Outrigger leveling method and outrigger leveling system

A technology of outriggers and level gauges, which is applied in transportation and packaging, vehicle maintenance, lifting vehicle accessories, etc. It can solve the problems of insufficient tire clearance from the ground, affecting construction efficiency, time-consuming and labor-intensive problems, and achieves simple control and reduced repeated leveling The probability, the effect of improving the leveling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Below in conjunction with accompanying drawing, each preferred embodiment of the present invention is described further:

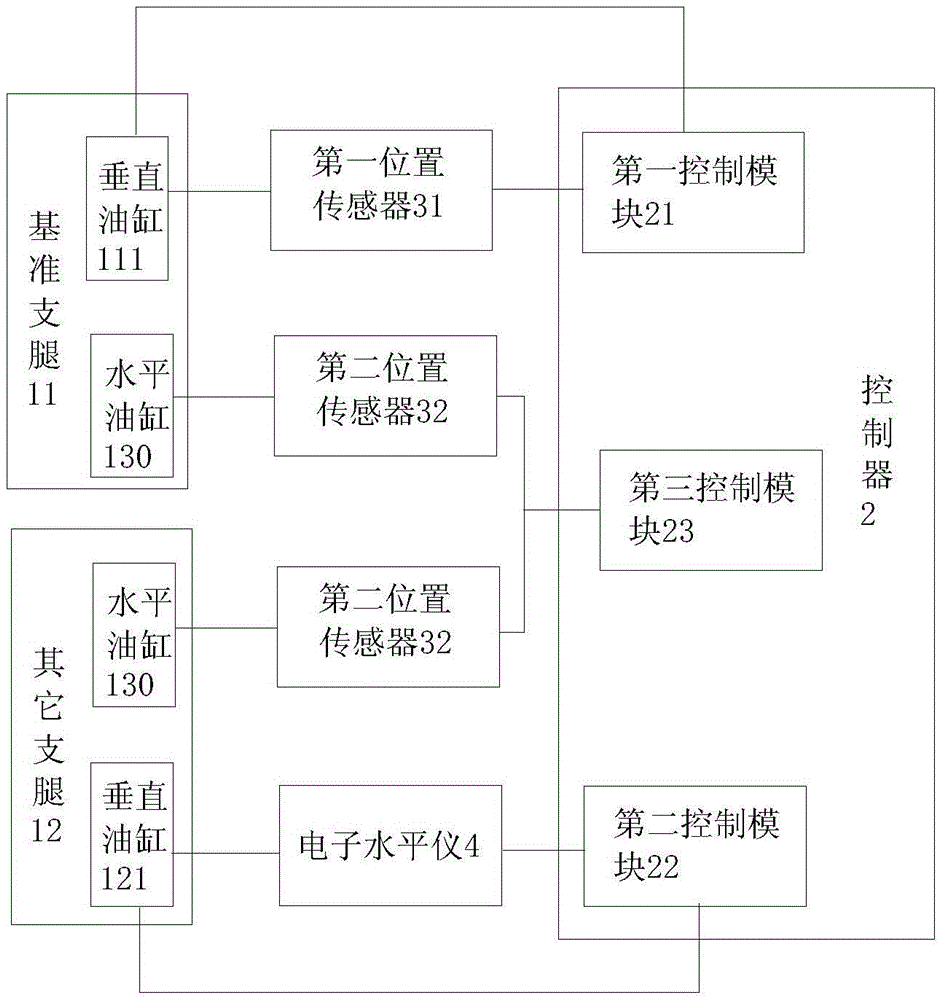

[0040] Embodiment 1 of the present invention provides a method for leveling outriggers, which is used for construction machinery, comprising the following steps:

