High-image-quality minitype optical lens of full plastic lens structure

A technology of plastic lens and optical lens, applied in the field of infrared wide-angle optical lens, can solve the problems of large thickness of lens, low pixel, large size, etc., and achieve the effect of high sensitivity and high sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

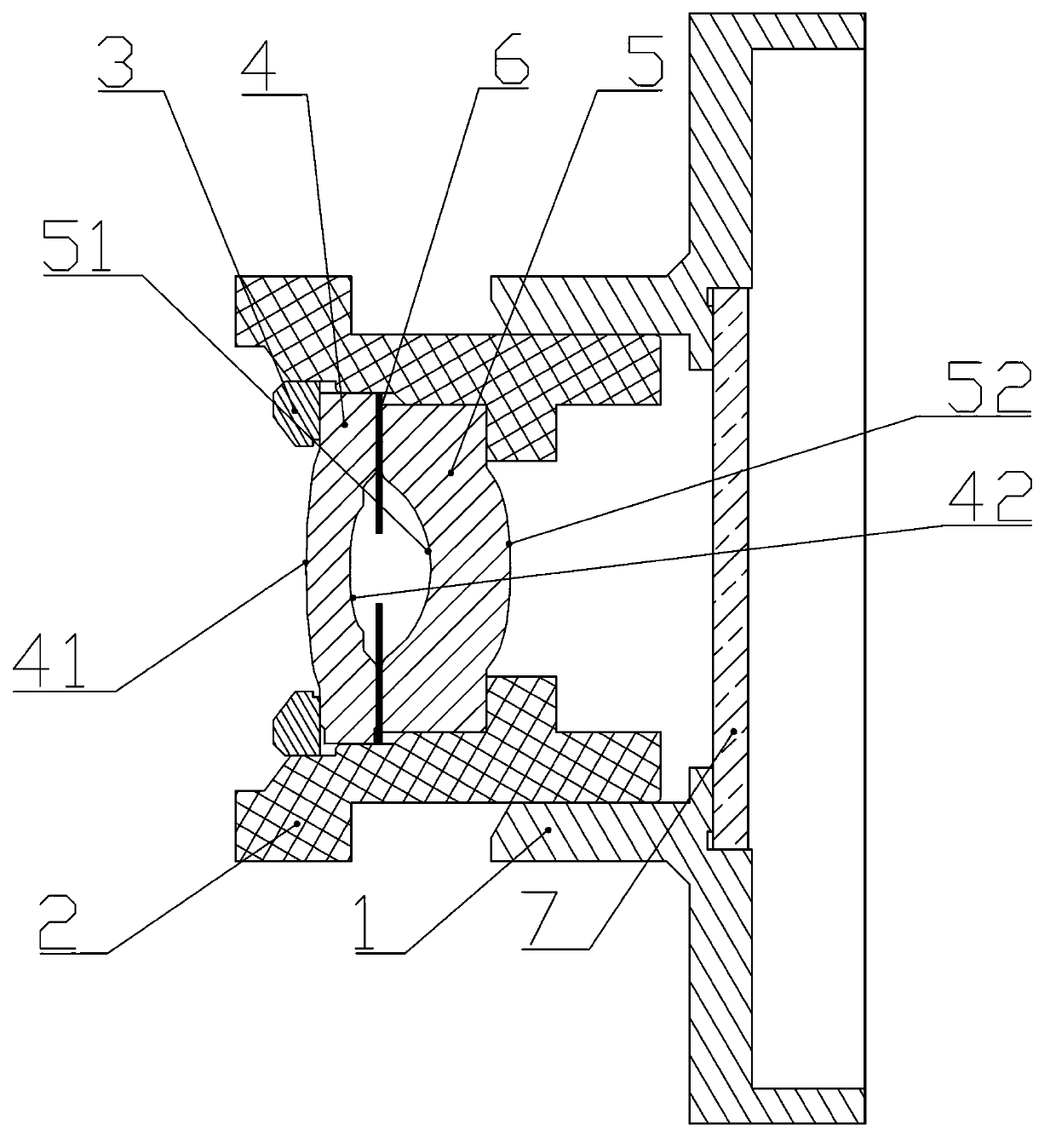

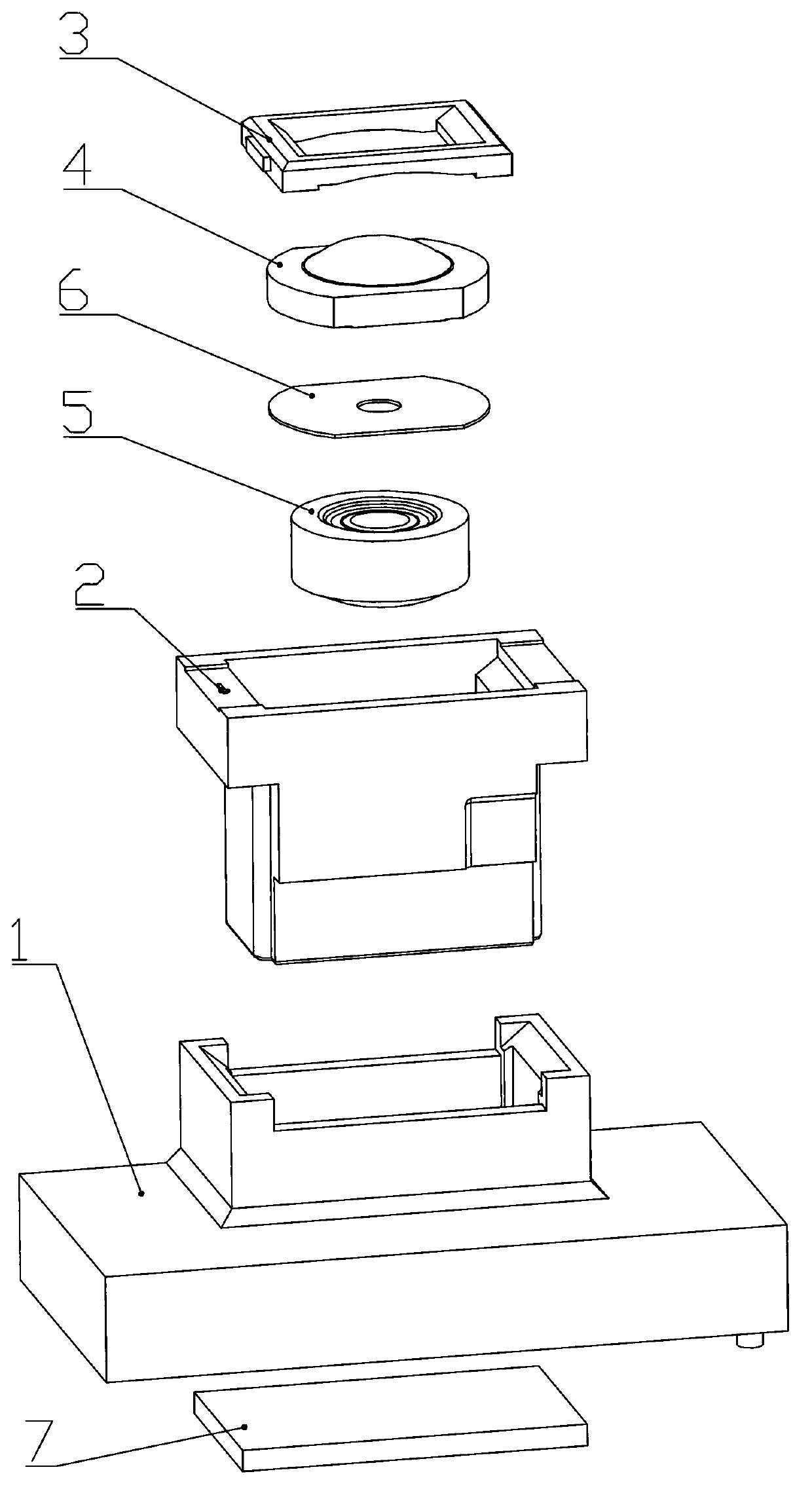

[0022] Such as figure 1 As shown, a high-quality micro-optical lens with an all-plastic lens structure can be used for relatively cheap high-pixel CMOS photosensitive sheets, including a seat 1 and a lens barrel 2 connected to the seat, and the cavity of the lens barrel 2 A pressure ring 3, a first lens 4, and a second lens 5 are sequentially provided in the center from outside to inside, and a spacer ring 6 is arranged between the first and second lenses. The first lens 4 is a negative focal length lens, the first surface 41 facing the object side is an oblate aspheric surface, and the second surface 42 facing the image side is a hyperbolic aspheric surface. The second lens 5 is a positive focal length lens, the first surface 51 facing the object side is a circular aspheric surface, and the second surface 52 facing the image side is a hyperbolic aspheric surface. The shape ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap