A method for characterizing the scale microstructure of hot-rolled steel plate cross-sections using ebsd

A technology of iron oxide scale and hot-rolled steel plate, which is applied in the use of wave/particle radiation for material analysis, measuring devices, instruments, etc., which can solve problems such as easy breakage, difficult preparation of iron oxide scale samples, and poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

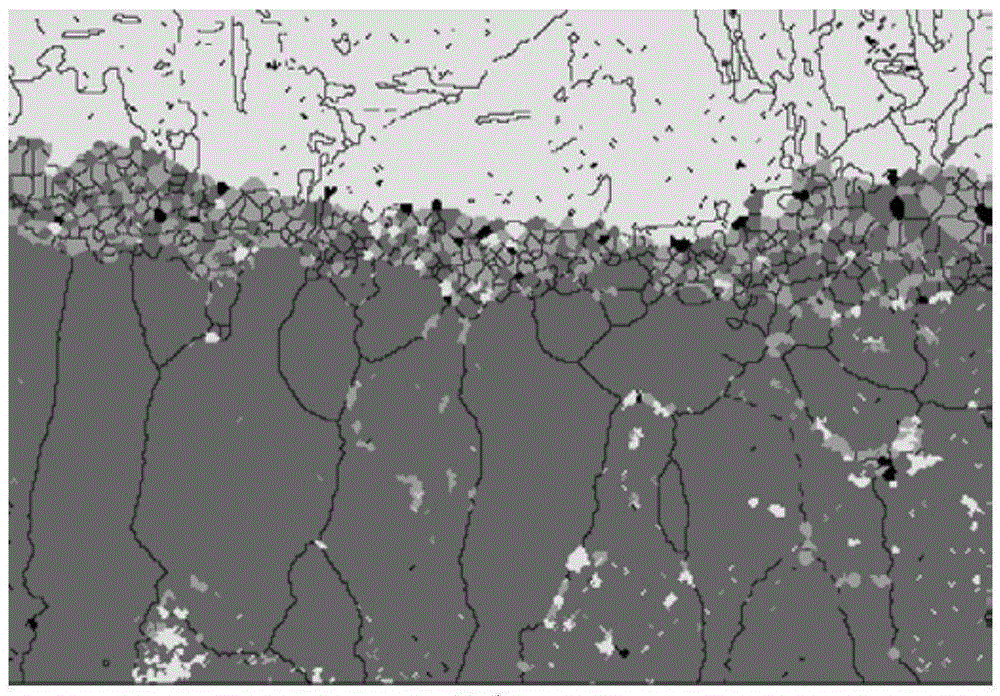

[0021] This example is to prepare a cross-sectional sample of iron oxide scale of Q345 hot-rolled plate, observe the iron oxide scale with a scanning electron microscope to obtain EBSD surface scanning data, and analyze the microstructure of the scanned area on the basis of phase composition analysis. The specific technical steps are:

[0022] 1. Preparation of oxide scale cross-section samples of hot-rolled plates

[0023] 1.1 Bonded sample

[0024] Generally speaking, the thickness of the hot-rolled iron oxide scale is only a few microns, and the surface of the oxide scale block sample can be bonded with another plate-shaped test block. The bonding can make there is no gap between the sample and the thin plate, increasing the test The sample thickness is also convenient for subsequent grinding and polishing samples. One method uses 502 glue for bonding, and the other method uses conductive tape for bonding.

[0025] 1.2 Cutting sample:

[0026] The cutting of the sample ...

Embodiment 2

[0055] In this example, samples were prepared for the oxide scale cross section of a 550CL hot-rolled plate, and the oxide scale was observed with a scanning electron microscope to obtain EBSD surface scanning data, and the microstructure analysis was performed on the scanned area on the basis of phase composition analysis.

[0056] The specific technical steps are:

[0057] Steps 1 and 2 use the same method as Embodiment 1, except that 502 glue is used when bonding the sample, and then the sample is subjected to step 1.6 coating treatment. For EBSD analysis, the coating of the sample should be very thin, and the thickness range is 2- 5nm, the coating material is made of carbon, which overcomes the charging phenomenon of the scanning electron microscope;

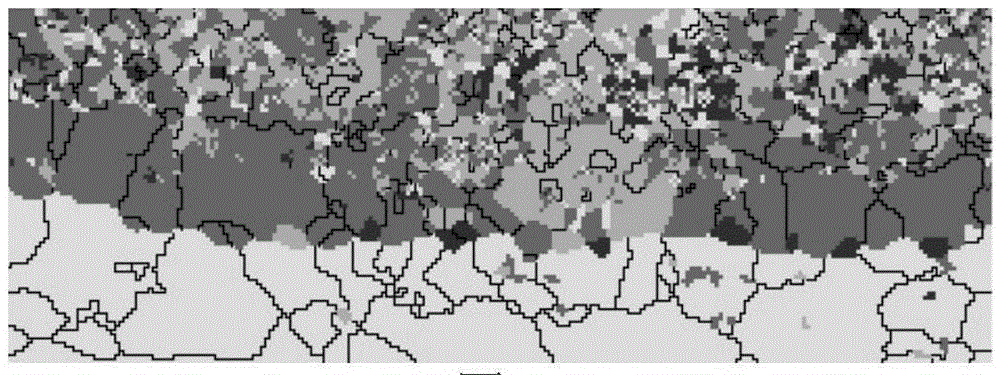

[0058] 3. EBSD surface scan data analysis

[0059] 3.1 Removal of noise and mislabeling

[0060] Using the Oxford Instruments (Channel5) data processing module, put this project into the phase analysis interface, use to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com