Loading tracking apparatus

A tracking device and filling technology, which is applied in the field of food and pharmaceutical packaging machinery, can solve the problems of large transmission vibration and unstable operation, and achieve the effects of fast and stable tracking, reduced filling risk, stable motion path and no vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

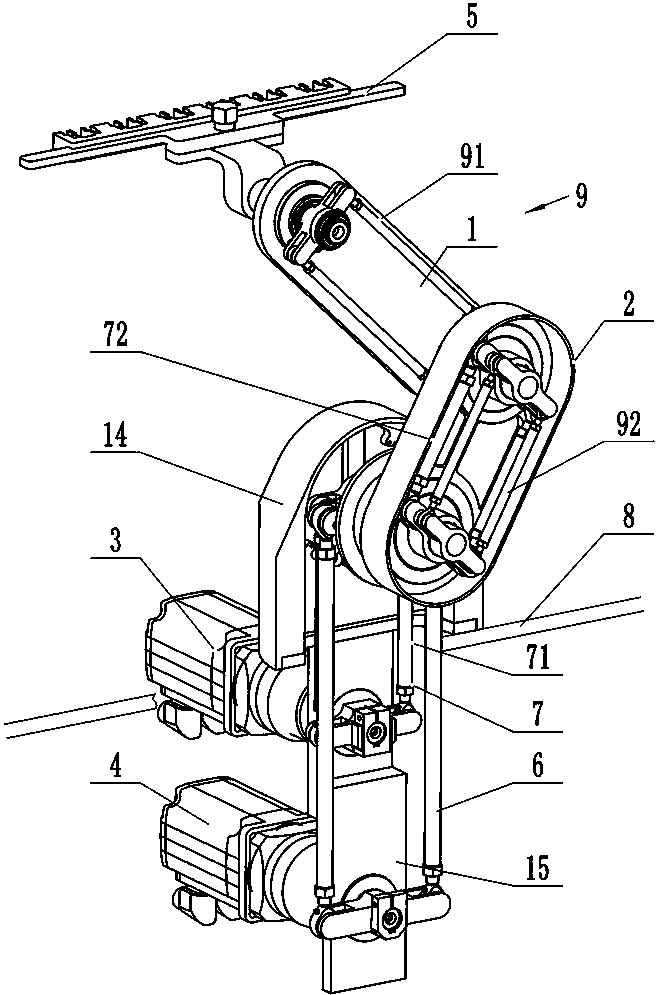

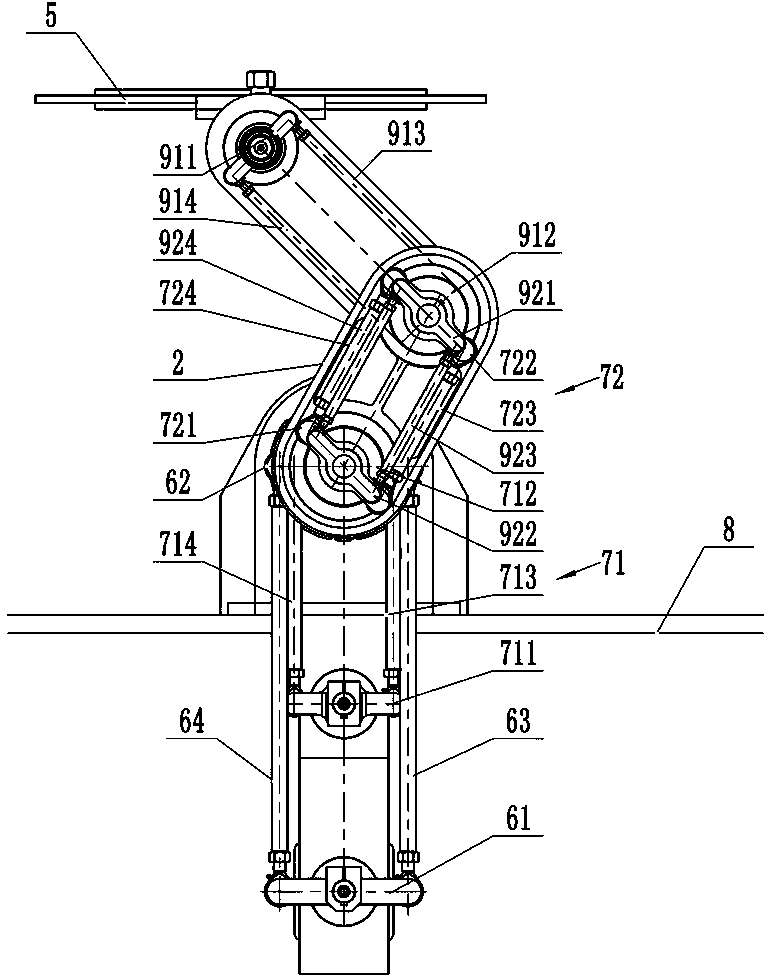

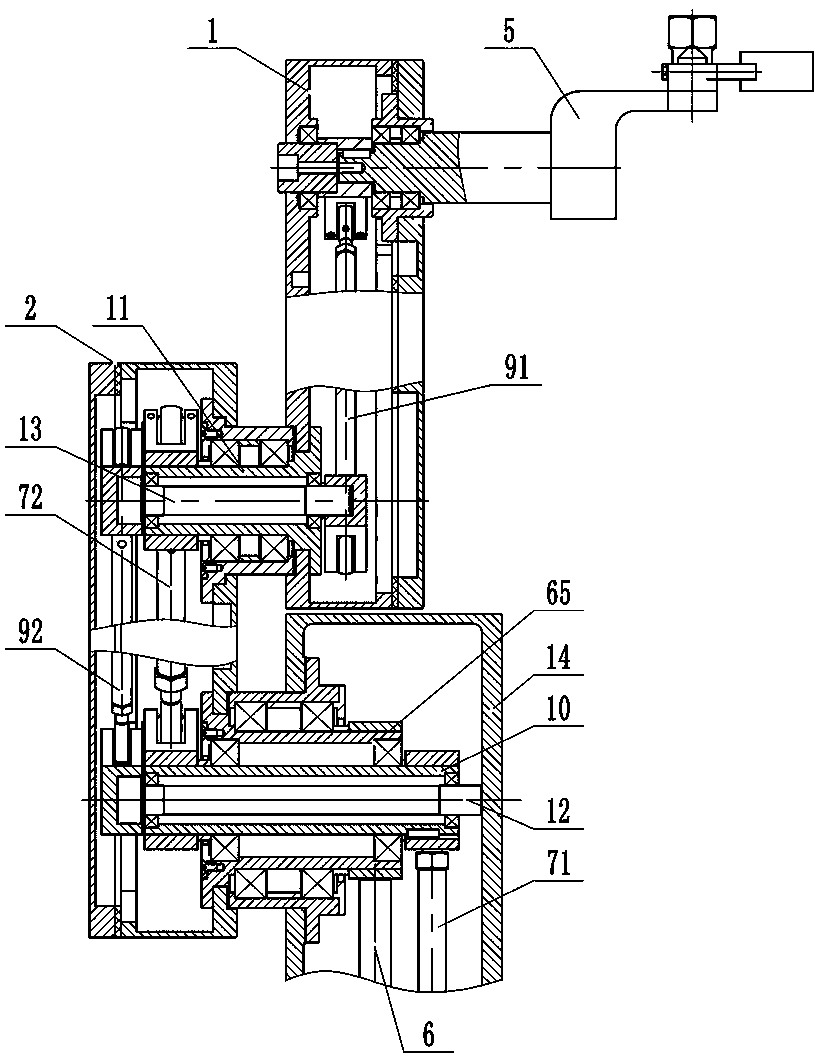

[0021] Such as Figure 1 to Figure 3 As shown, the filling tracking device of this embodiment includes a filling injection needle frame 5, an upper swing arm 1, a lower swing arm 2, an upper swing arm driver 3, a lower swing arm driver 4 and a swing arm mounting support 14. The spray needle rack 5 is set on the working end of the upper swing arm 1 and is hinged with the upper swing arm 1, the upper swing arm 1 is hinged with the lower swing arm 2, the swing arm mounting support 14 is hinged with the lower swing arm 2, and the lower swing arm driver 4 passes through The lower swing arm parallelogram linkage mechanism 6 drives the lower swing arm 2 to swing, and the upper swing arm driver 3 drives the upper swing arm 1 to swing through the upper swing arm parallelogram linkage mechanism 7. Both the upper and lower swing arms of the present invention pass through the parallelogram linkage mechanism Swing, the parallelogram linkage mechanism 6 of the lower swing arm and the parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com