Hollow composite bra cup structure

A composite, cup technology, applied in bras, clothing, applications, etc., can solve the problems of unable to achieve foil, repair breast shape, easy to produce a sense of restraint, unable to fully fit female breasts and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

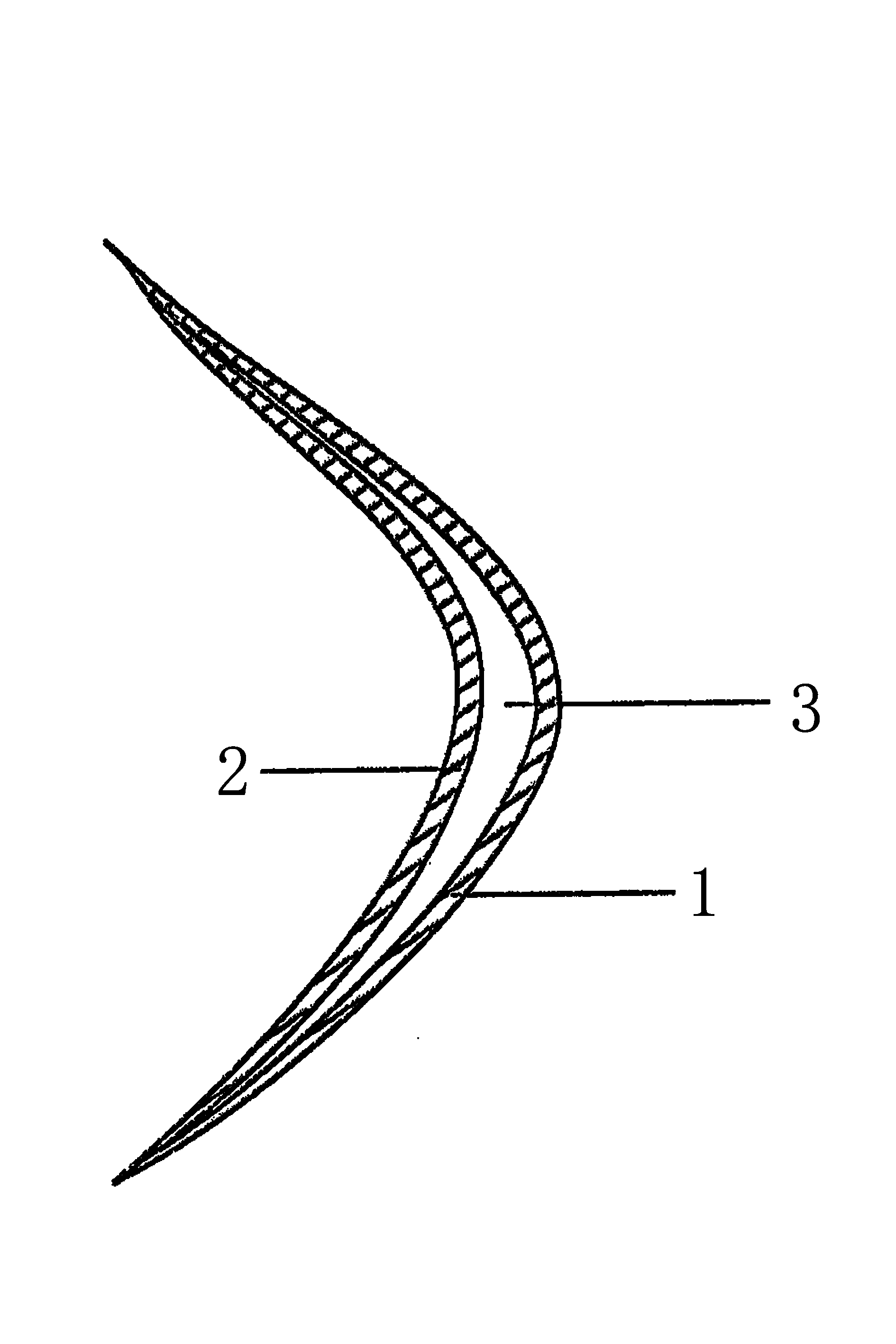

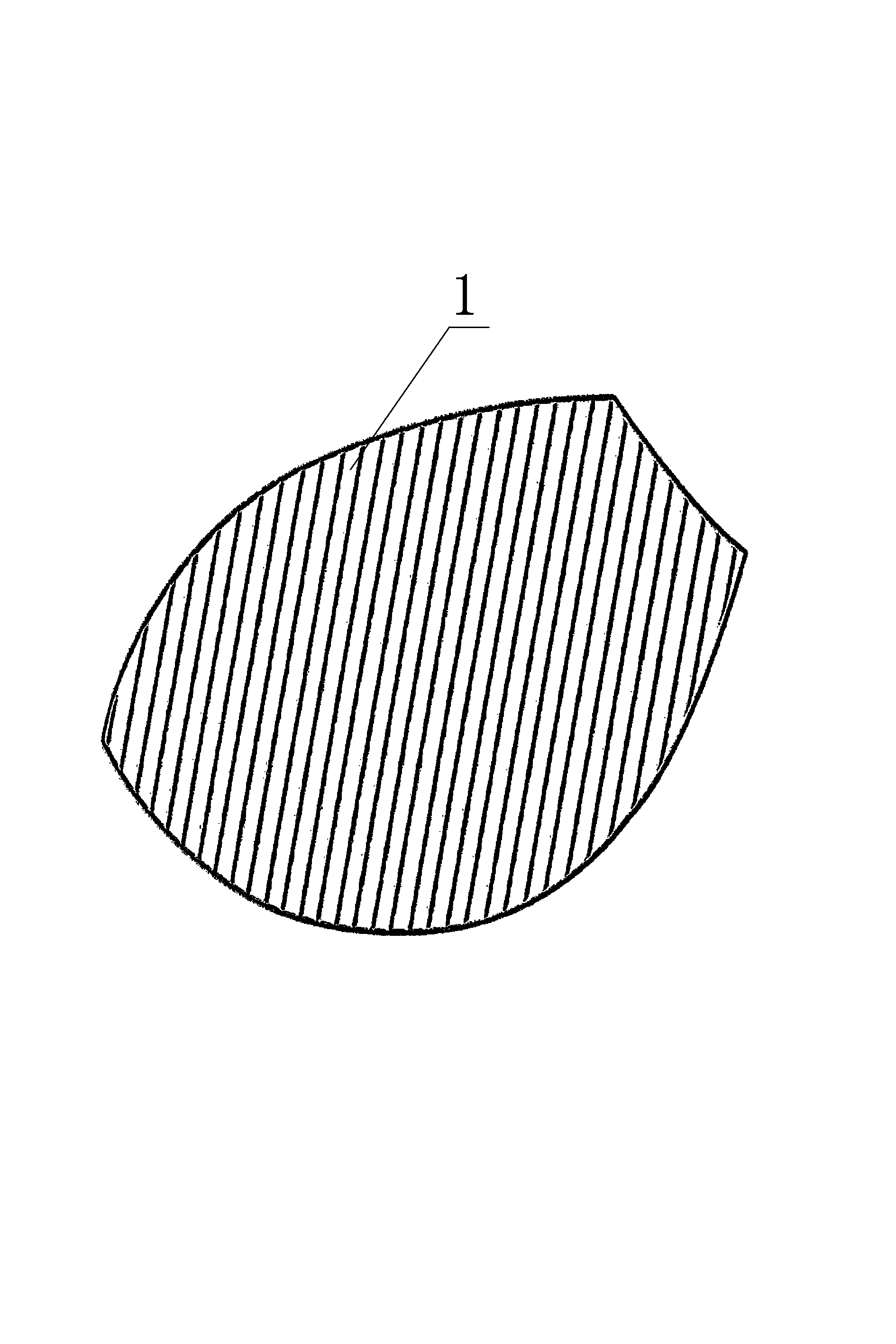

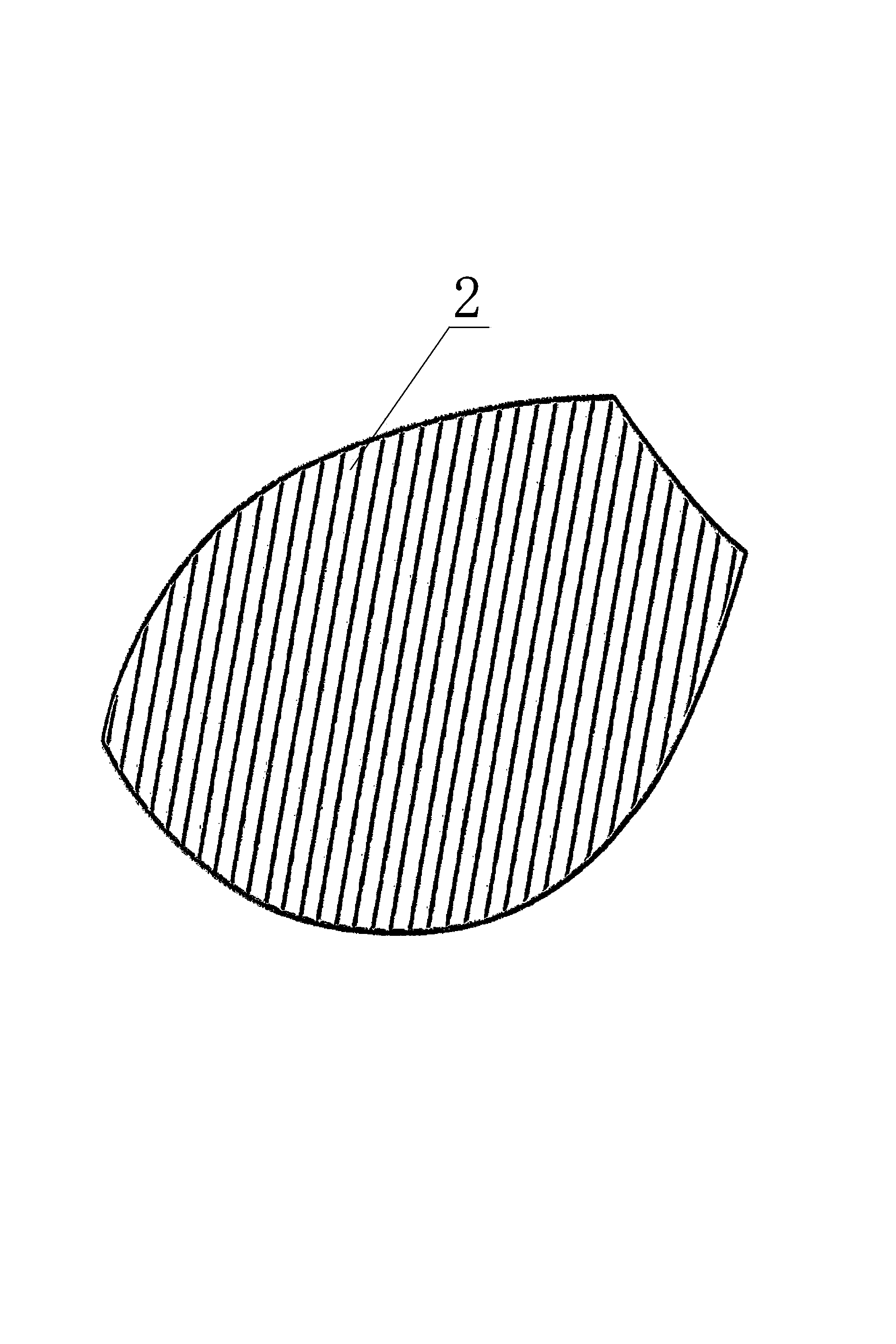

[0011] The invention discloses a hollow compound cup structure, which includes a cup body, characterized in that: the cup body is composed of a front cup 1 and an inner cup 2, the edges of the front cup 1 and the inner cup 2 are attached to each other, and the front cup A hollow cavity 3 is formed between the 1 and the inner cup, and the hollow cavity 3 makes the cup itself have good plasticity.

[0012] During specific implementation, the surface cup 1 forms an arc-shaped bulge to one side, and the inner cup also forms an arc-shaped bulge to one side, and the edges of the two form a closed fit with each other. The hollow cavity 3 also forms an arc-shaped bulge to one side. The above-mentioned structure makes the cup form a three-dimensional structure, and the front cup 1 and the inner cup 2 have different functions. The outer cup 1 can make the appear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com