed on the bed 1, the horizontal sliding table 8 is set on the bed 1, and the two are matched by linear guide rails. The linear sliding of the horizontal sliding table 8 relative to the bed 1 is realized through the screw nut mechanism between the horizontal sliding table 8 and the bed 1; the vertical sliding table 7 is fixed on the horizontal sliding table 8, and the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com