Engine Connecting Rod Small Head Hole Honing Fixture

A technology of engine connecting rod and small end hole, which is used in honing machine tools, manufacturing tools, grinding workpiece supports, etc. The problem of axial twist of the small end hole of the rod can overcome the problem of honing into a flared hole or an eccentric hole and reduce the axial twist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

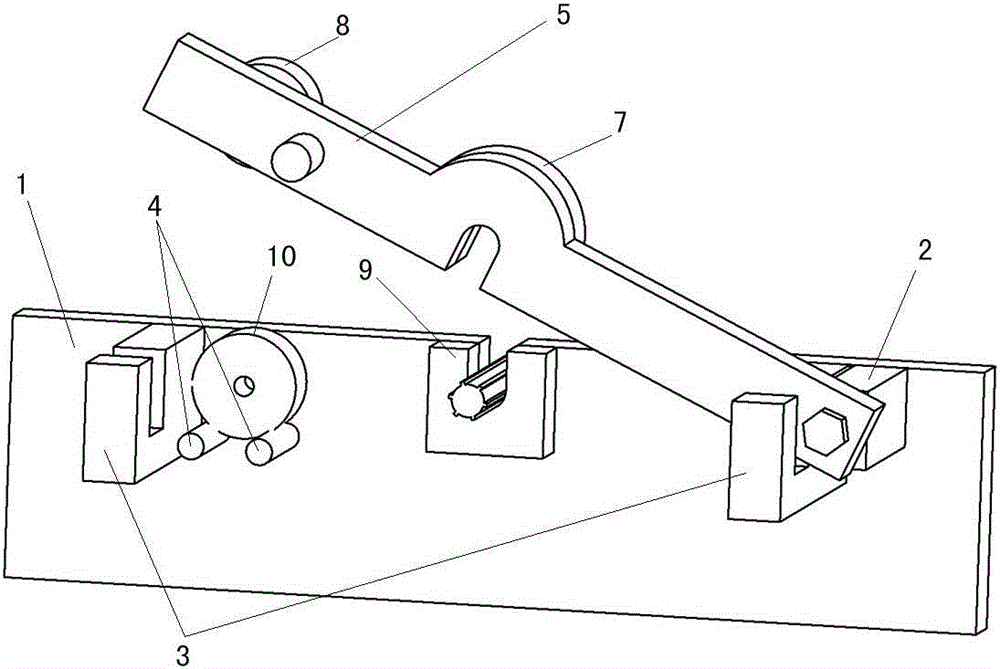

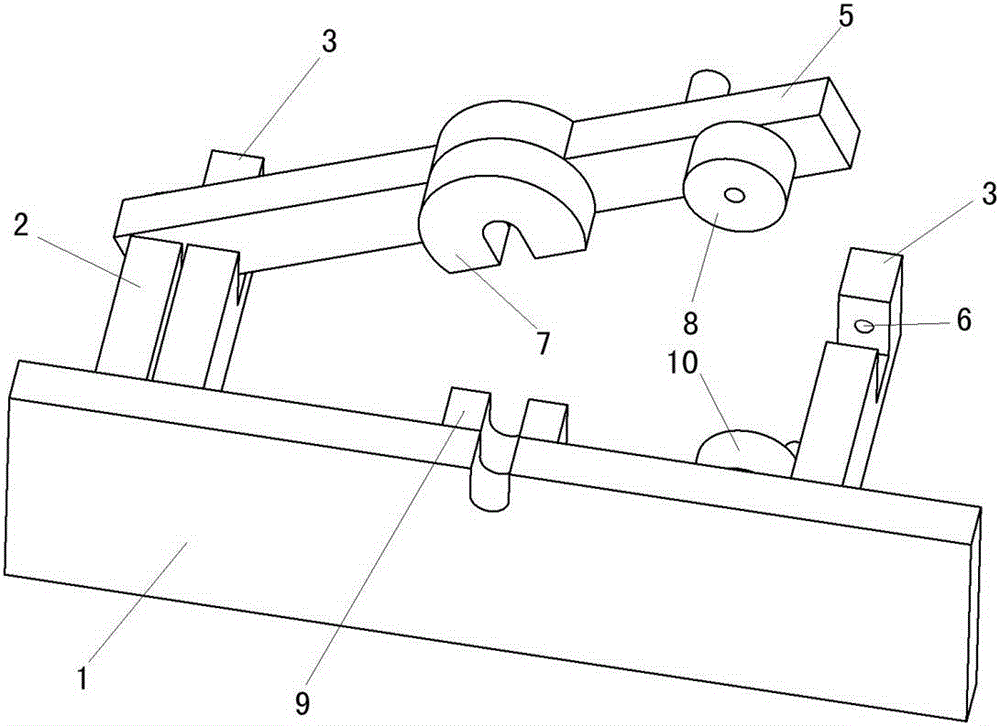

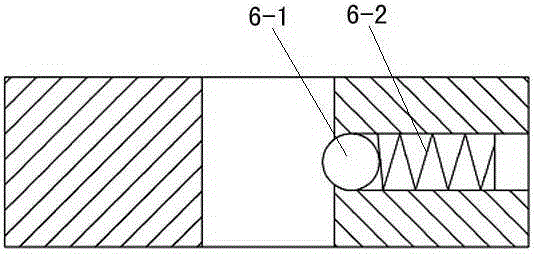

[0012] Attached figure 1 It is a front three-dimensional schematic diagram of the honing fixture for the small-end hole of the engine connecting rod of the present invention, attached figure 2 It is a reversed three-dimensional schematic diagram of the honing fixture for the small end hole of the engine connecting rod of the present invention. In the figure, 1 is the base plate, 2 is the cover support column, 3 is the limit plate, 4 is the big end support column, 5 is the cover plate, and 6 is the steel For the ball buffer mechanism, 7 and 9 are connecting rod small end positioning plates, 8 and 10 are connecting rod large end positioning plates, 6-1 is a steel ball, and 6-2 is a spring. It can be seen from the figure that the small end hole honing fixture of the engine connecting rod of the present invention includes a base plate 1, a cover plate support column 2, a limit plate 3, a large end support column 4 and a cover plate 5; a U-shaped groove is provided in the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com