Inflating nozzle device

A technology of inflatable nozzles and air holes, applied in the direction of valve devices, valve operation/release devices, valve details, etc., can solve the problem of air pressure reduction of inflatable parts, and achieve the effect of improving a large amount of deflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

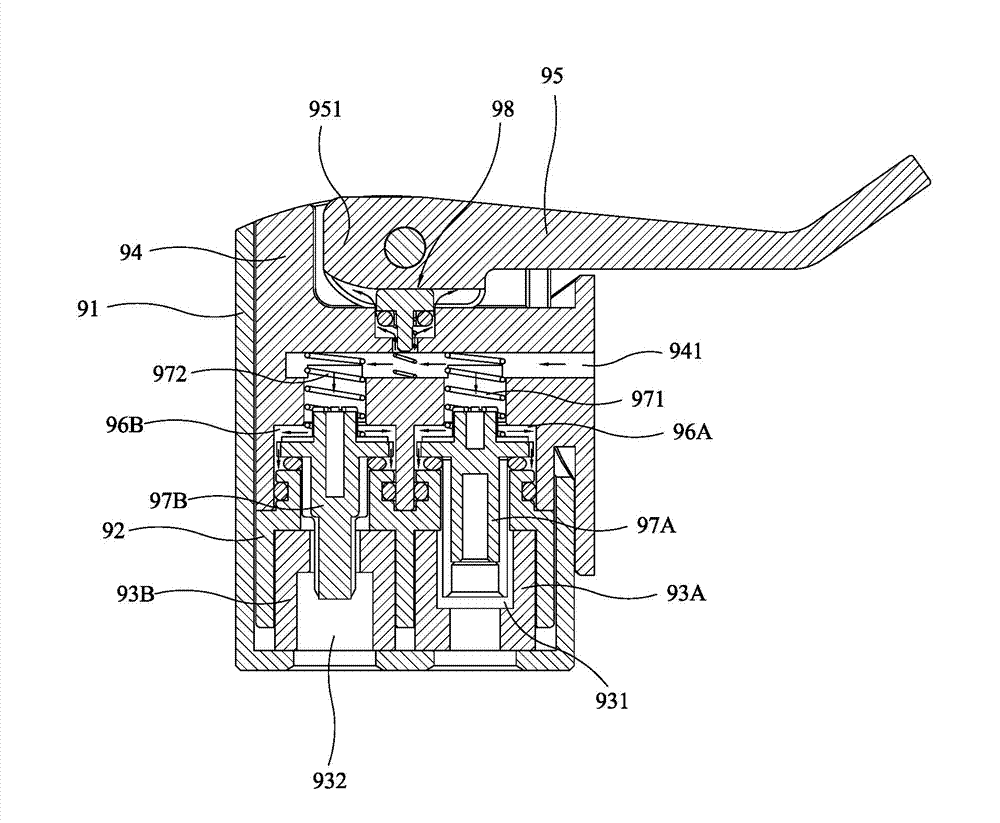

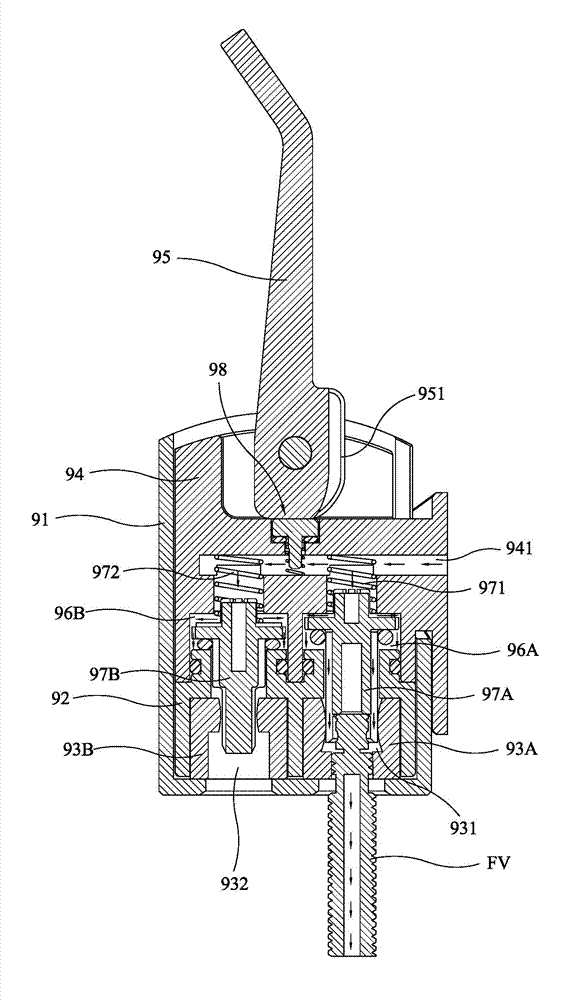

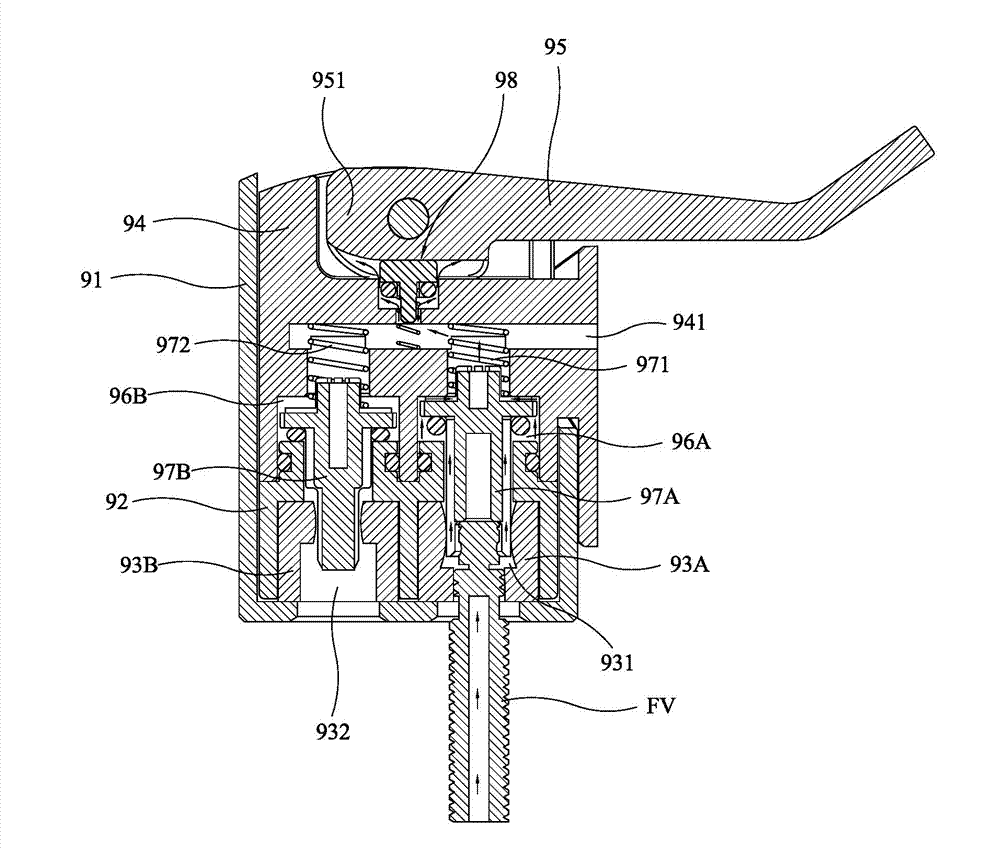

[0073] Please refer to figure 2 , image 3 and Figure 4A , the present invention includes:

[0074] A head seat 10, which extends upwards around a bottom plate 11 with a trunk portion 12 for defining an upwardly transparent assembly chamber 13 inside, the bottom plate 11 is longitudinally provided with a first air hole 11A connecting the inside and outside of the assembly chamber 13, and a second Air hole 11B, a tip hole 14 runs through the opposite sides of the top edge of the head seat 10 transversely, and a gap 15 is recessed at the rear end, and a sleeve 16 with a sleeve hole is externally connected to the trunk portion 12 under the gap 15, and the trunk portion 12 is also provided with an air hole 17 that runs through the assembly chamber 13 within the range of the sleeve hole of the sleeve 16, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com