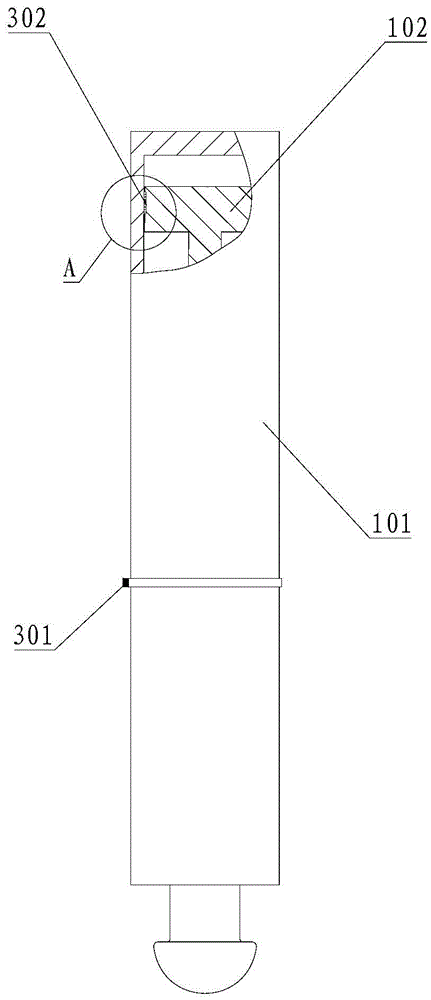

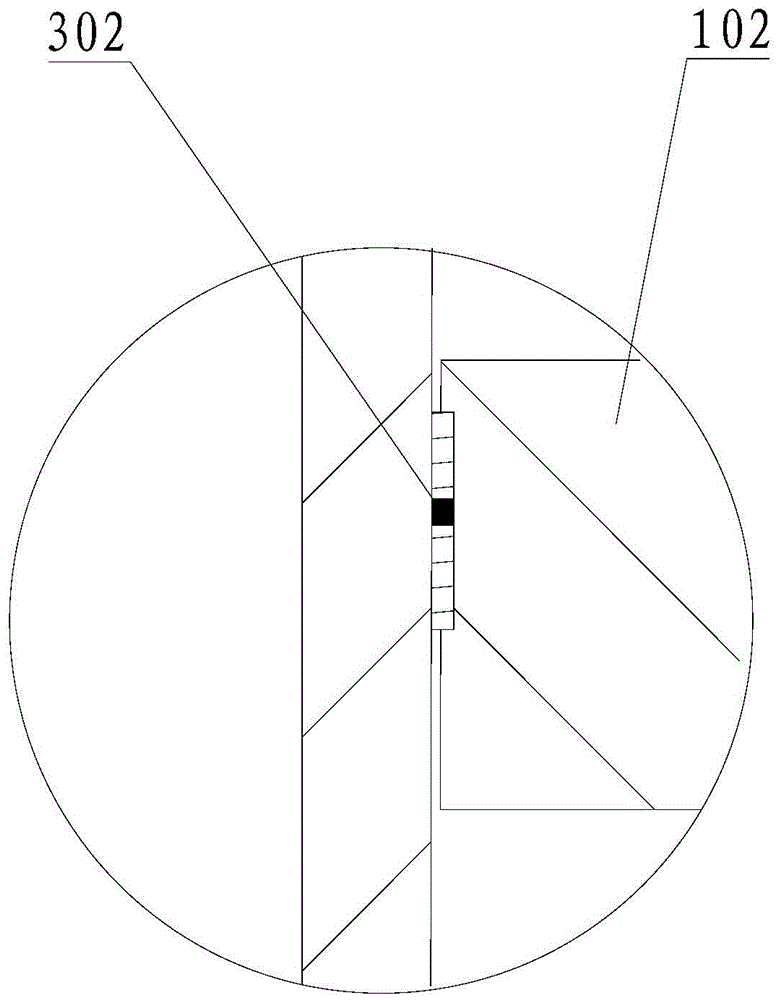

[0041] S1. The vertical oil cylinder that controls the reference outrigger stretches out the first preset length; wherein, the first preset length is not less than the length that the vertical oil cylinder extends when the tire of the construction machinery is at the minimum safe distance from the ground; the reference outrigger is each The outrigger with the shortest distance from the ground among the outriggers;

[0042] S2. Control the expansion and contraction of the vertical oil cylinders of the other legs until the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com