Remote control method and system for master station system and station end system

A station-side and master-station technology, which is applied in the field of remote control systems between the master station system and the station-side system, can solve problems such as false control, incorrect association between remote control points and remote control objects, etc., so as to improve reliability, eliminate hidden dangers of false remote control, The effect of preventing false remote control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

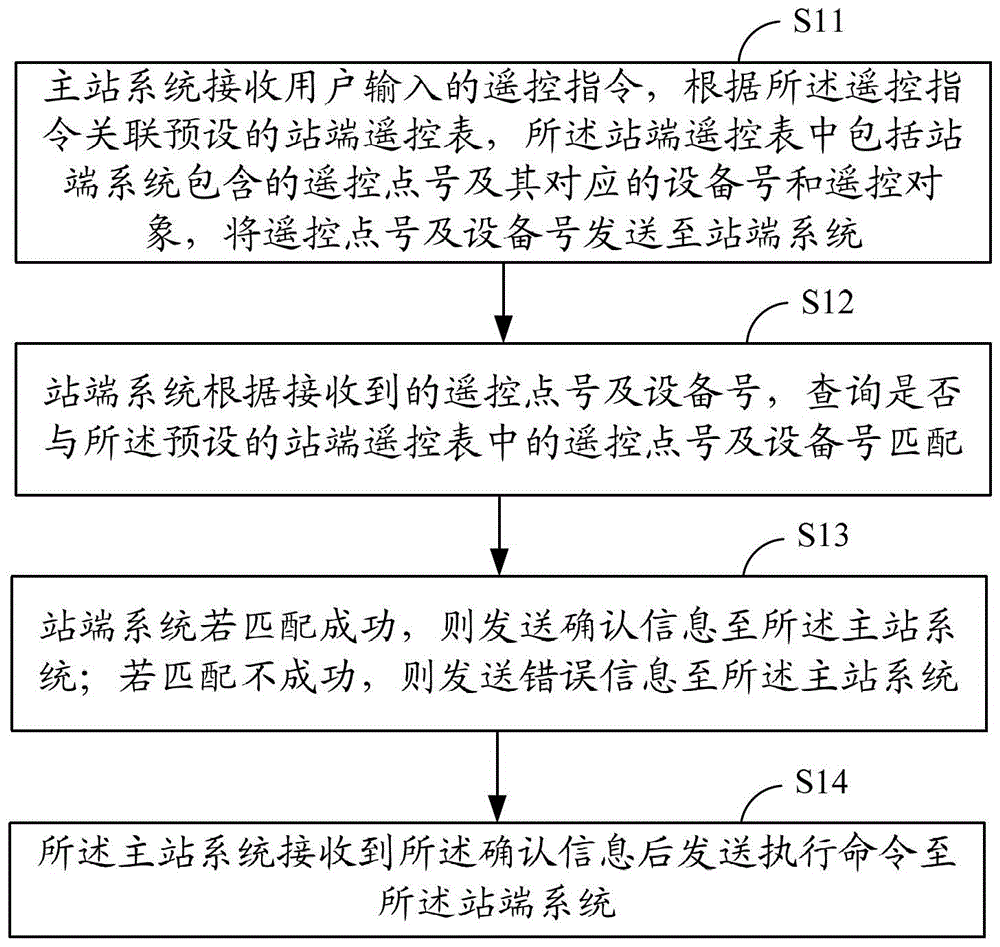

[0035] like figure 1 As shown, it is a schematic flow chart of the remote control of the master station system and the station-end system in an embodiment of the present invention. This embodiment illustrates the present invention from the interaction between the master station system and the station-end system, including the following steps:

[0036] S11. The master station system receives the remote control instruction input by the user, and associates the preset station-side remote control table according to the remote control command. The station-side remote control table includes the remote control point number and its corresponding equipment number and remote control Object, send the remote point number and equipment number to the station system;

[0037] S12. The station-side system checks whether the received remote control point number and device number match the remote control point number and device number in the preset station-side remote control table;

[0038] S...

Embodiment 2

[0047] This embodiment illustrates the processing process of the error in the association between the remote control point number and the remote control object in the station remote control table of the master station system;

[0048] The following table is a schematic form of the station-side remote control meter:

[0049]

[0050] As shown in the above table, due to the negligence of the automation personnel, when associating the remote control object, the remote control object "#1 high switch" is associated with the point number "2". Since the device number "101" corresponds to the remote control object, it does not There will be changes. When performing remote control on "#1 variable height switch", when this technology is not applied, the master station system only sends the remote point number "2" to the station-side system, and the station-side system returns confirmation after confirming that the point number exists Signal, after the remote control is executed, it ...

Embodiment 3

[0052] This embodiment illustrates the process of processing errors in the sequence of station-side remote control meters in the station-side system;

[0053] The following table is another schematic form of the remote control meter at the station:

[0054]

[0055] As shown in the table above, due to operational errors in the station system, the remote control table is inconsistent with the master station system. When the "#1 variable height switch" is remotely controlled, when this technology is not applied, the master station system only sends the remote control point number "1 "To the station-side system, after confirming the existence of the point number, the station-side system returns a confirmation signal, and after the remote control is executed, it will operate the remote control object "#1 high 01 isolation switch", resulting in misoperation. After applying this technology, the master station system will send the remote point number "1" and the device number "101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com