Slicing machine for clamping pieces

A slicer and clamping technology, which is applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of high processing efficiency, low processing accuracy, troublesome operation, etc., and achieve the effect of high processing efficiency and guaranteed processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

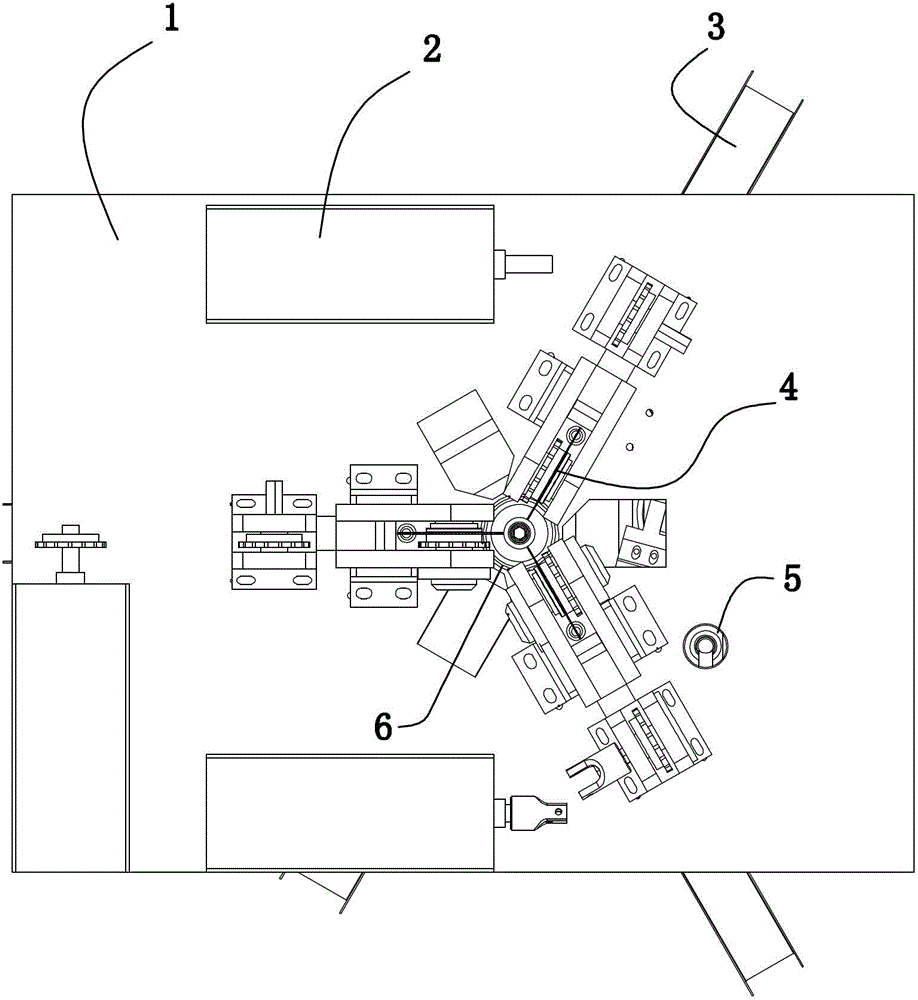

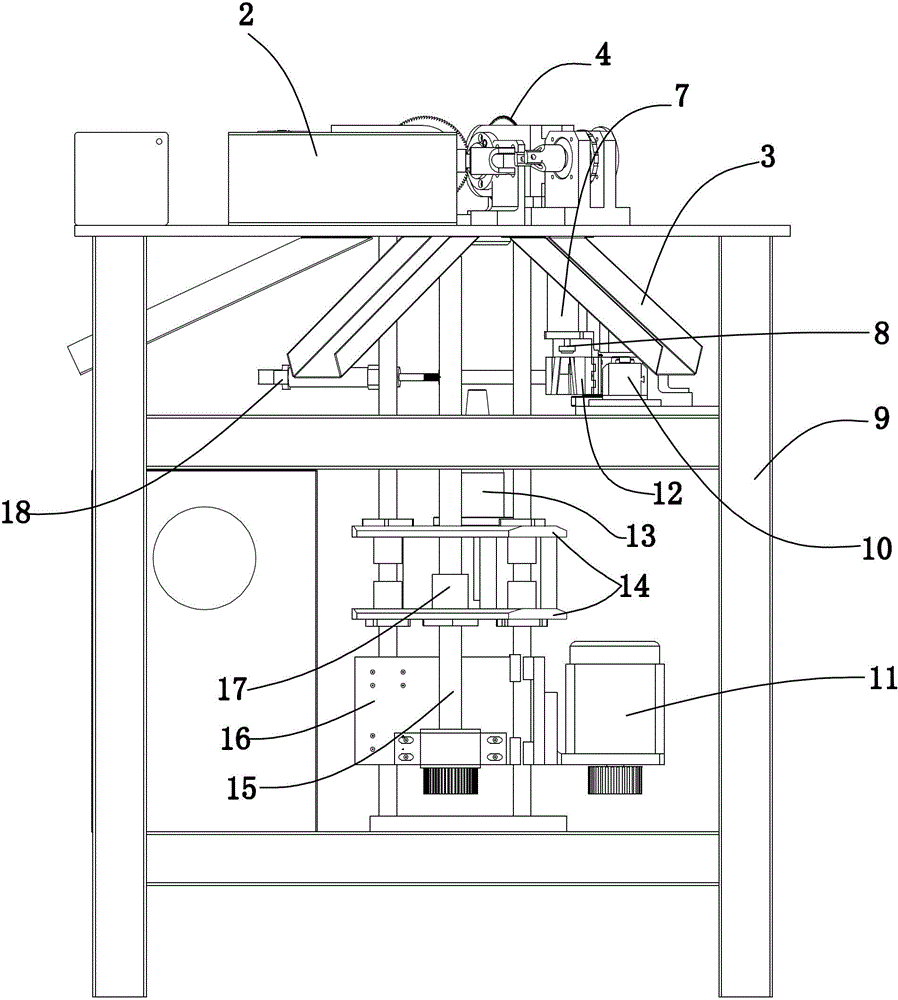

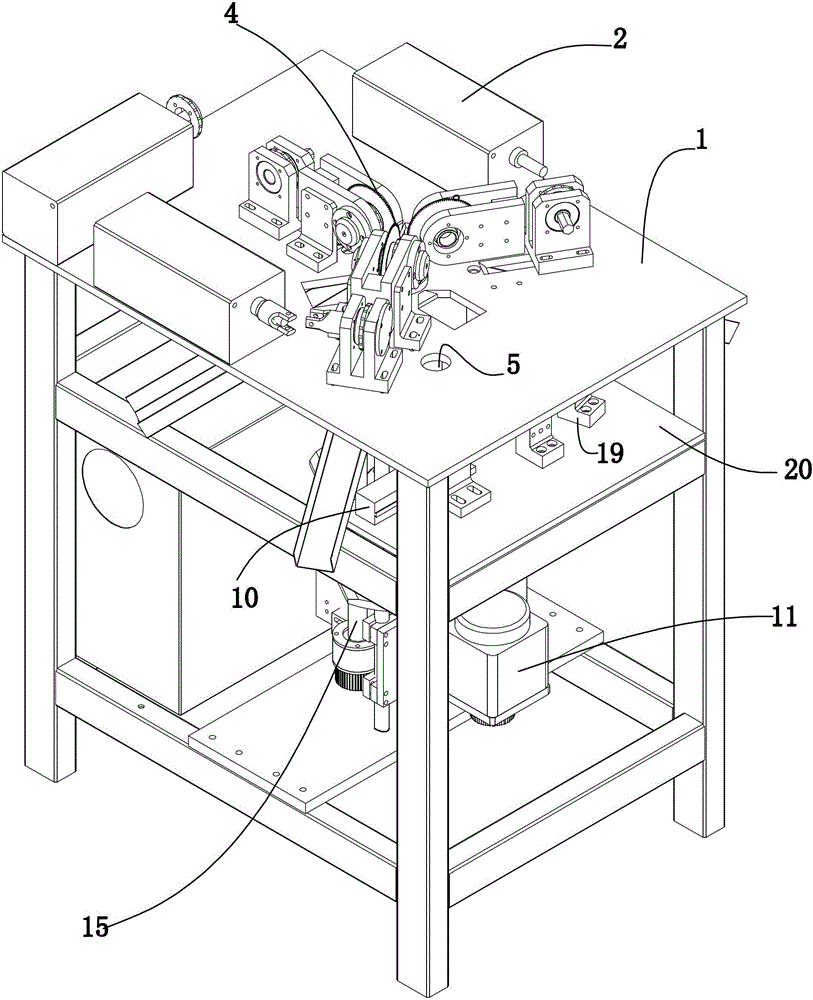

[0028] Embodiment: a kind of sandwich slicer (referring to attached figure 1 attached figure 2 attached image 3 ), including a frame 9, a driving mechanism arranged on the frame and a processing mechanism fixed on the frame, the processing mechanism includes a processing tool 4 and a power transmission mechanism 2 connected with the processing tool. The driving mechanism includes a feeding mechanism, a clamping mechanism and a material shifting mechanism. Frame 9 is connected by square tube and is square frame structure, and frame top is fixed with workbench 1, and frame bottom is fixed with base plate 21, and vertically fixed plate 16 is fixed on the base plate, and frame middle part is fixed with shelf 20.

[0029] The middle of the workbench is provided with a circular hole 6, and the machining tool is three pairs, which are fixed on the workbench around the circular hole symmetrically at intervals of 120°. The machining tool includes a cutting blade whose cutting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com