Glare shield equipped with emergency vision apparatus

A technology of visual devices and visors, which is used in aircraft indicating devices, optics, emergency equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

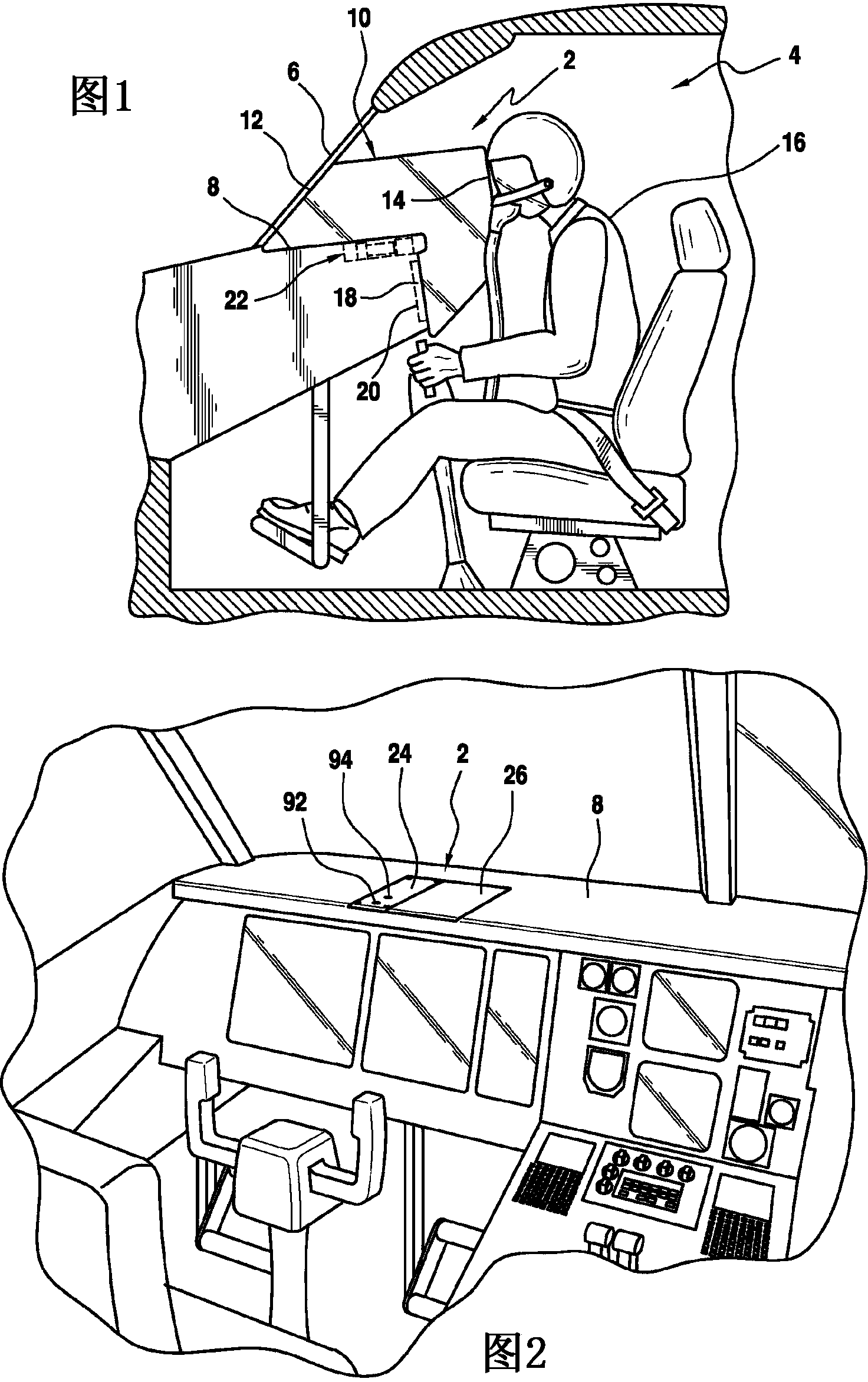

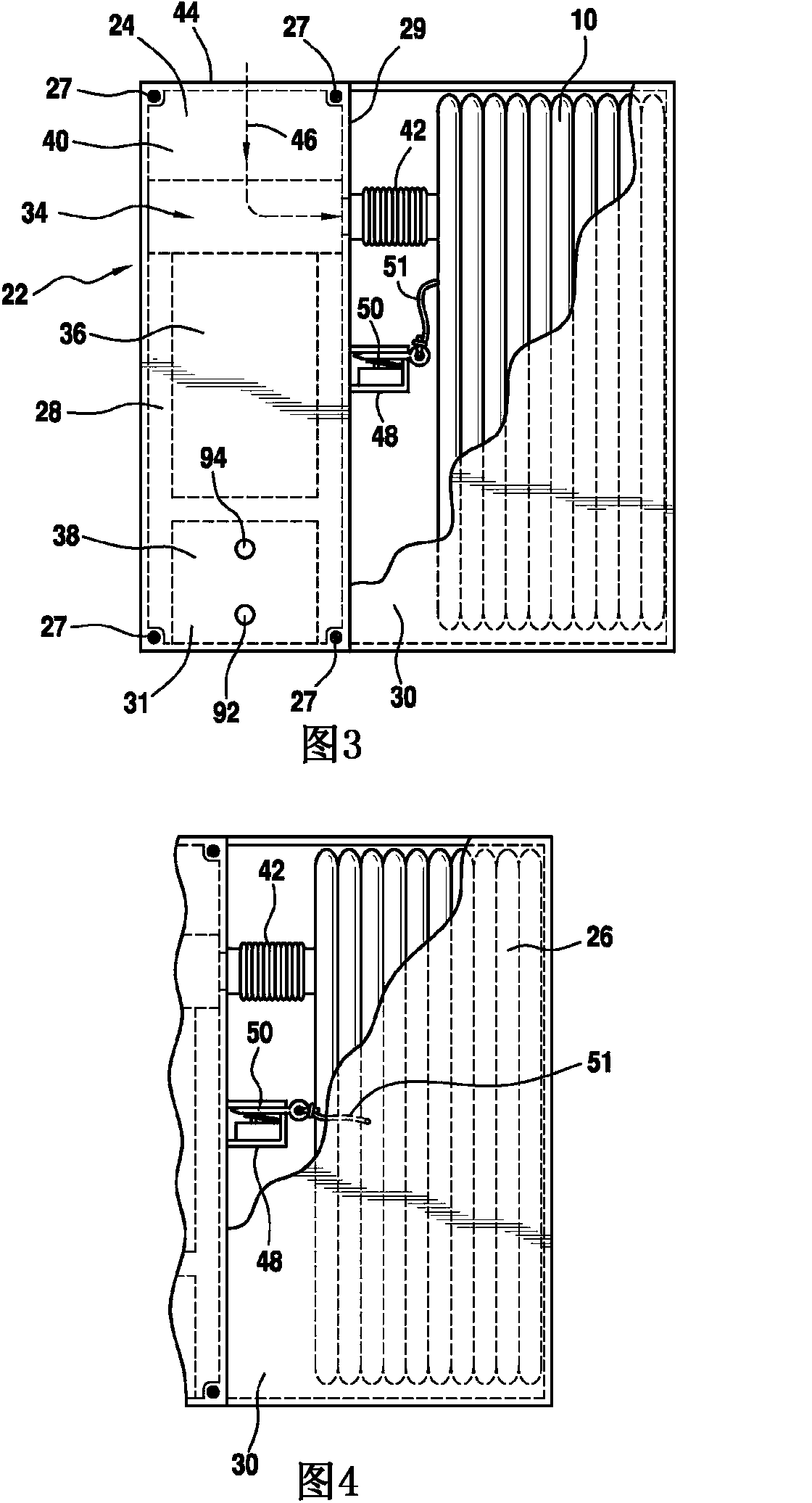

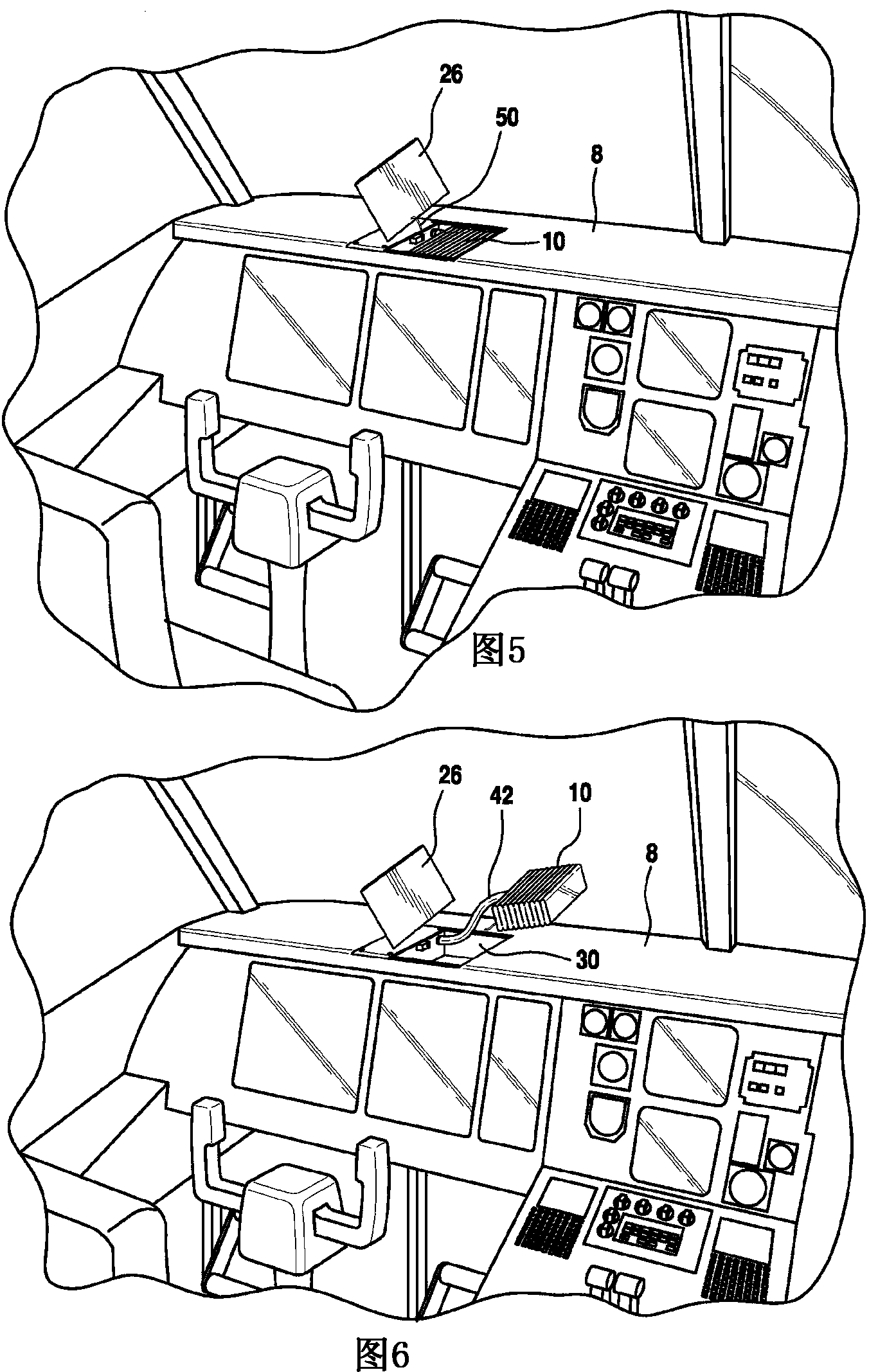

[0018] figure 1 Shown is an emergency vision device 2 integrated into a dashboard as an example according to the invention. The device 2 is applied to an operator station 4, such as an aircraft cockpit, so that the operator can see information sources, such as flight instruments, through the smoke in an emergency event of smoke. In the context of an aircraft cockpit, the operator station 4 includes a windshield 6 and a visor 8 . Apparatus 2 includes an inflatable enclosure 10 having a transparent member 12 and another transparent member 14 that allows an operator 16 to see through the enclosure 10 and windshield 6 in the event of a smoke emergency. This helps the operator control the aircraft and land it safely. The enclosure 10 also includes another transparent member 18 to facilitate the operator to observe the information on the instrument panel 20 . The device 2 comprises a compartment 22 located within the visor 8 . The location of the compartment 22 near where the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com