Safety limiting device used for push-pull window

A technology of limit device and sliding window, applied in electric alarm locks, building locks, buildings, etc., can solve problems such as hidden safety hazards and thieves entering the room.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

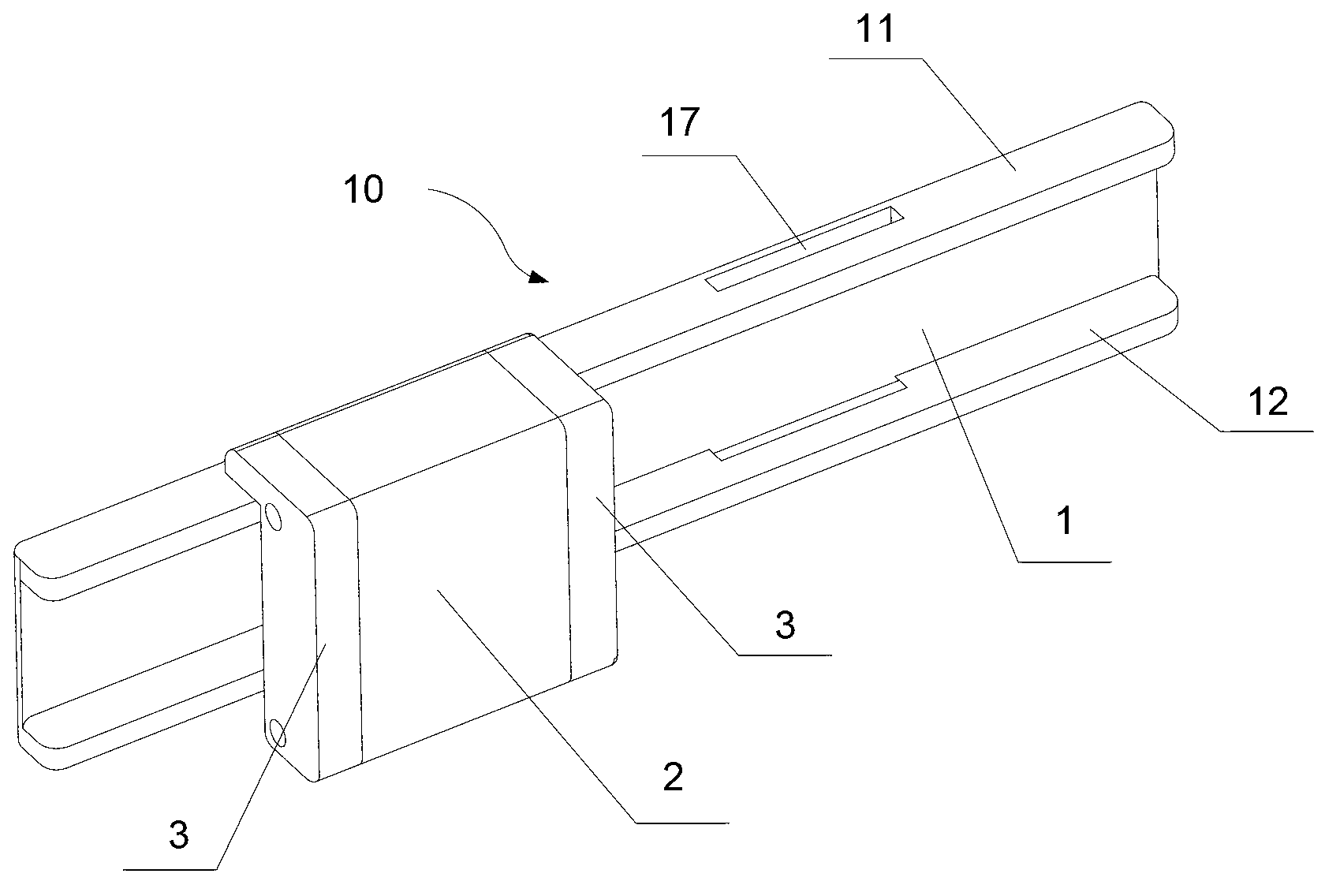

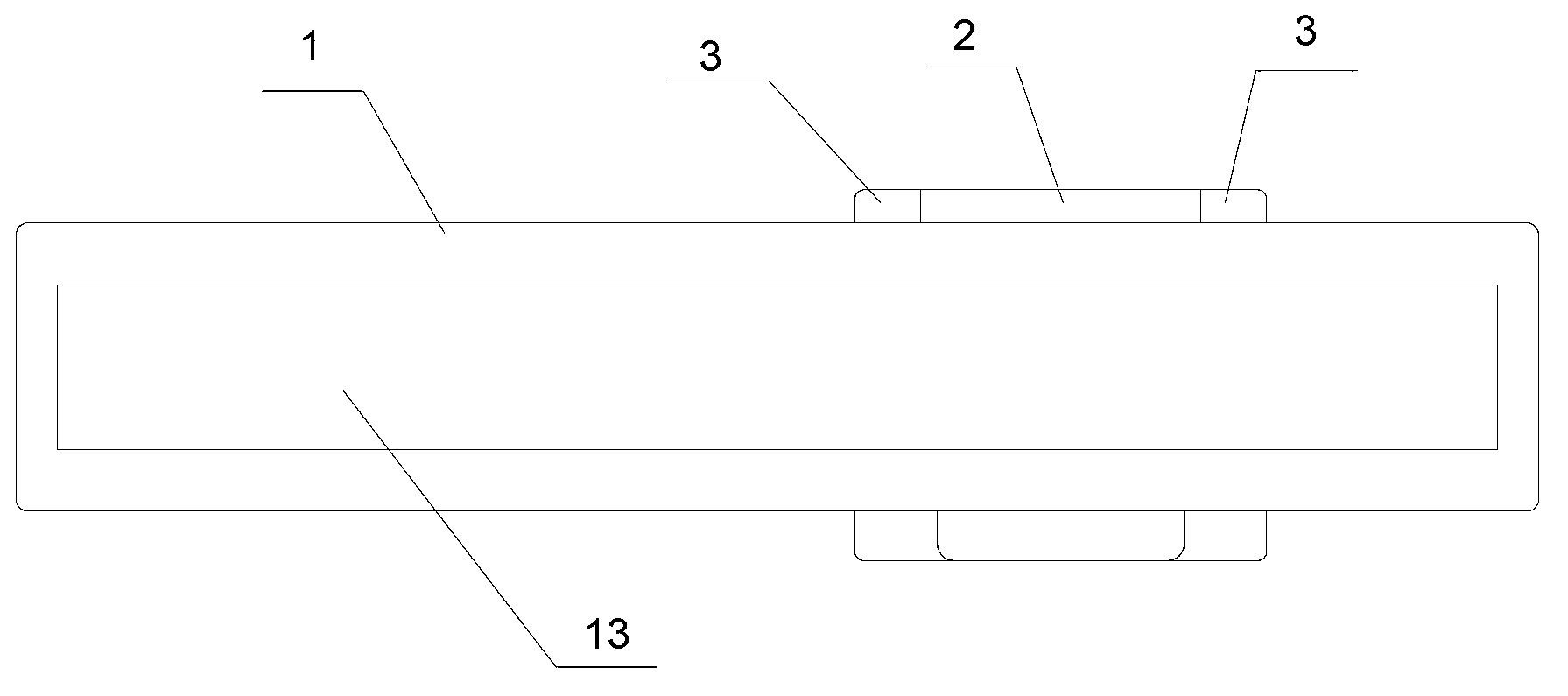

[0035] Figure 1-Figure 4 It shows the structure of the safety limit device for sliding windows according to Embodiment 1 of the present invention, Figure 5 It shows the situation of installing the safety limit device for sliding windows of the first embodiment on the sliding windows.

[0036] Wherein, the sliding window 500 includes relative inner glass 501 and outer glass 502, which is the same as the structure of the prior art, as Figure 1-Figure 5 As shown, the safety limit device 10 for sliding windows in this embodiment includes a support plate 1 attached to the inner side of the outer glass 502 by bonding or suction cup absorption, and a limit stop fixed on the support plate 1 2; wherein, the thickness of the support plate 1 is less than the gap between the inner glass 501 and the outer glass 502, the sum of the thicknesses of the support plate 1 and the stopper 2 is greater than the gap between the inner glass 501 and the outer glass 502, like this, Such as Figur...

