Grading packaging machine of integrated sorting machine for potatoes and other underground tuber crops

A technology for underground tubers and potatoes, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of inaccuracy, high production costs, sorting of potato size and grade, etc., so as to improve work efficiency and avoid uneven quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail based on the drawings and specific embodiments.

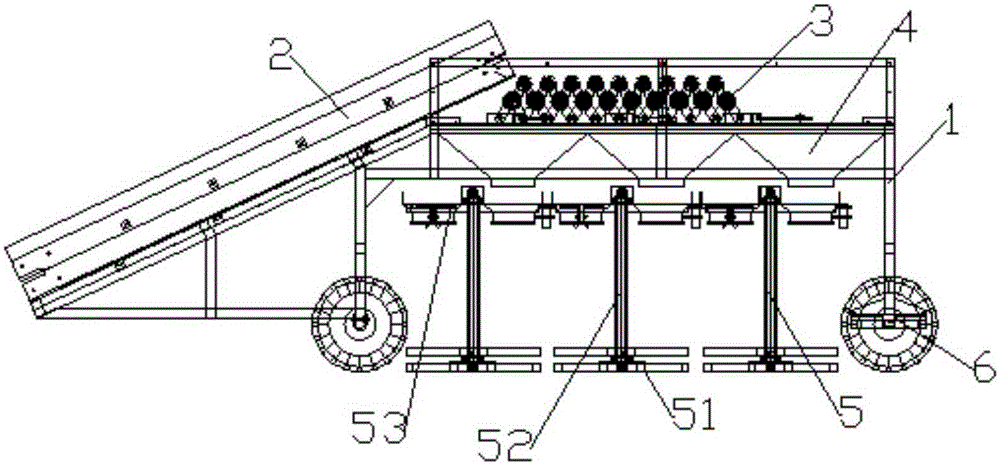

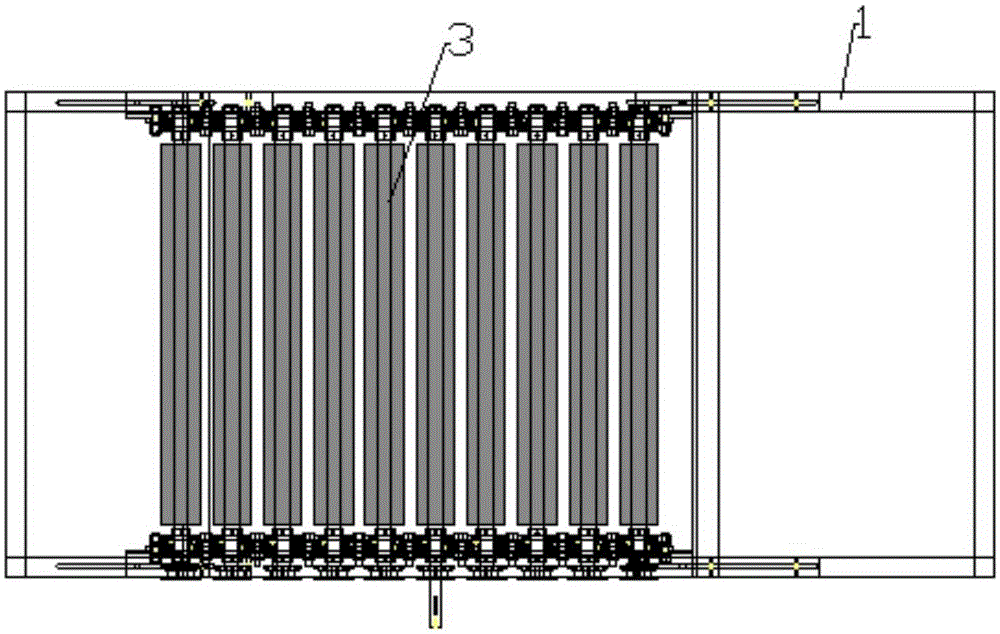

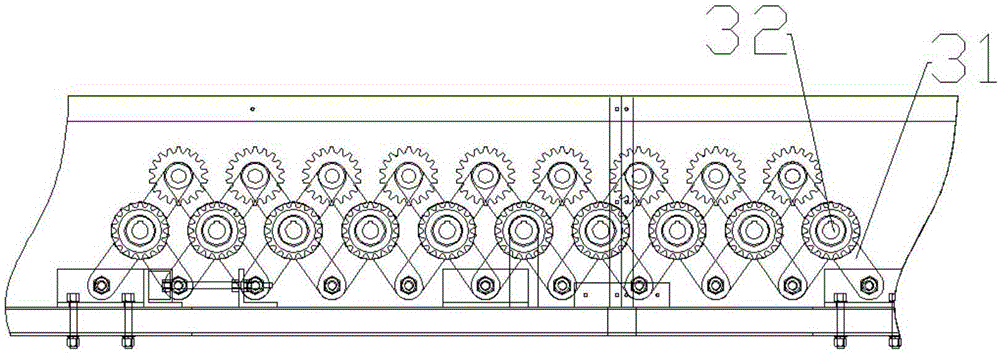

[0026] Such as figure 1 As shown, the present invention includes a grading packaging frame 1, an inclination belt 2, a grading machine 3, a silo 4, a packaging turntable 5, a packaging bag and a wheel assembly 6.

[0027] Such as Figure 4 As shown, the inclination belt 2 is placed obliquely, the bottom end of which is the inlet and the top end is the outlet, and the upper surface of the inclination belt 2 is evenly provided with a plurality of V-shaped rubber baffles 21 to avoid round materials Scroll down.

[0028] The inclination belt 2 is 650mm wide, including the inclination belt mounting plate, the inclination belt drive roller, the inclination belt reversing roller and the inclination conveyor belt. The inclination belt 2 is fixedly installed on the grading packaging rack 1 through the inclination belt mounting plate, and the inclination belt mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com