Novel road roller drum assembly

A technology of road rollers and rollers, applied in the field of parts and components on road rollers, can solve problems such as crushed panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

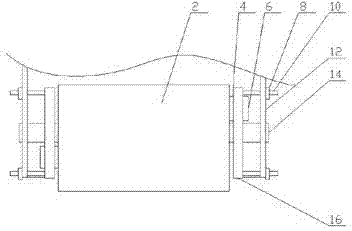

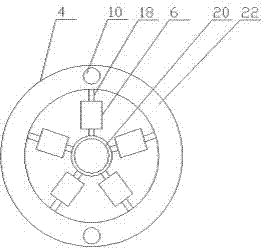

[0015] Such as figure 1 and figure 2 As shown, the present invention includes a drum 2 and a shaft body 14 axially penetrating the drum 2. The drum 2 can rotate around the shaft body 14, and the two ends of the shaft body 14 are respectively fixed on two panels 12 fixedly connected with the road roller body. A balance clamping device is respectively connected between the two ends of the panel 12 and the drum 2. The balance clamping device includes a roller 6 whose axis is parallel to any radius on the end surface of the drum 2. face tangent.

[0016] On both ends of the drum 2 there are rollers 6 that are tangent to it, and the drum 2 is clamped by the rollers 6, because there is a line contact between the rollers 2 and the rollers 6, so the rollers 6 will not hinder the The rolling of drum 2. However, it should be noted that the placement direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com