Fin and base punching combination method of radiator

A combination method and technology of heat dissipation fins, applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems affecting the plastic deformation of the clamp rib 95, poor clamping, easy breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Relevant present invention is to achieve above-mentioned purpose, adopts technical means and effect thereof, enumerates feasible embodiment hereby, and cooperates accompanying drawing to illustrate as follows:

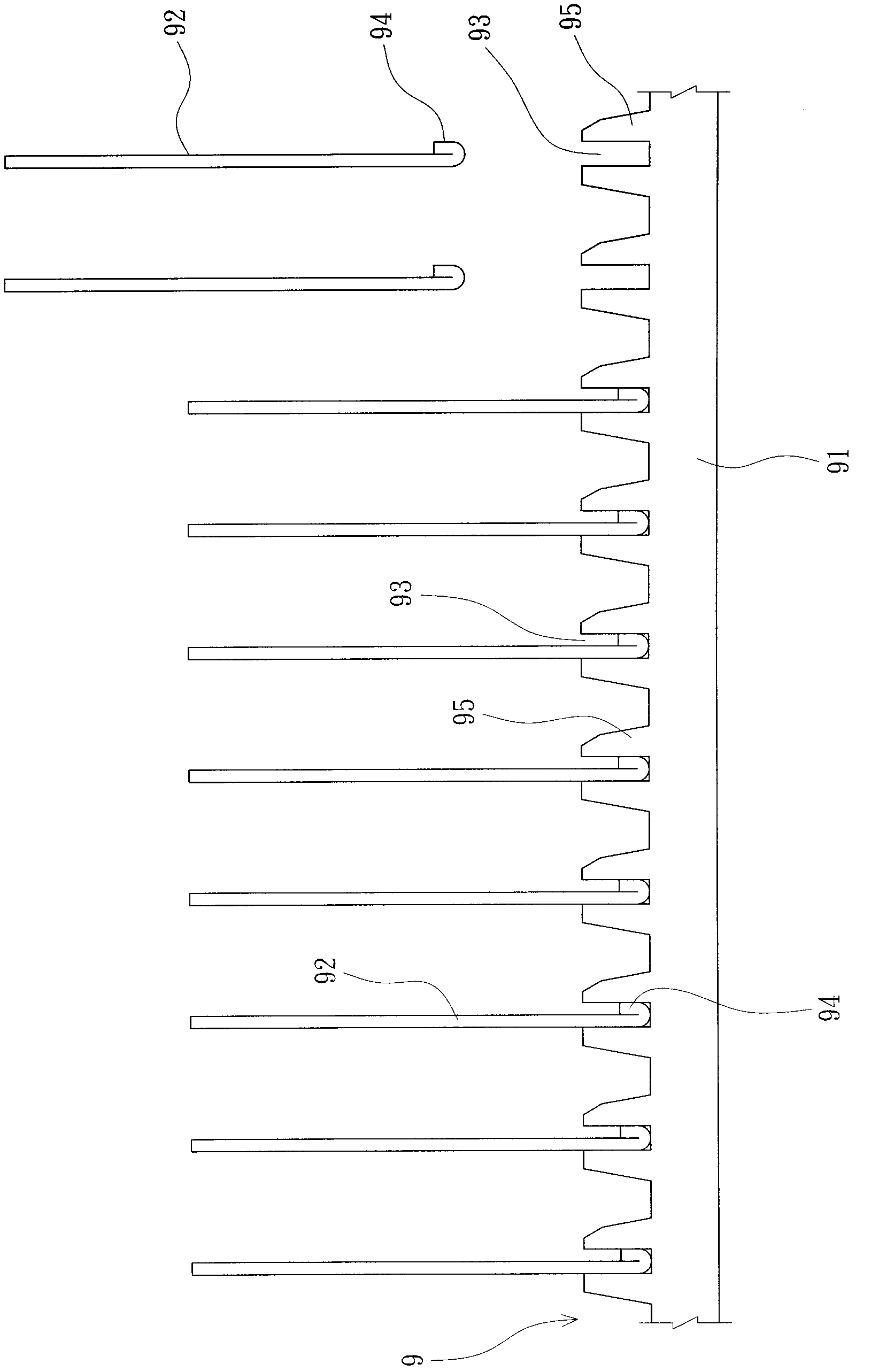

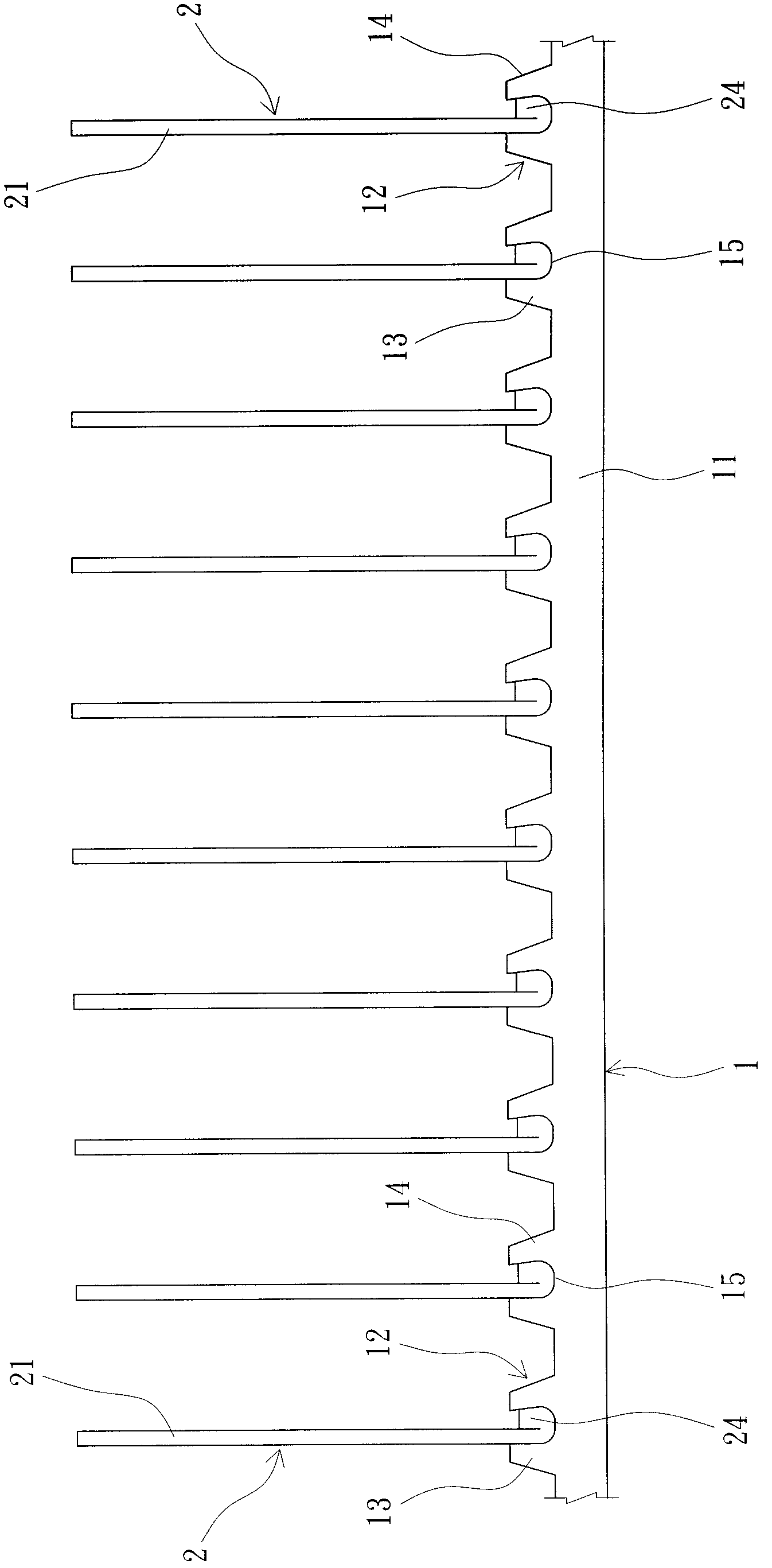

[0037] First, see image 3 , the heat sink of the present invention mainly assists the heat source of the electronic device to dissipate heat. As shown in the figure, the heat sink is inserted with a plurality of heat dissipation fins 2 arranged at equal intervals on a base 1, and then for each heat dissipation fin Sheet 2 is fixed by stamping combination.

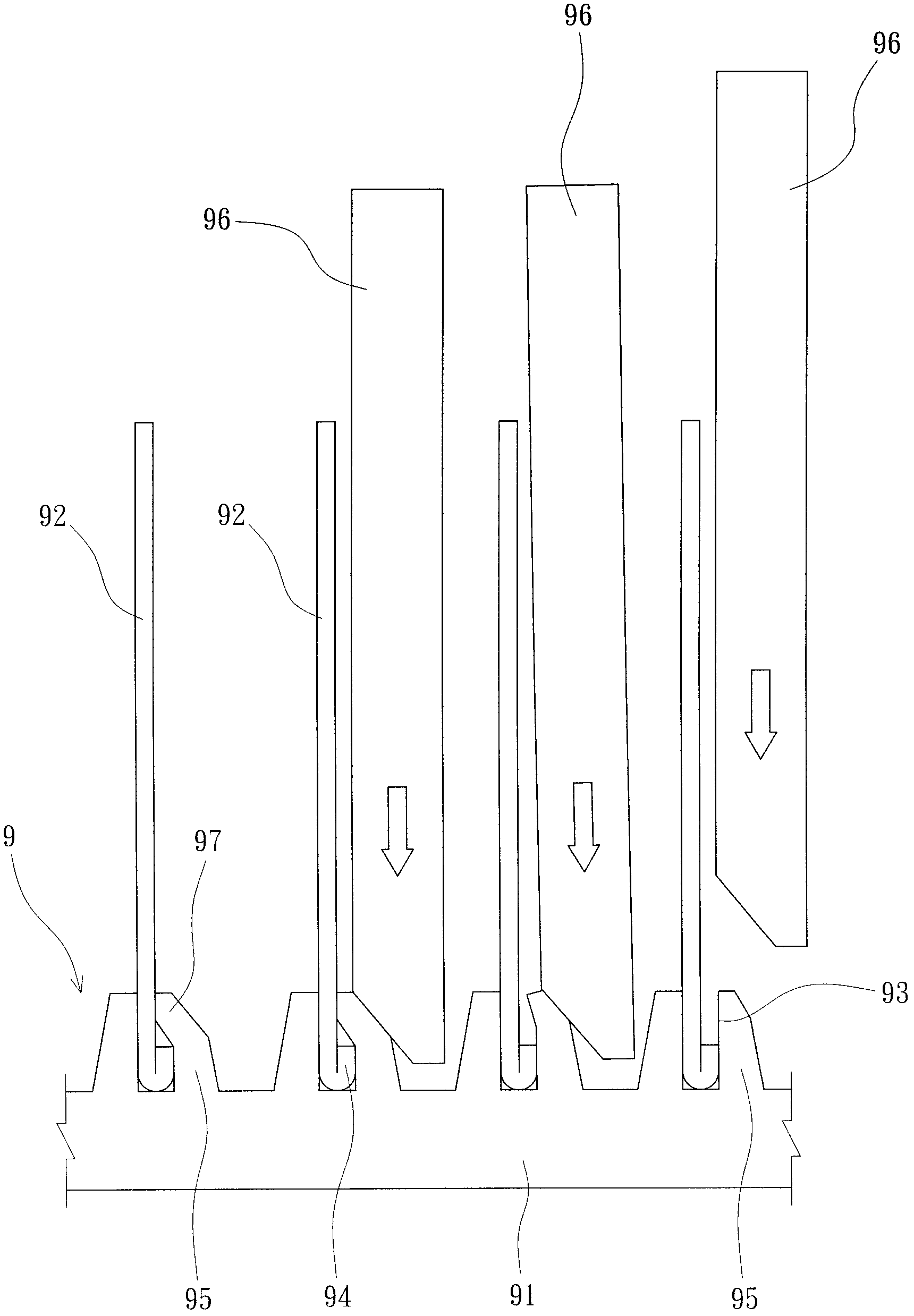

[0038] exist image 3 , Figure 4 and Figure 5 In the preferred embodiment shown, the present invention is mainly aimed at the stamping combination method of the cooling fins 2 and the base 1 of the radiator. A plurality of positioning portions 12 are arranged at intervals, and each positioning portion 12 includes a first protruding rib 13 and an opposite second protruding rib 14 , and a positioning gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com