Automatic thermal sleeve device and its control method

An automatic and packaged technology, applied in the direction of manufacturing tools, transportation and packaging, conveyor objects, etc., can solve the problems of difficult rotation of hole workpieces, many unsafe factors, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

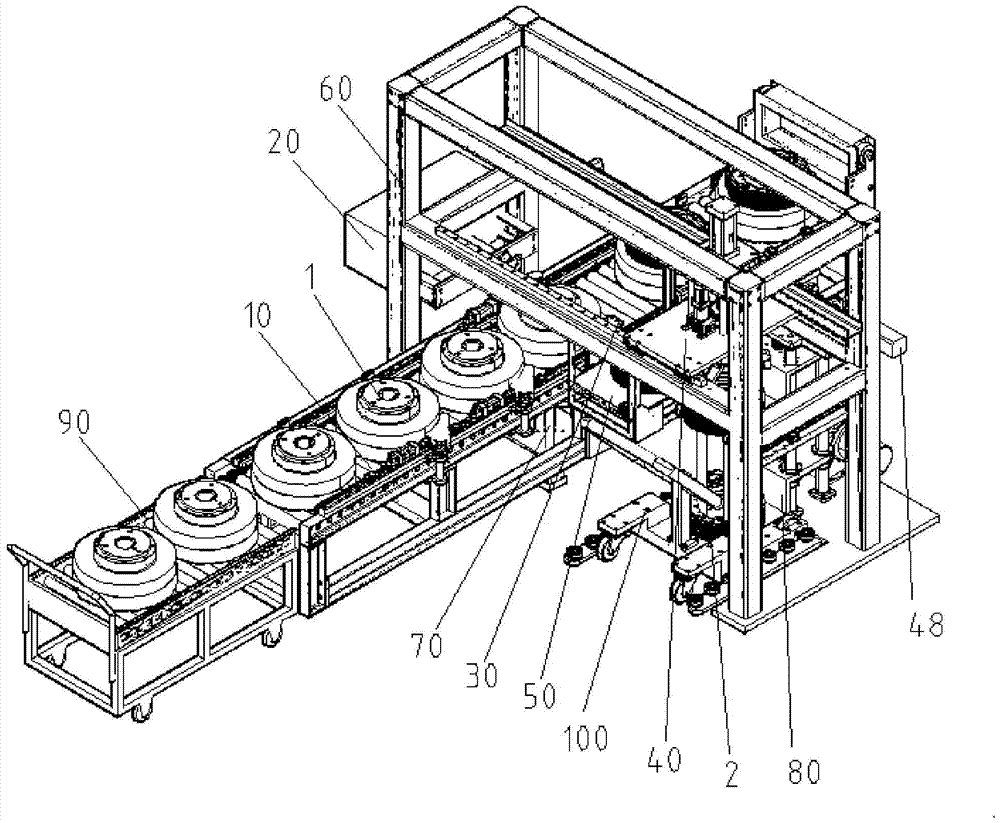

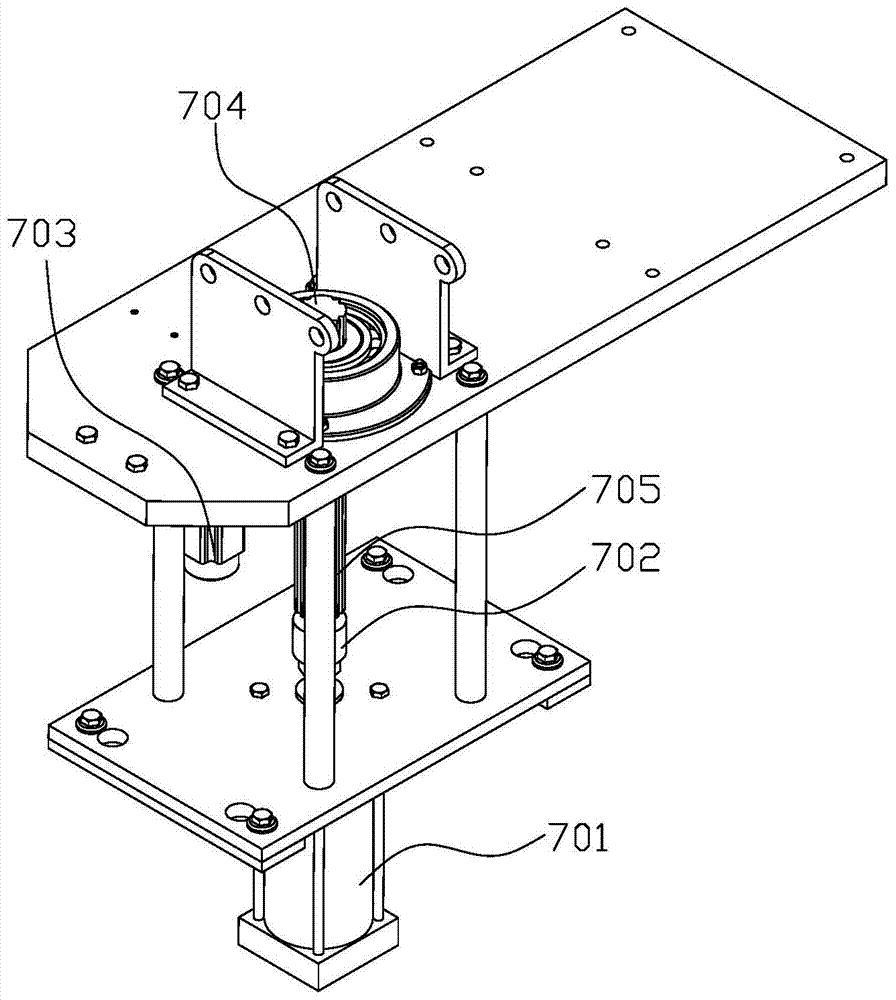

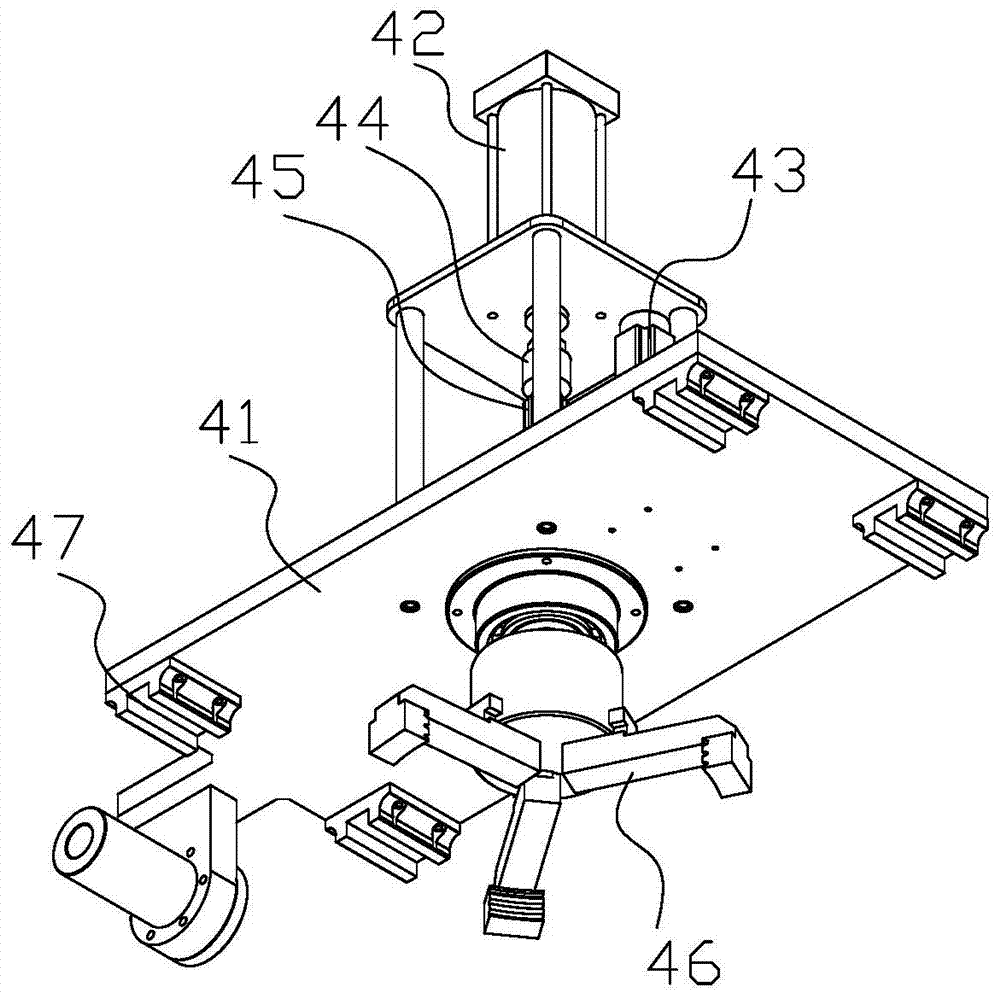

[0035] Such as figure 1 As shown, an automatic shrink-fitting device includes an assembly line 10, a first hole-pairing mechanism 20, a second hole-pairing mechanism 30, a grasping mechanism 40, a heating mechanism 50, and a mounting horizontal frame 60 across the assembly line 10. Said assembly line 10 is provided with a suiting station, said suiting station is provided with a positioning and rotating mechanism 70, said grasping mechanism 40 is movably arranged on said installation horizontal frame 60, and said first pair of hole mechanism 20 It is arranged on the side of the positioning and rotating mechanism 70, the positioning and rotating mechanism 70, the heating mechanism 50, and the second pair of hole mechanism 30 are all arranged below the grasping mechanism 40, and the first pair of hole mechanism 20 has The first detection point, the second hole m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com