High-crushing ratio jaw crusher

A jaw crusher and crushing ratio technology, applied in grain processing and other directions, can solve problems such as restricting crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

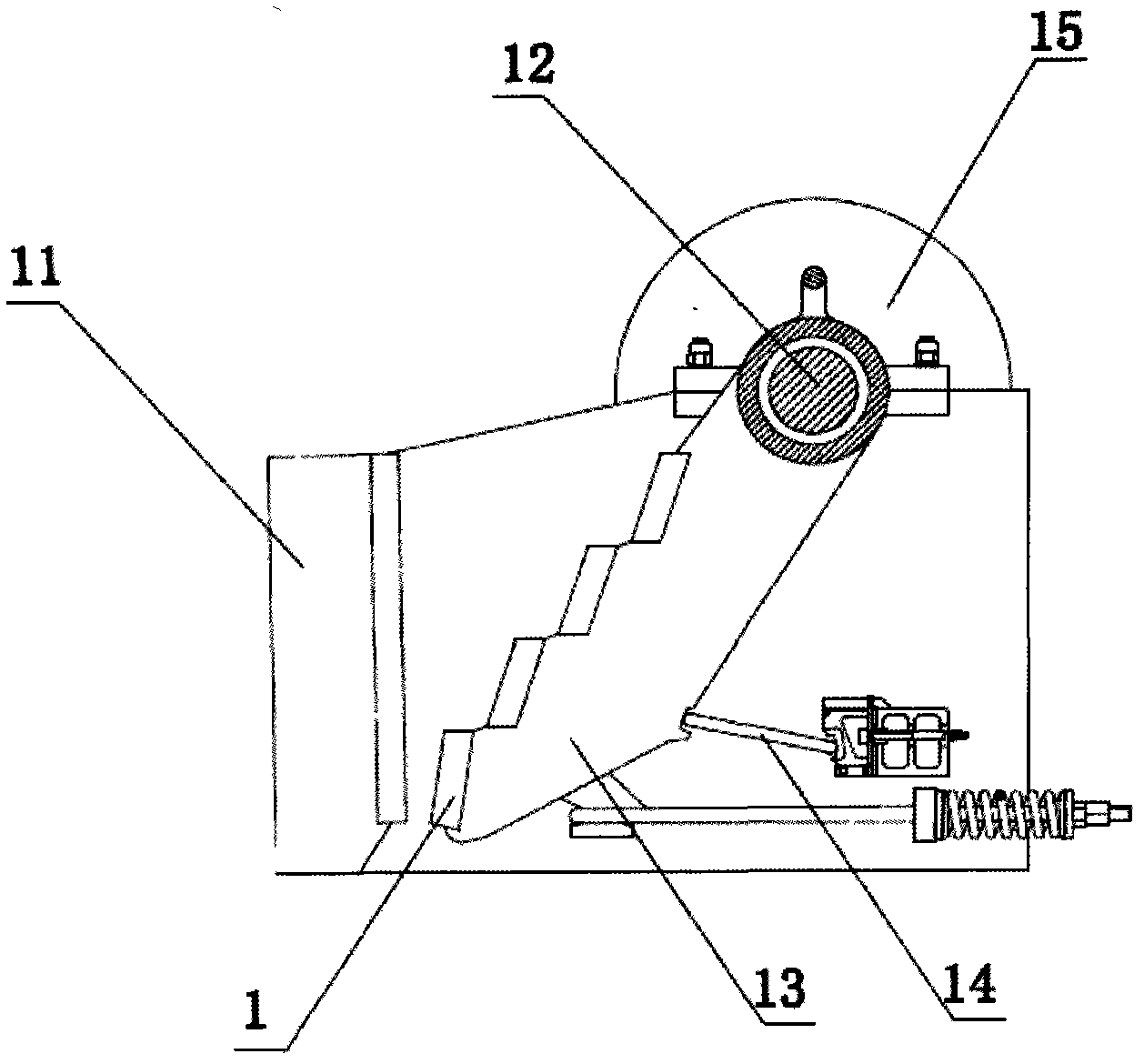

[0090] Embodiment 1: as figure 1 and Figure 4 As shown, a jaw sand making machine includes a frame 11, an eccentric drive shaft mechanism, a movable jaw mechanism, a toggle plate mechanism and a secondary crushing mechanism, the eccentric drive shaft mechanism includes an eccentric drive shaft 12, and the movable jaw mechanism includes A movable jaw 13, the toggle mechanism includes a toggle 14;

[0091] The upper end of the movable jaw 13 is connected with the eccentric drive shaft 12 , and the lower end is connected with the front end of the toggle plate 14 ; the rear end of the toggle plate 14 is connected with the frame 11 . The eccentric drive shaft 12 is connected to the transmission wheel 15 .

[0092] like Figure 4 As shown, the crushing auxiliary mechanism is composed of two opposing crushing surfaces, one of which is composed of four jaw plates 1 combined up and down; the four jaw plates 1 that make up the crushing surface are separated and spliced to form a s...

Embodiment 2

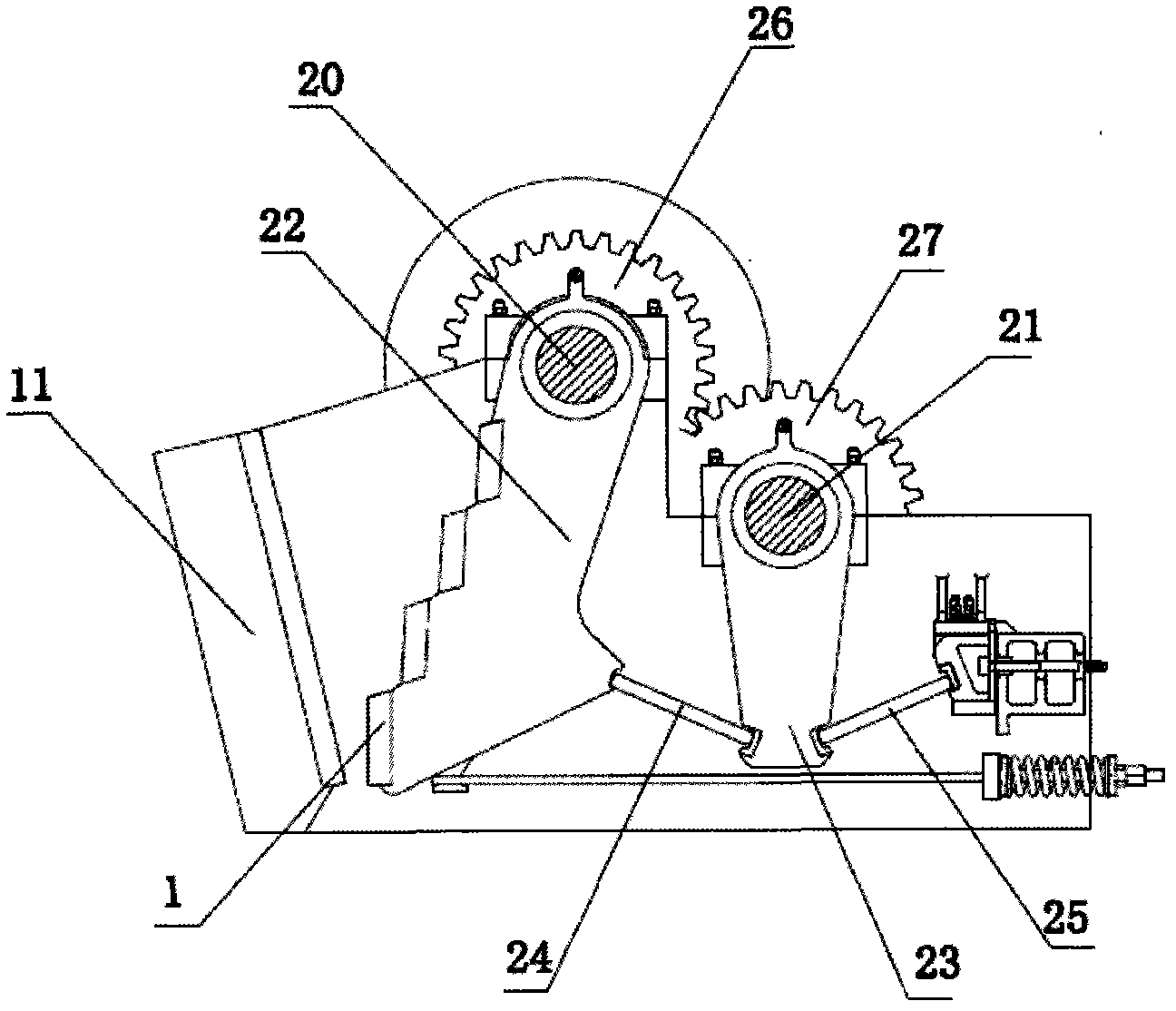

[0096] Embodiment 2: as figure 2 As shown, the eccentric drive shaft mechanism includes a front eccentric drive shaft 20 and a rear eccentric drive shaft 21, the movable jaw mechanism includes a front movable jaw 22 and a rear movable jaw 23, and the toggle plate mechanism includes a front toggle plate 24 and a rear movable jaw bracket 25;

[0097]The upper end of the front movable jaw 22 is connected to the front eccentric drive shaft 20, and the lower end is connected to the front end of the front toggle plate 24; the rear end of the front toggle plate 24 is connected to the lower end of the rear movable jaw 23;

[0098] The upper end of the rear movable jaw 23 is connected with the rear eccentric drive shaft 21 , and the lower end is connected with the front end of the rear toggle plate 25 ; the rear end of the rear toggle plate 25 is connected with the frame 11 .

[0099] The front eccentric drive shaft 20 and the rear eccentric drive shaft 21 are connected with the fron...

Embodiment 3

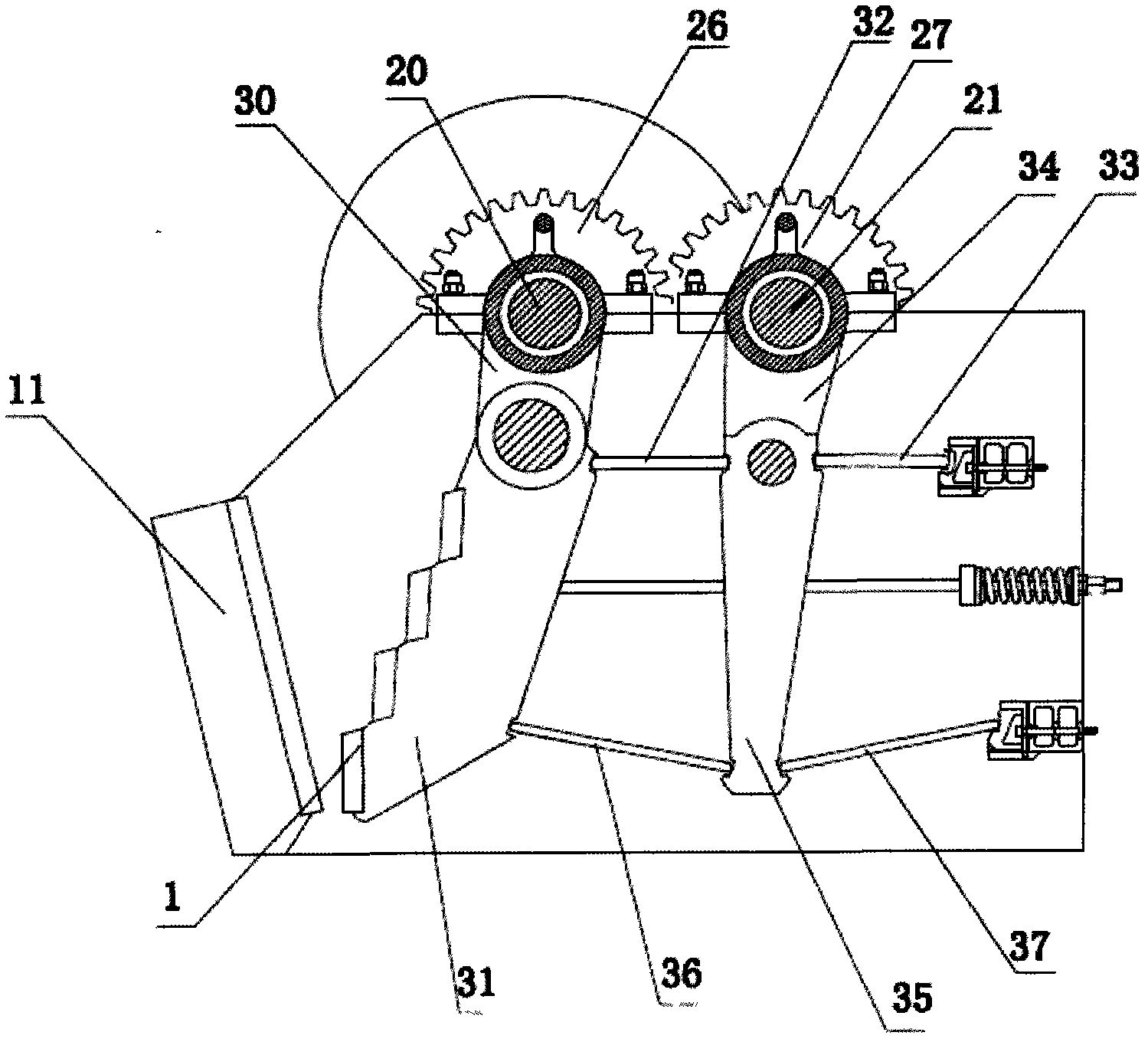

[0101] Embodiment 3: as image 3 As shown, the eccentric drive shaft mechanism includes a front eccentric drive shaft 20 and a rear eccentric drive shaft 21; the movable jaw mechanism includes an upper front movable jaw 30, a lower front movable jaw 31, an upper rear movable jaw 34 and a lower rear movable jaw 35. The toggle mechanism includes an upper front toggle plate 32, a lower front toggle plate 33, an upper rear toggle plate 36 and a lower rear toggle plate 37;

[0102] The upper end of the upper front movable jaw 30 is connected with the front eccentric drive shaft 20, the lower end is connected with the front end of the upper front toggle plate 32; the rear end of the upper front toggle plate 32 is connected with the lower end of the upper rear movable jaw 34;

[0103] The upper end of the upper rear movable jaw 34 is connected to the rear eccentric drive shaft 21, and the lower end is connected to the front end of the upper rear toggle plate 36; the rear end of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com