Embodiment 2

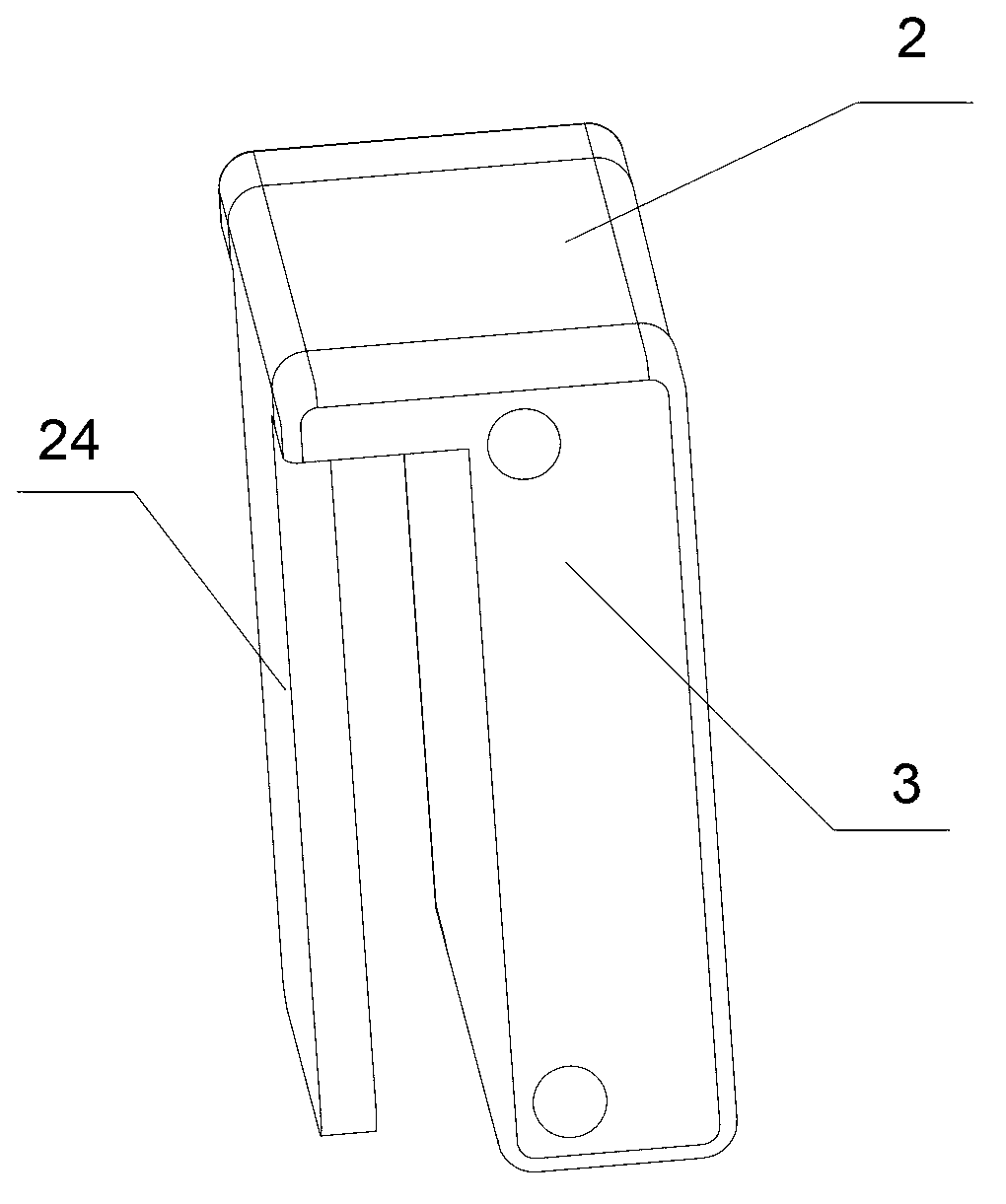

[0045] Such as Figure 6-Figure 9 As shown, the main difference between the second embodiment and the first embodiment is that the shape of the main body 21 is different. The main body 21 is made of elastic material and has a "U"-shaped structure with an opening facing the side of the support plate 1. The plates 24 are provided at both ends of the main body portion 21 and protrude outward thereof. In this embodiment, a solution in which the clamping plate 24 is integrally formed with the main body portion 21 is preferred. When installing, press the main body part 21 to make its opening smaller, release the clamping plate 24 when it is aligned with the clamping hole 17 on the support plate 1, and the clamping plate 24 enters the clamping hole 17 to realize smooth assembly. Those skilled in the art should understand that, in this embodiment, the elastic material used for the main body part 21 should have certain hardness, such as: hard plastic, wood, metal and so on.

[0046] ...

Embodiment 3

[0048] Such as Figure 10 and Figure 11 As shown, similar to the first embodiment, the main body portion 21 of the limit block 2 is also in the shape of a cuboid. The difference between the third embodiment and the first embodiment is that the side of the main body 21 close to the support plate 1 is attached with a mounting plate 241, and the mounting plate 241 and the main body 21 can be connected by screws, or can be bonded and screwed. The way of connection is to securely connect the mounting plate 241 to the main body 21 of the limit block 2 , and the clamping plate 24 is telescopically arranged at the upper and lower ends of the mounting plate 241 . In addition, it also includes a lock core 8 for controlling the expansion and contraction of the clamping plate 24 , and the main body 21 is provided with an accommodating hole (not shown in the figure) for accommodating the lock core 8 . When the limit block 2 is installed on the support plate 1, the locking plate 24 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com