Fluttering winter jujube sorter with inclined discharge pipe

A leaky tube and winter jujube technology, applied in the field of agricultural automation equipment, can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

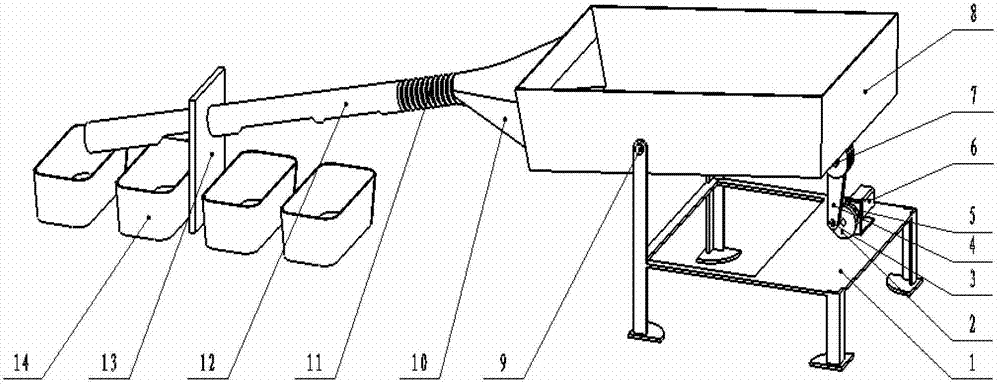

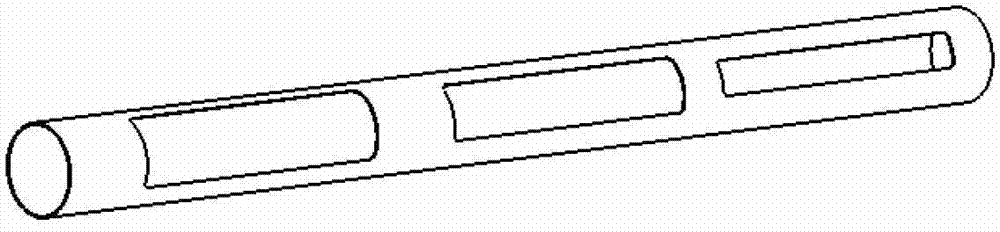

[0008] The fluctuating inclined leak tube type winter jujube size selector is composed of a bracket 1, a flywheel 2, an eccentric shaft 3, a connecting rod 4, a reducer 5, a motor 6, a rotating shaft 7, a jujube storage box 8, a short shaft 9, an inclined funnel 10, and a corrugated Tube 11, drain tube 12, support block 13, and sorting box 14 are characterized in that: the bracket 1 is placed on the ground, the motor 6 is installed on the bracket 1, the motor 6 is connected with the flywheel 2 through the reducer 5, and the eccentric shaft 3 is installed on the flywheel 2, the eccentric shaft 3 is equipped with a link 4, the link 4 is installed on the ear plate of the jujube storage box 8 through the rotating shaft 7, and the jujube storage box 8 is also installed on the support 1 through the short shaft 9, and the oblique The funnel 10 is installed on the front end of the date storage box 8, the bellows 11 is installed on the front end of the inclined funnel 10, the drain pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com