CNC Multifunctional Metal Tensioner

A tensioning machine and multi-functional technology, applied in the field of cold drawing equipment, can solve the problems of difficult product quality control, low production efficiency, restricted development, etc., and achieve the effects of reducing work intensity, ensuring consistency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] 1. Main structure

[0057] Such as figure 1 As shown: the CNC multifunctional metal tensioning machine includes four parts: the left working platform I, the middle working platform II, the right working platform III and the control system IV. The left working platform I and the right working platform Ⅲ is symmetrically arranged on the left and right sides of the middle working platform Ⅱ.

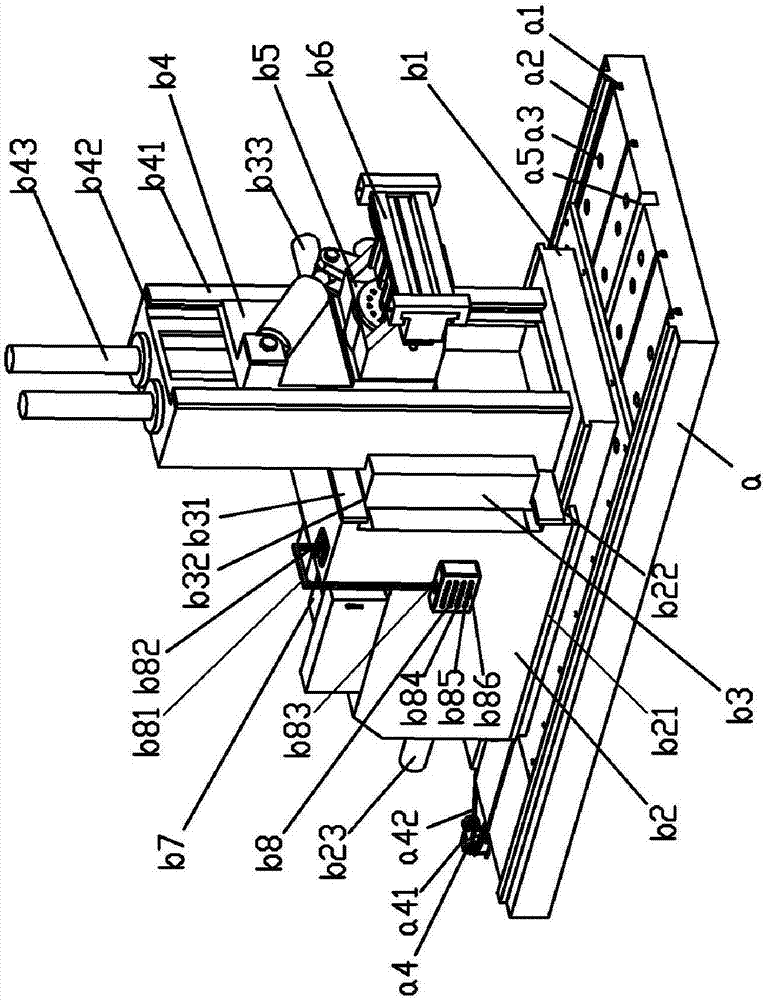

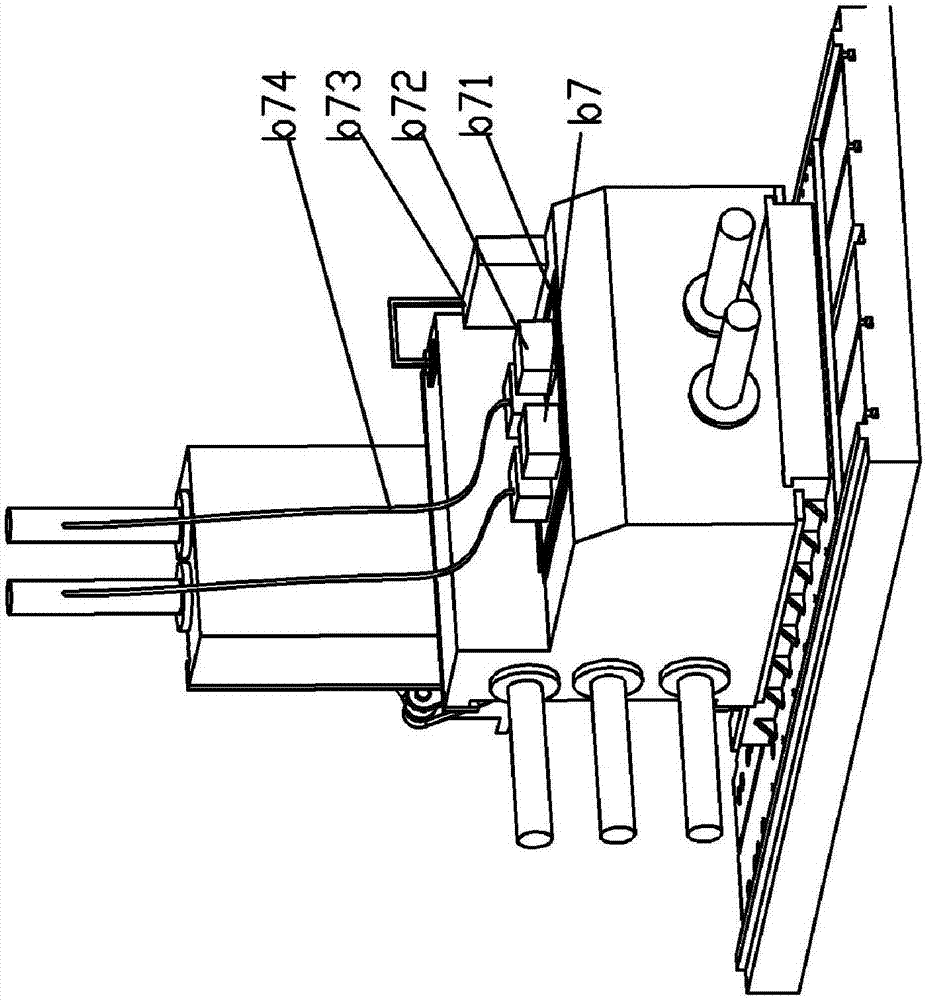

[0058] The multi-functional metal tensioning machine is divided into three working platforms: left, middle and right. There is a stretching unit b on each of the left and right working platforms a. Driven by the hydraulic system b7, the unit can be used for X, Y, Z three-direction displacement movement, at the same time, the clamp body b6 equipped with hydraulic clamping device can rotate under the push of the rotary cylinder b53, and cooperate with the three-direction movement of the unit to realize the four-axis controllable movement of the unilateral clamp. The left and right wo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap