Lifting force measuring device and equipment and method for measuring actual locking rail temperature of jointless track

A seamless line rail and measuring device technology, applied in railway auxiliary equipment, railway vehicle shape measuring devices, transportation and packaging, etc., can solve problems such as complex operation, high application environment requirements, and calculation result errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

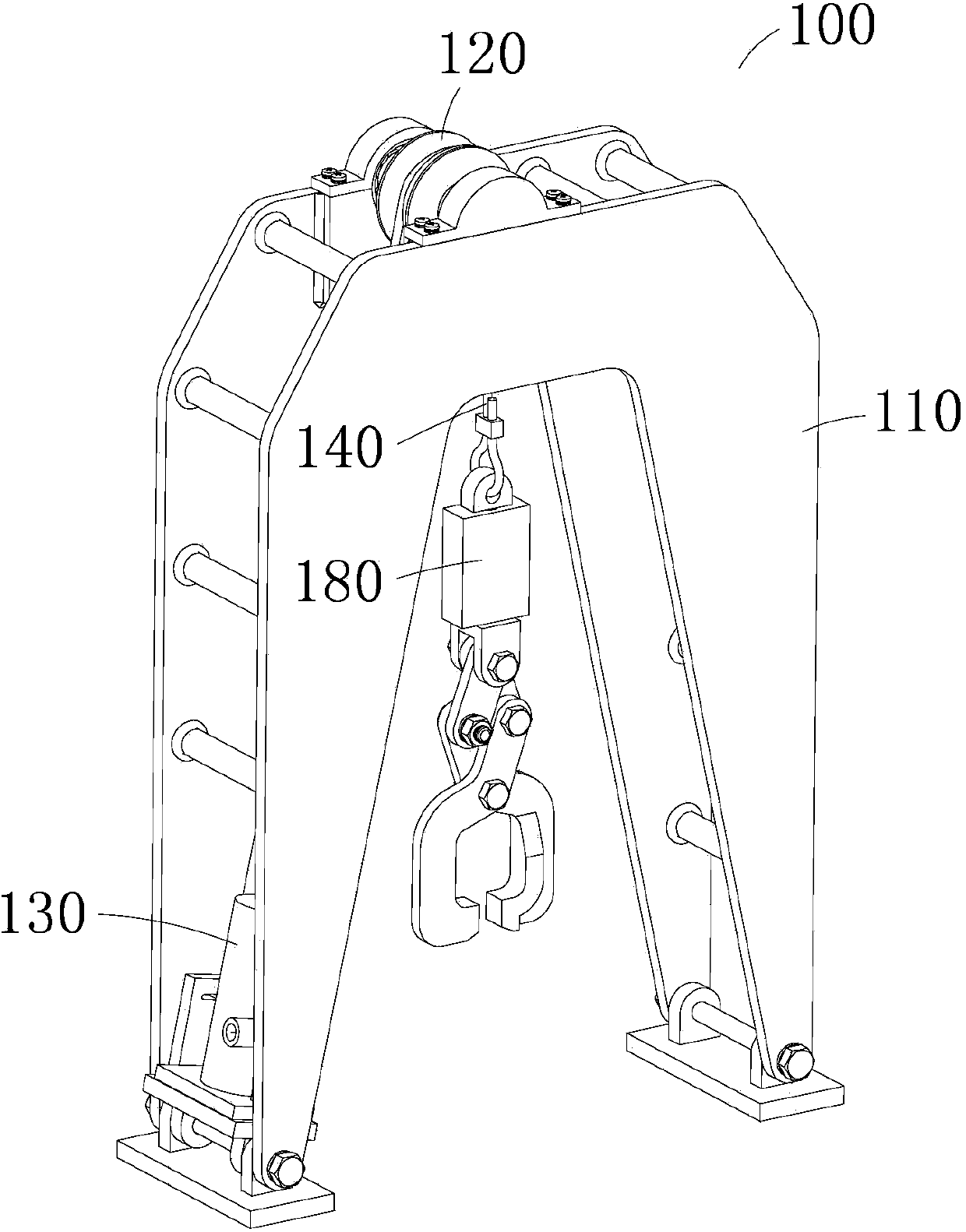

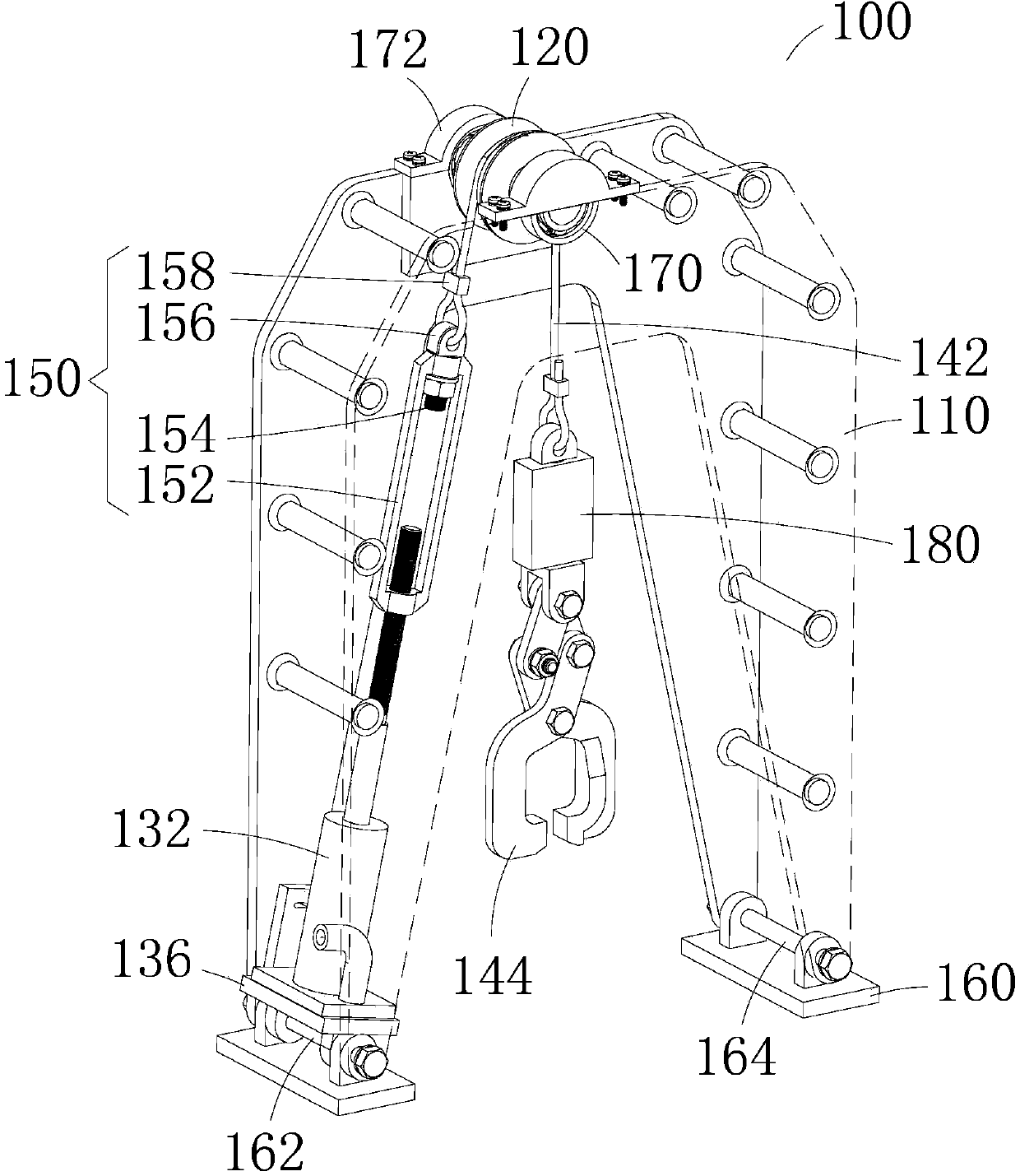

[0111] see figure 2 As shown, a lifting force measurement device 100 of the present invention includes a bracket 110 , a transverse shaft 120 , a pullback mechanism 130 , a flexible lifting mechanism 140 and a tension sensor 180 . The horizontal shaft 120 is disposed on the upper part of the bracket 110 .

[0112] Please combine image 3 As shown, the two ends of the pullback mechanism 130 are respectively a fixed end and a movable end. The fixed end is axially connected to the support 110 , and the movable end is connected to one end of the flexible lifting mechanism 140 . The flexible lifting mechanism 140 is wound around the transverse axis 120, and the other end of the flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com