Differential transformer type control bar position detector

A control rod position and differential transformer technology, applied in nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of non-contact position monitoring device principle selection difficulties, etc., to achieve convenient disassembly and installation, reliable and stable installation, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

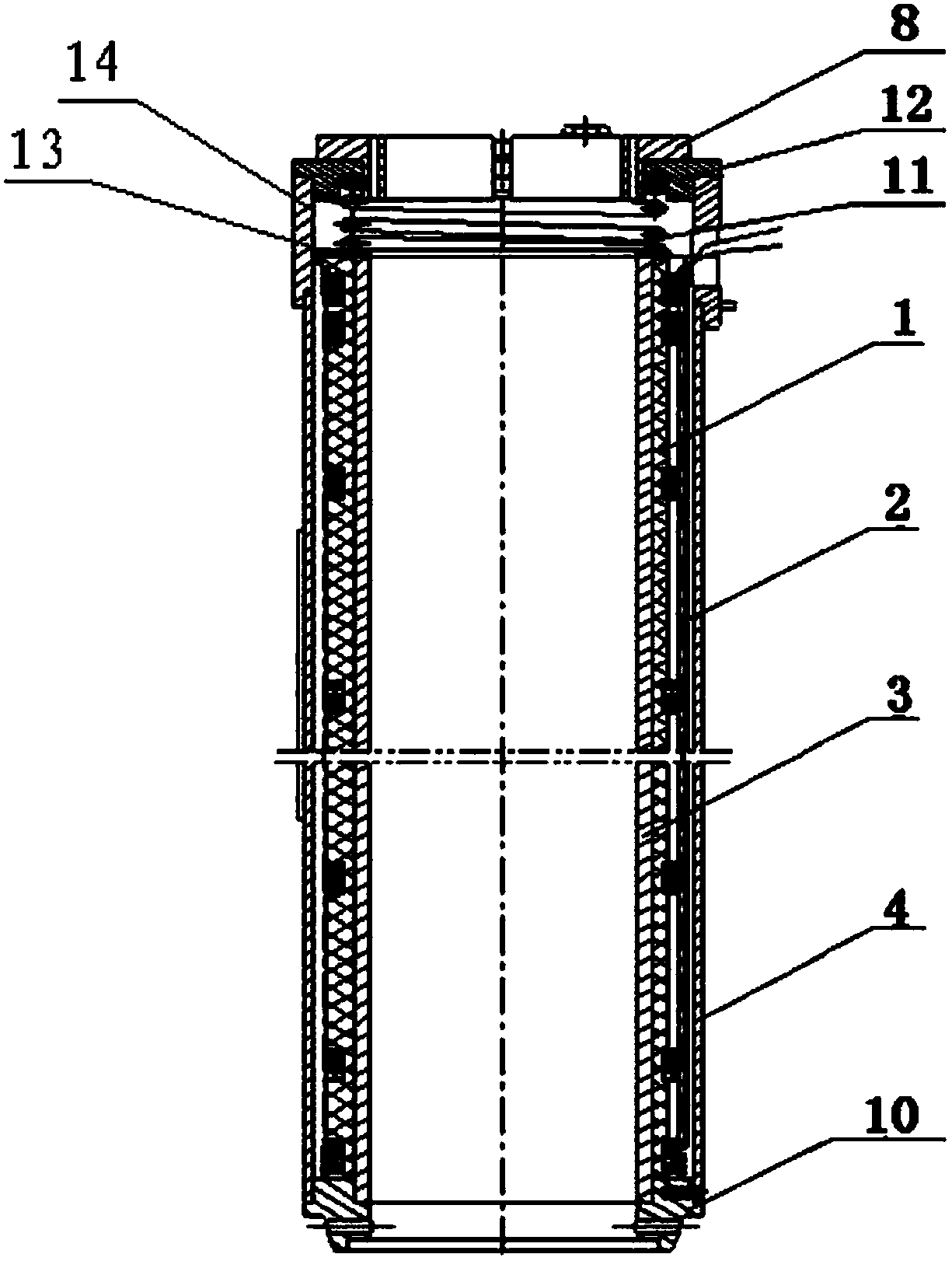

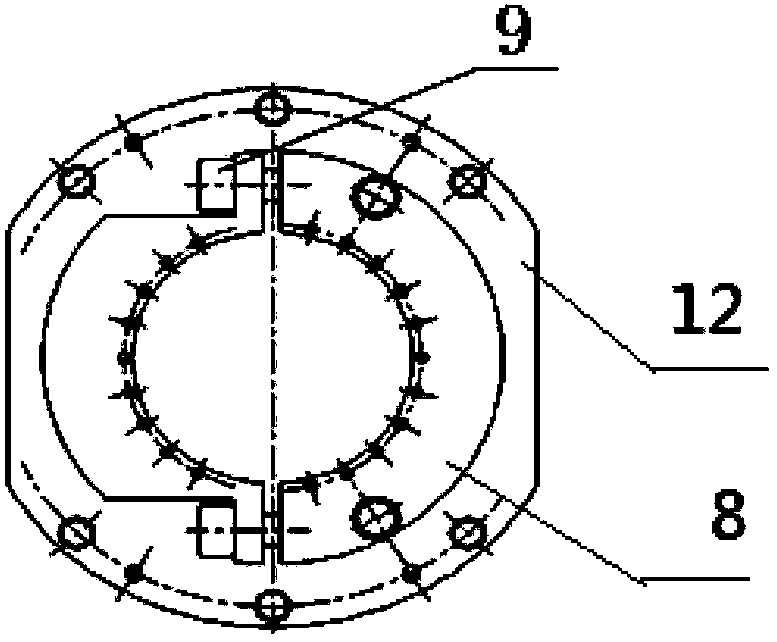

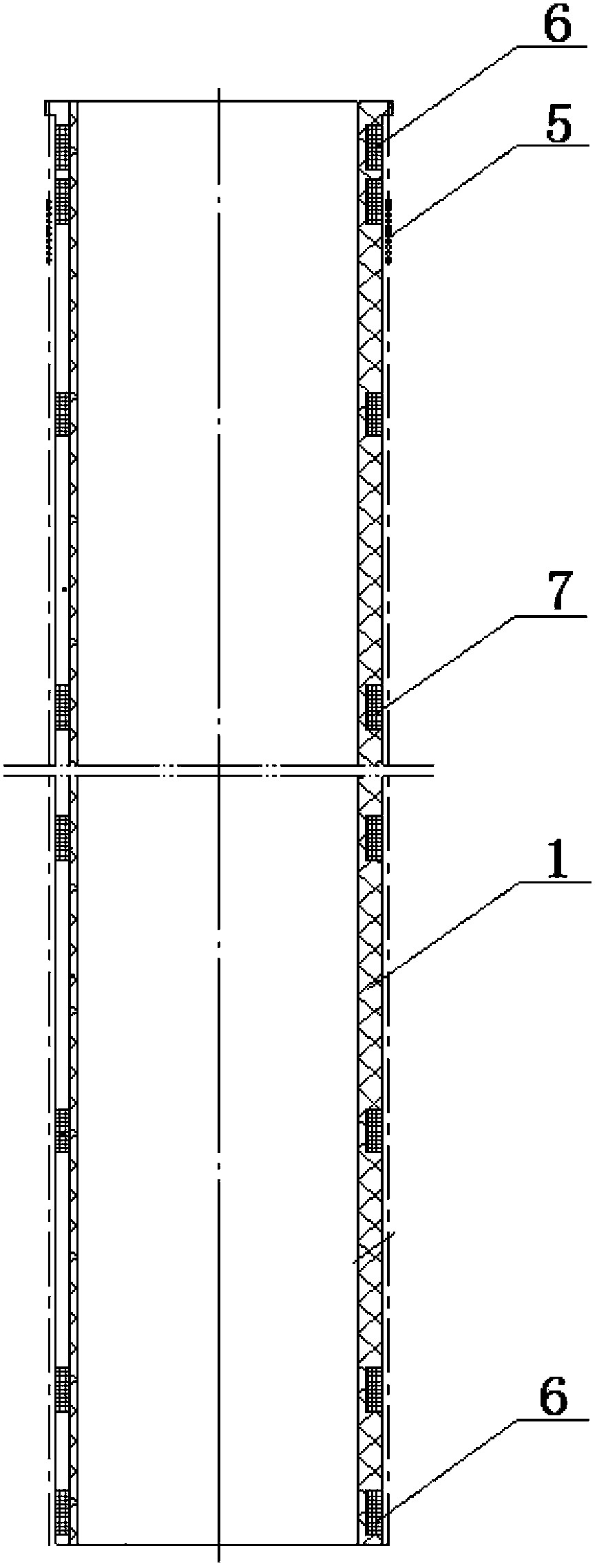

[0016] Such as Figure 1a , Figure 1b and figure 2 As shown, the bobbin 1 is a thin-walled cylinder made of non-magnetic material, 0Cr19Ni9 is used in this embodiment. Ring grooves are respectively symmetrically processed on the upper, lower and middle parts of the coil bobbin 1 .

[0017] The rod position detection coil 2 is composed of a primary coil 5, two compensation coils 6 and several secondary coils 7. In this embodiment, there are 6 secondary coils 7, and the compensation coils 6 are wound on the upper and lower ends of the bobbin 1. The secondary coil 7 is wound in the annular groove in the middle of the bobbin 1 . The primary coil 5 is wound on the outer wall of the entire coil bobbin 1 to cover the entire coil bobbin 1, and the coil end is wound in multiple layers to ensure that both sides of the secondary coil at the end are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap