Injection molding machine

A technology of injection molding machine and mold clamping force, which is applied in the field of injection molding machines and can solve the problem that the detection results of sensors are not fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In each of the drawings, the same or corresponding components are given the same or corresponding symbols and descriptions thereof are omitted.

[0028] (mold clamping device)

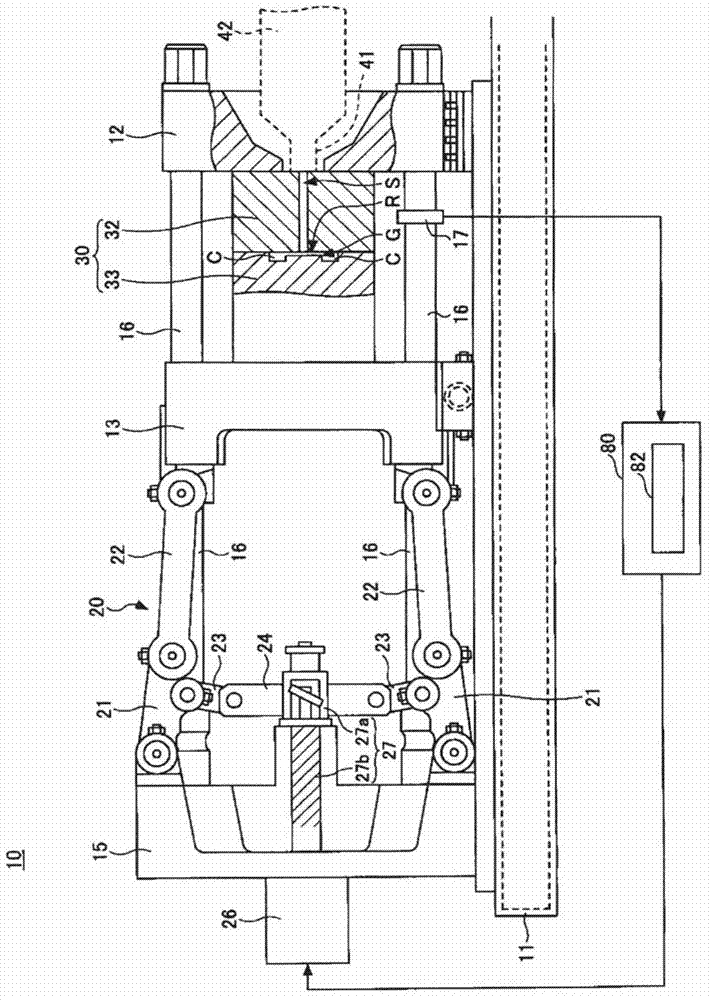

[0029] figure 1 It is a figure which shows the clamping apparatus of the injection molding machine which concerns on one Embodiment of this invention. figure 1 Indicates the clamping status. In the description of the mold clamping device, the moving direction of the movable platen when the mold is closed is referred to as the front, and the direction of movement of the movable platen when the mold is opened is described as the rear.

[0030] The injection molding machine 10 includes: a frame 11; a fixed platen 12 fixed to the frame 11; A plurality of (for example four) connecting rods 16 are erected between the fixed platen 12 and the toggle support member 15 .

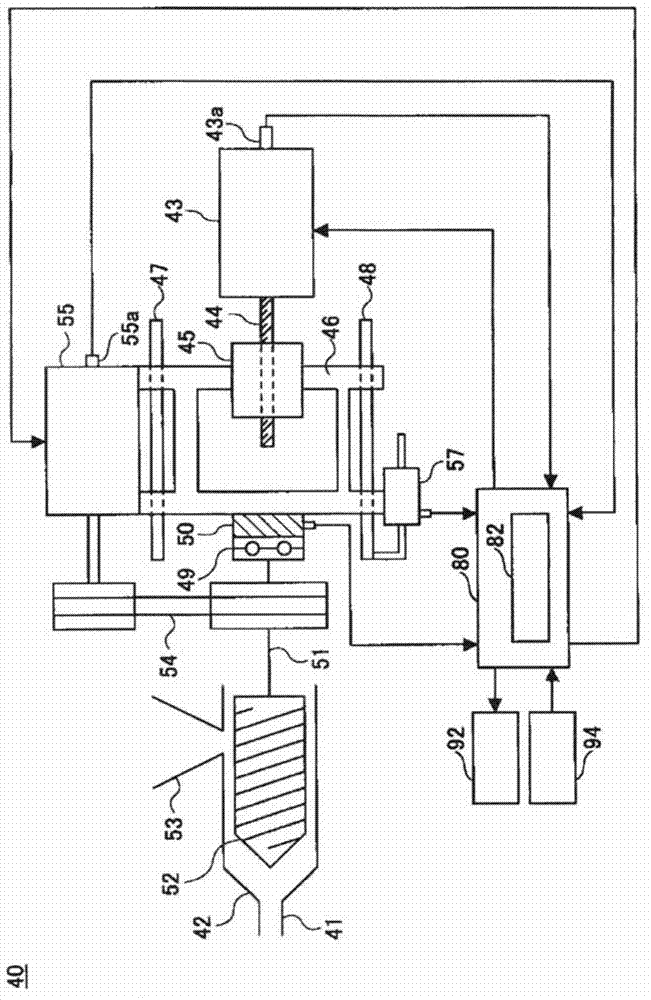

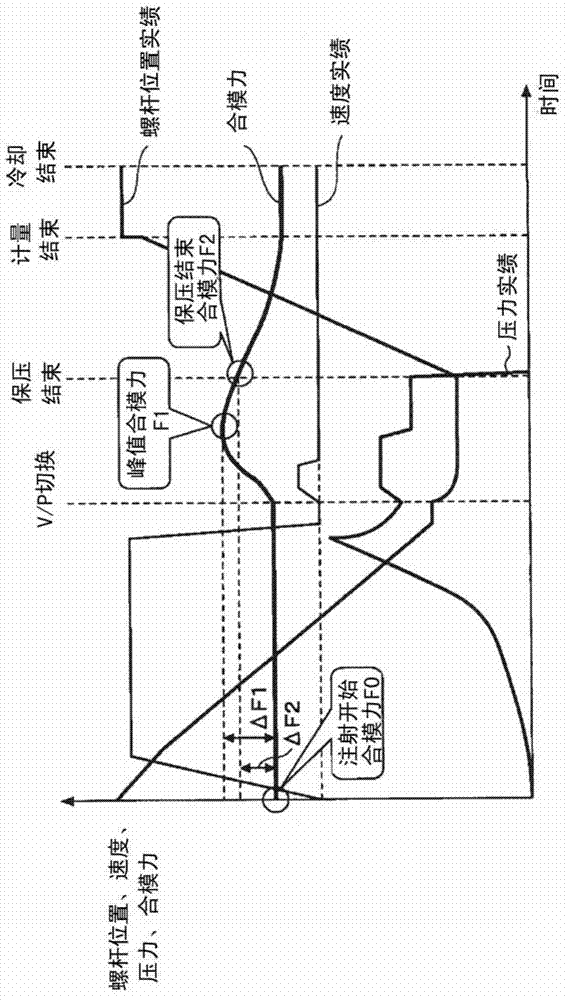

[0031] The injection m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap