Processing technique for repeatedly stretched speaker frame

A loudspeaker pot frame and processing technology, applied in the direction of sensors, electrical components, etc., can solve the problems of high difficulty, high defective rate, unrealizable process methods, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

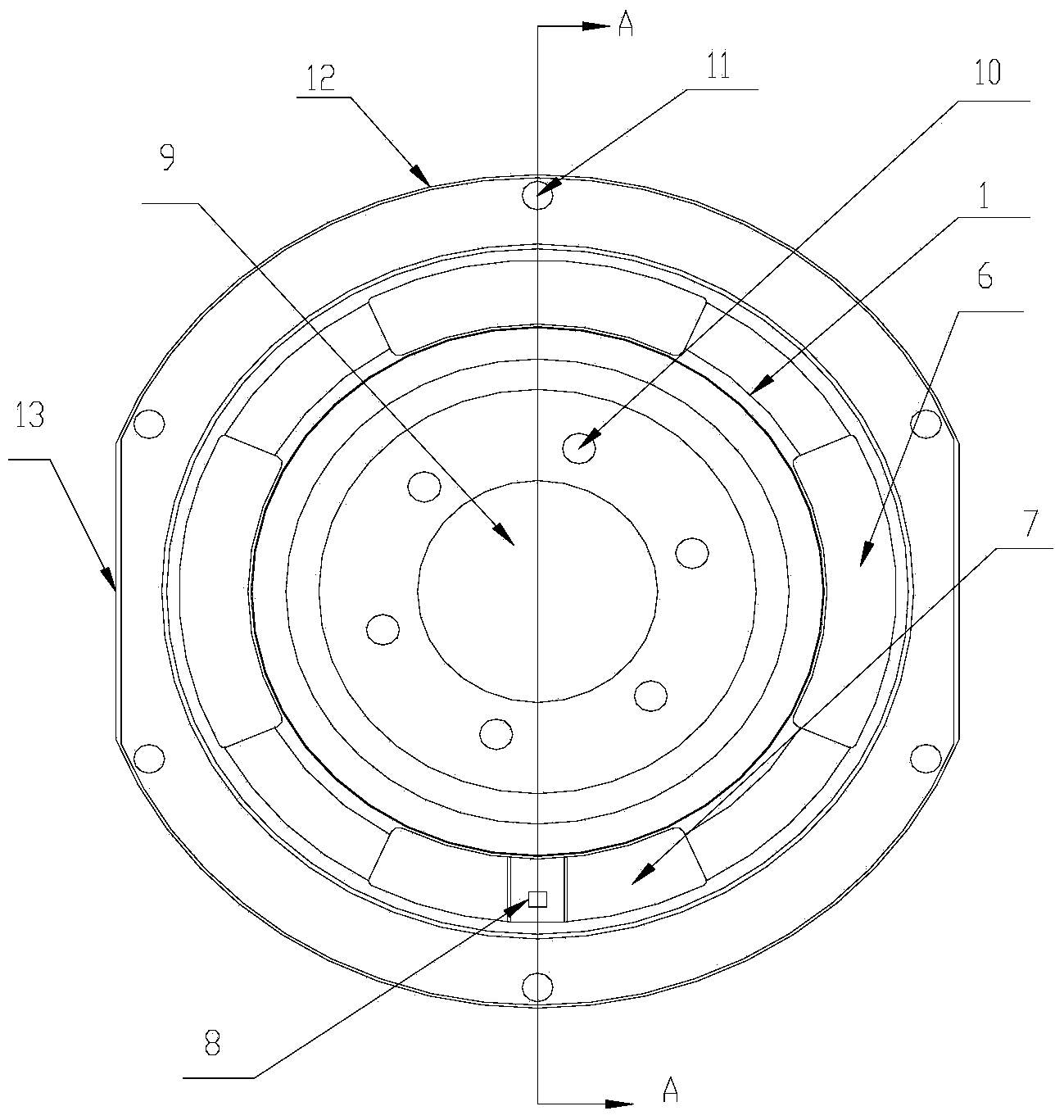

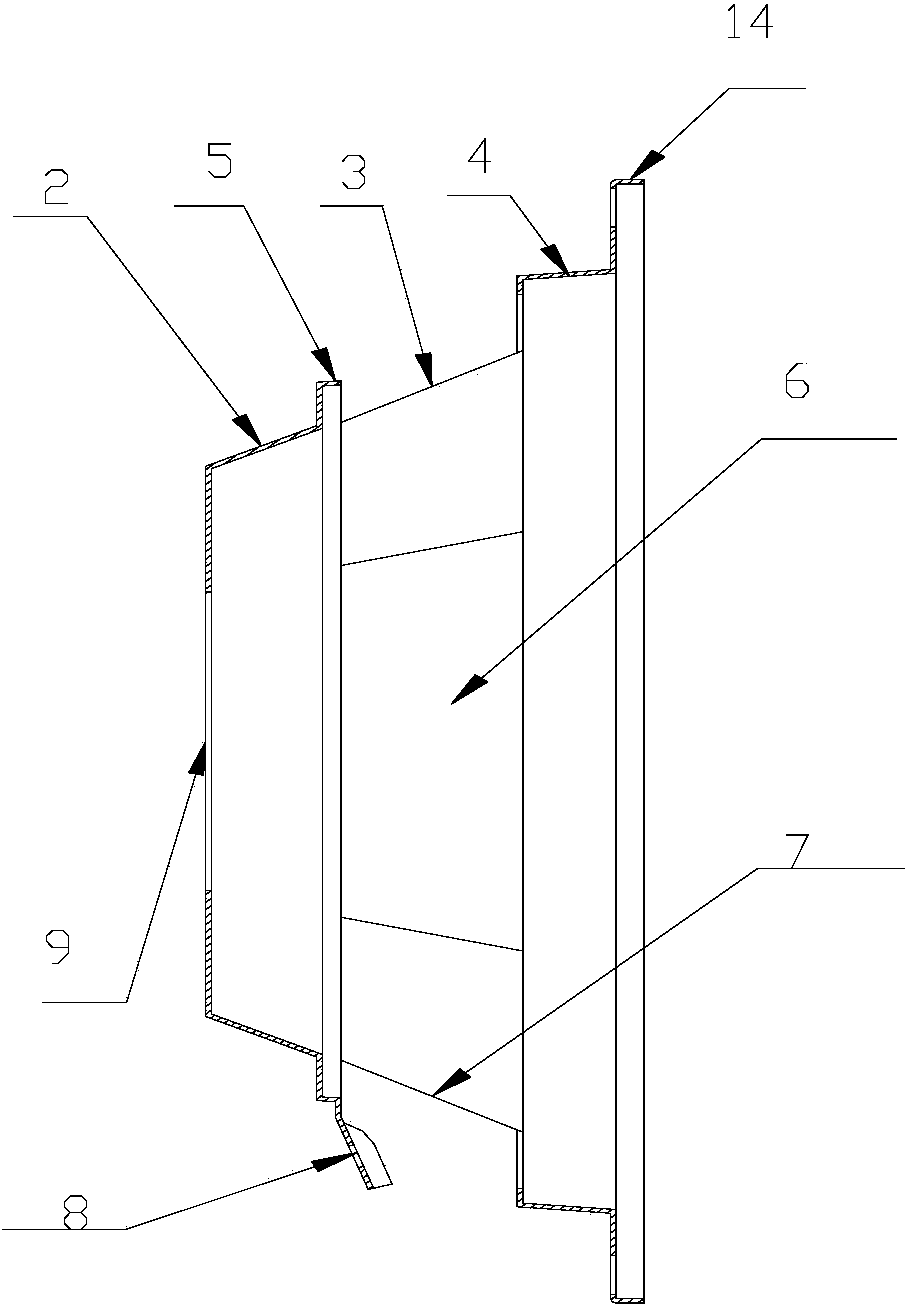

[0023] Such as figure 1 and figure 2 Shown, a kind of processing technology of the loudspeaker pot frame that stretches for many times, comprises the following steps:

[0024] Step 1: cutting, cut out a strip of coil material that is 209 millimeters wide on the cold-rolled carbon steel sheet that thickness is 0.6 millimeters by shearing machine;

[0025] Step 2: Blanking, punching out a square raw material with a side length of 209 mm on the coiled material through a blanking continuous die;

[0026] Step 3: punching grooves, punching a groove 1 on the square raw material through a punching groove continuous die, the inner diameter of the groove 1 is 94.26 mm, and the outer diameter of the groove 1 is 107 mm, The center of the groove 1 coincides with the center of the square material;

[0027] Step 4: Stretching for the first time, punching out the first step 2 from the square raw material punched with the groove 1 through the continuous die for the first stretching, the h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap