Set of beverage preparation machines differing by their sizes

A beverage and machine technology, applied in the field of beverage production machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

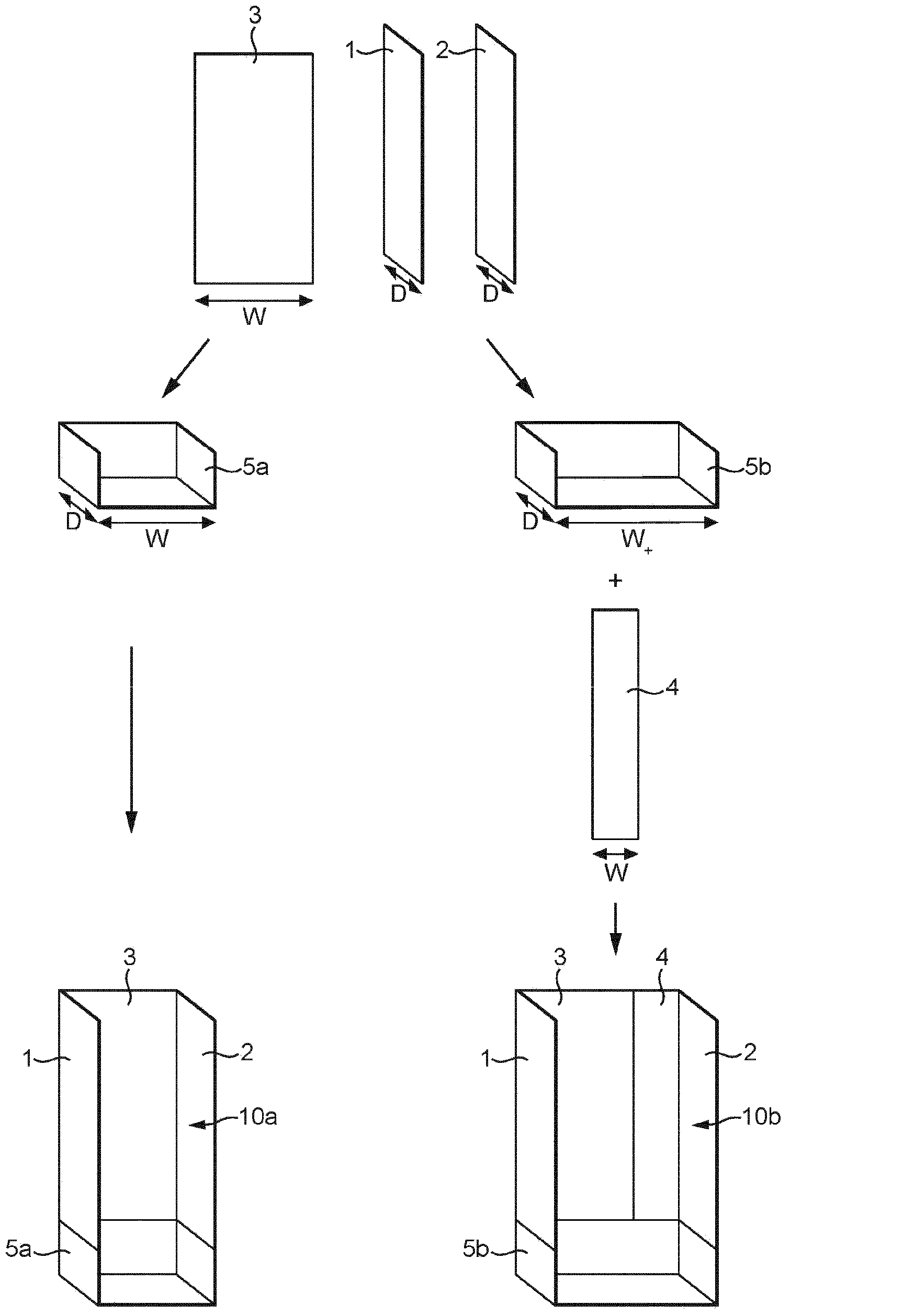

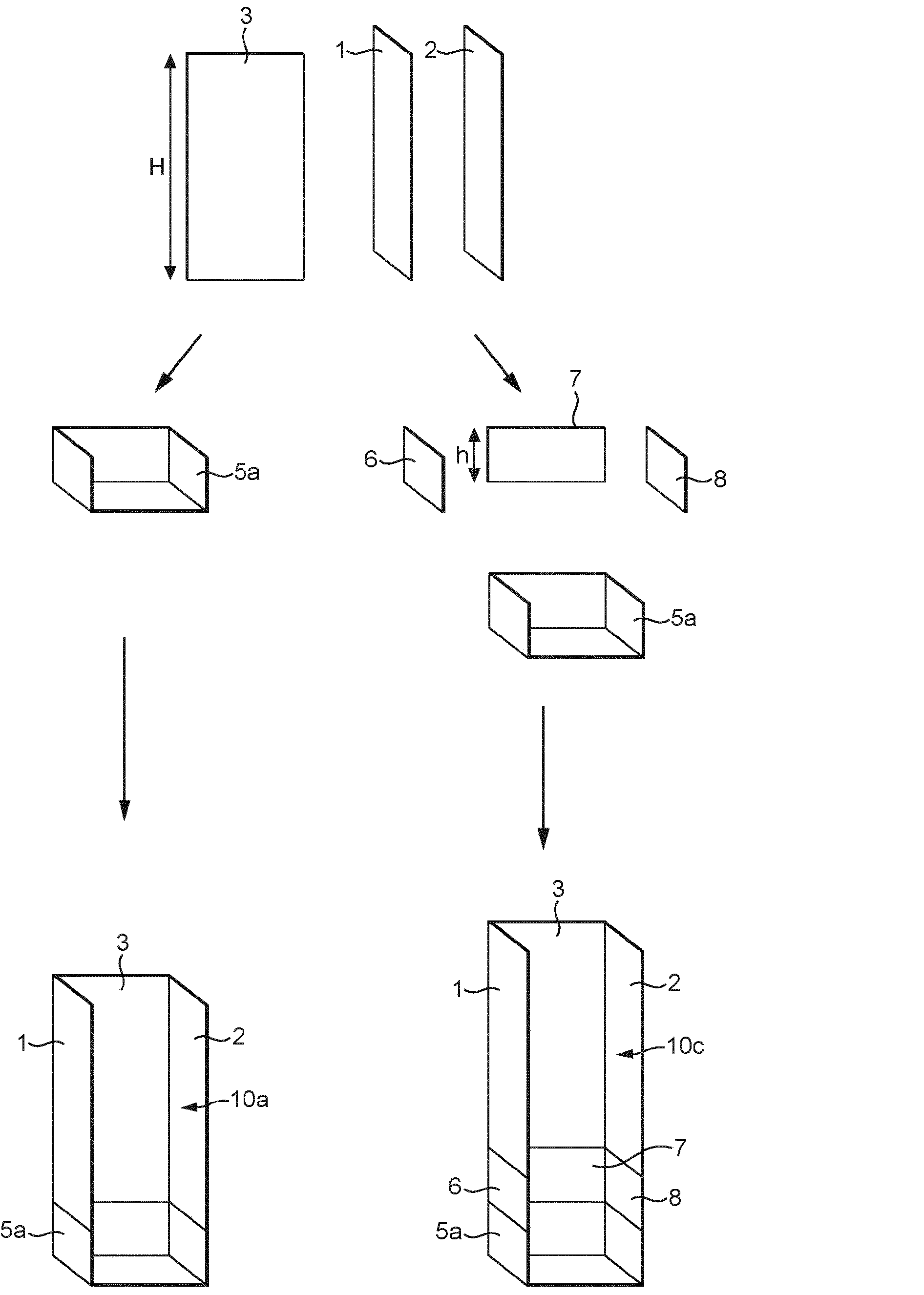

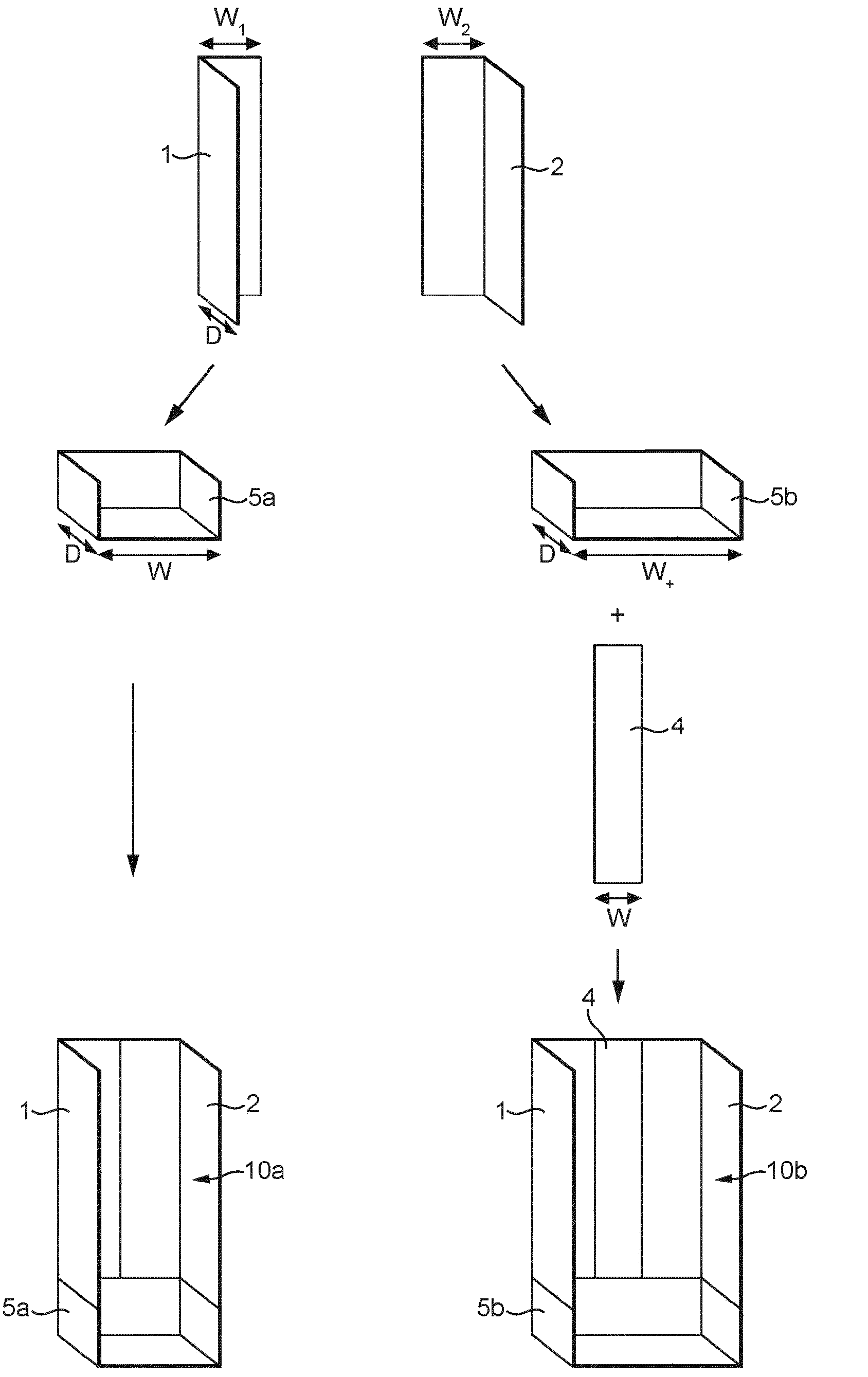

[0042] figure 1 and figure 2 A method of constructing housings 10a, 10b, 10c of three different beverage production machines from the same group of machines is shown. The shells described above are produced starting from the same common core elements (left core shell plate, right core shell plate and rear core shell plate).

[0043] according to figure 1In the first mode, the left core shell plate 1, the right core shell plate 2 and the rear core shell plate 3 are three separate plates. These plates are substantially flat. These three core plates can be connected to a small bottom shell 5a or a large bottom shell 5b, depending on the desired size of the dispenser. The two bottom shells 5a, 5b have different width dimensions, the small bottom shell 5a has a width W, and the large bottom shell 5b has a width W greater than the width W. + . The core shell plates 1, 2, 3 are configured such that the left and right core shell plates have the same length dimension D as the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com