Improved conveyor belt take-up assembly and method

一种传送带、改进型的技术,应用在输送机物件、输送机、输送机控制装置等方向,能够解决传送带翘曲等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

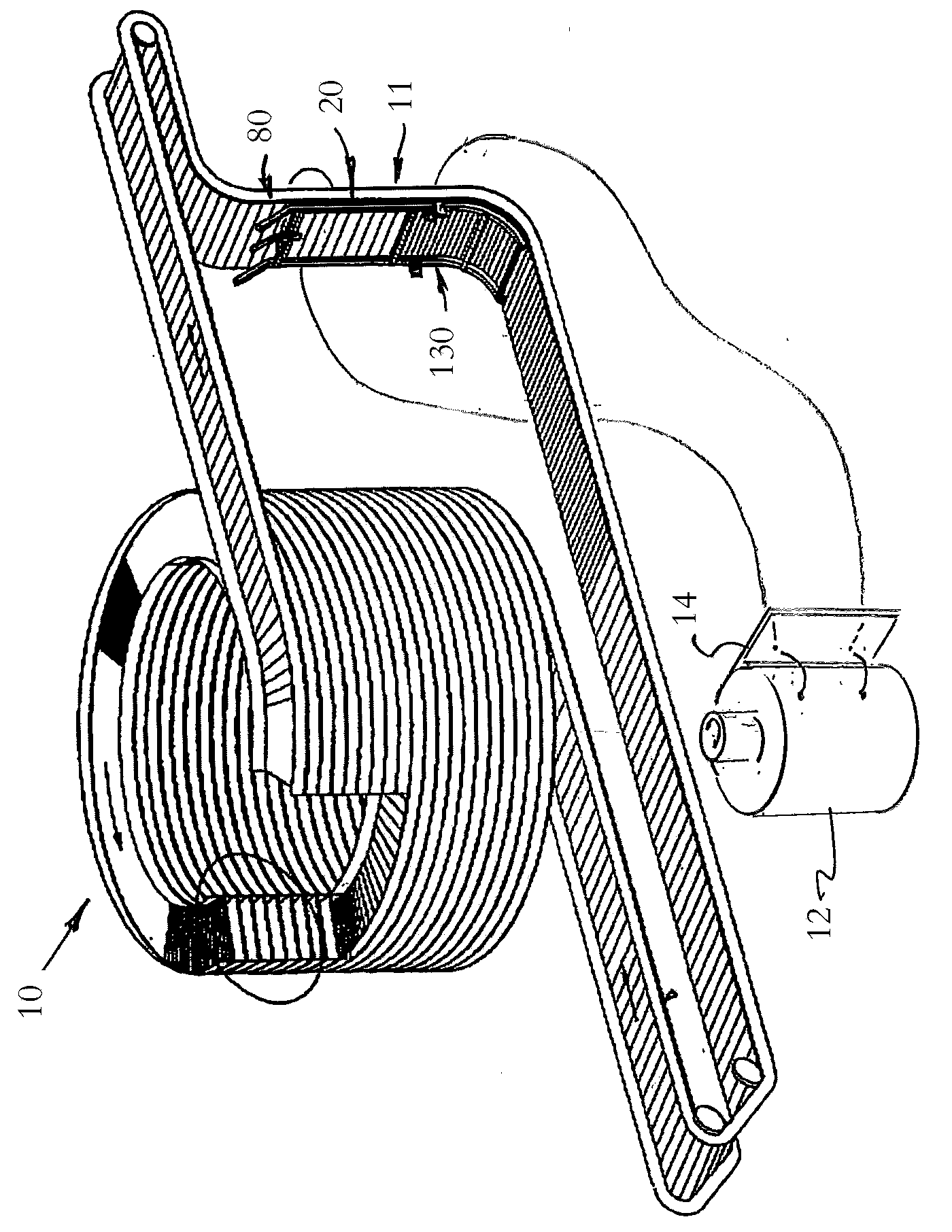

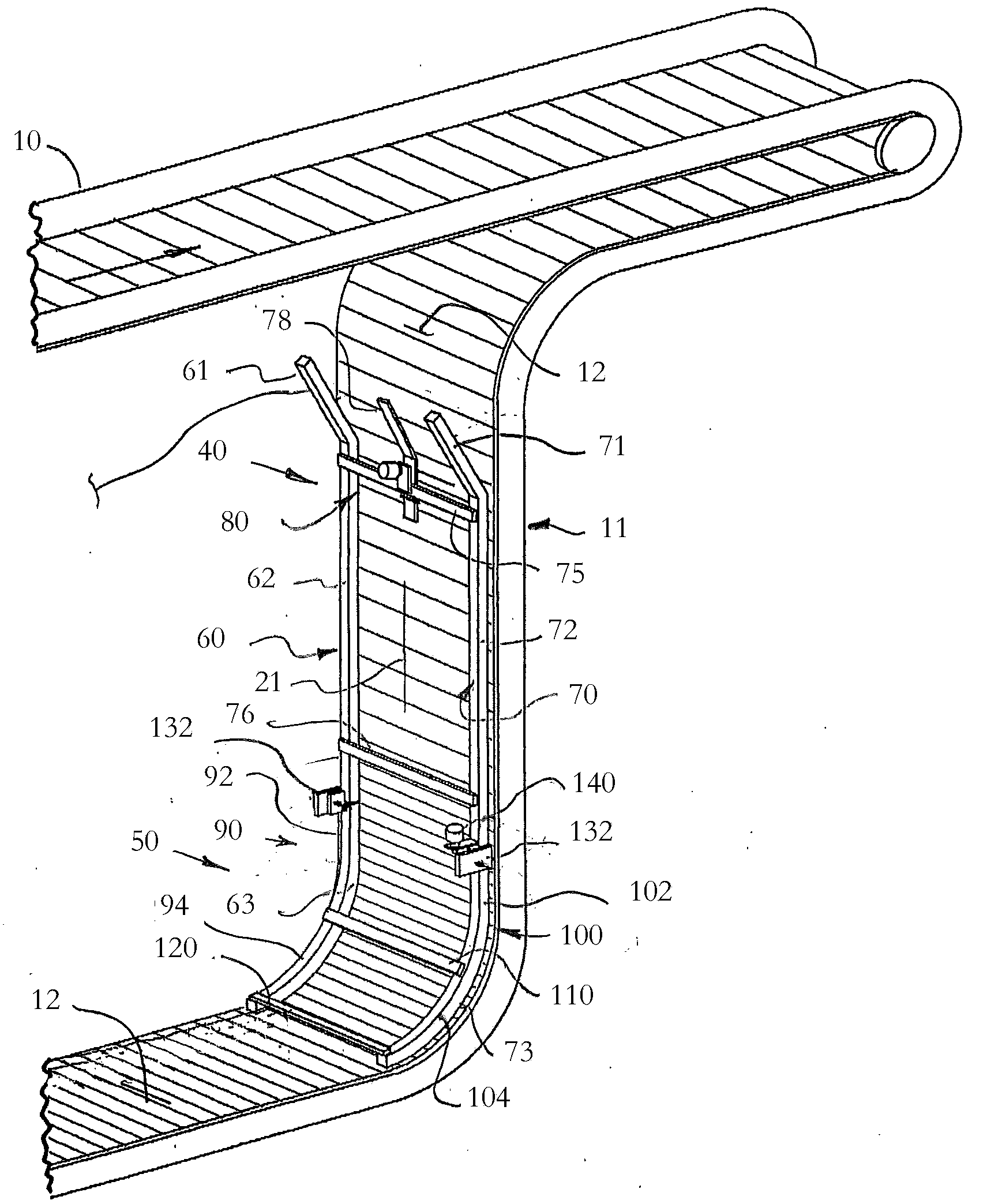

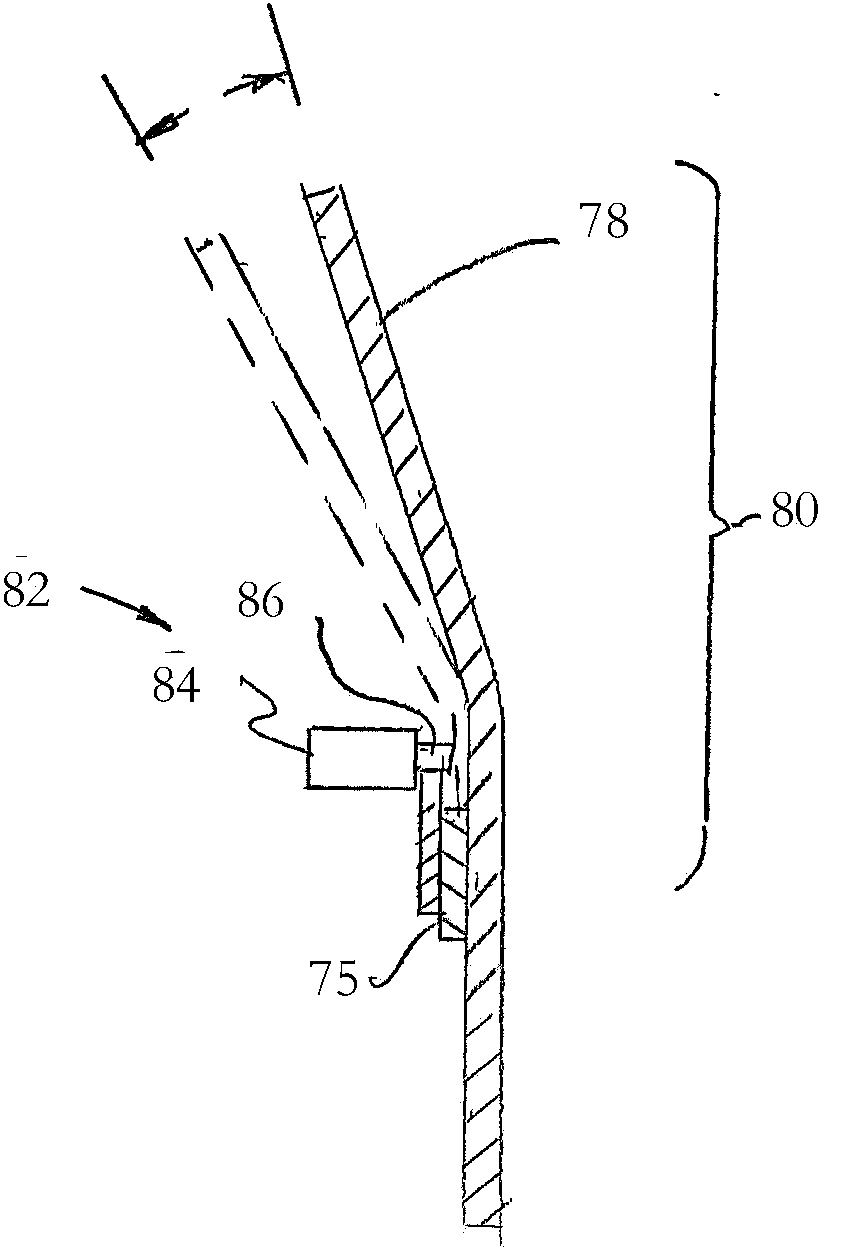

[0019] Referring to the drawings, there is shown an improved take-up assembly 20 for a spiral conveyor 10 with a swing arm assembly mounted on its lower end, and two obstacle sensing subsystems 80, 130. At least one, both subsystems automatically shut down the drive motor 12 for moving the conveyor belt 10 when an obstacle is detected upstream or downstream of the tensioning assembly 20 . These obstacle sensing subsystems 80 , 130 are located on opposite ends of the tensioning assembly 20 and are designed to allow the normal collapse and extension movement of the conveyor belt 10 within the tensioning assembly 20 . When excess tension or warping motion of the conveyor belt 10 occurs just downstream or upstream of the tensioning assembly 20, one of these obstacle sensing subsystem sensors 80, 130 is activated, thereby automatically deactivating the drive motor 12 of the conveyor belt And the movement of the conveyor belt 10 is stopped.

[0020] Such as figure 1 As shown in , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com