Wiring system and method based on ink-jet printing and selective laser melting

A technology of laser melting and inkjet printing, applied in printing, typewriters, etc., can solve problems such as cumbersome procedures, achieve efficient wiring methods, high-precision wiring methods, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

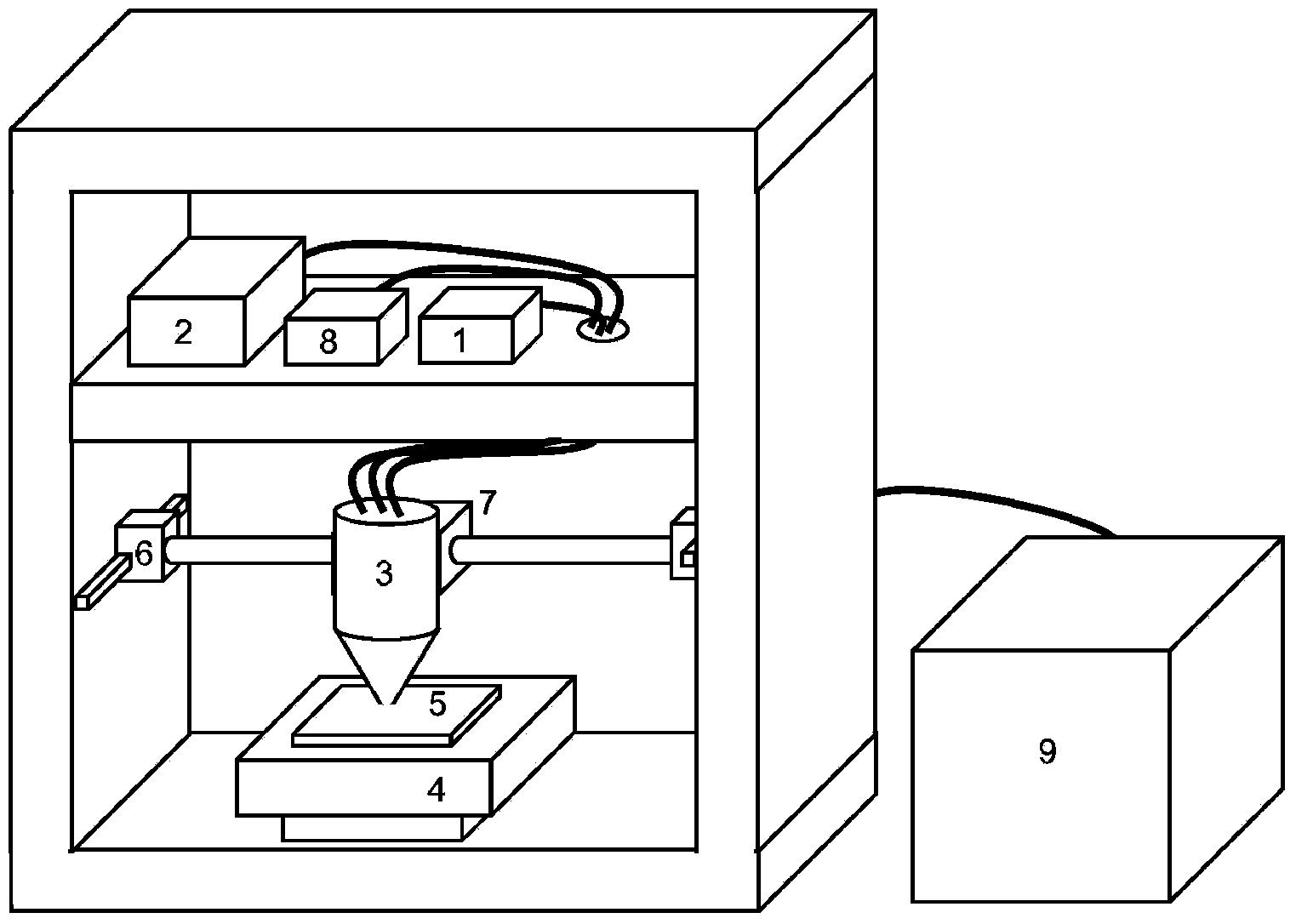

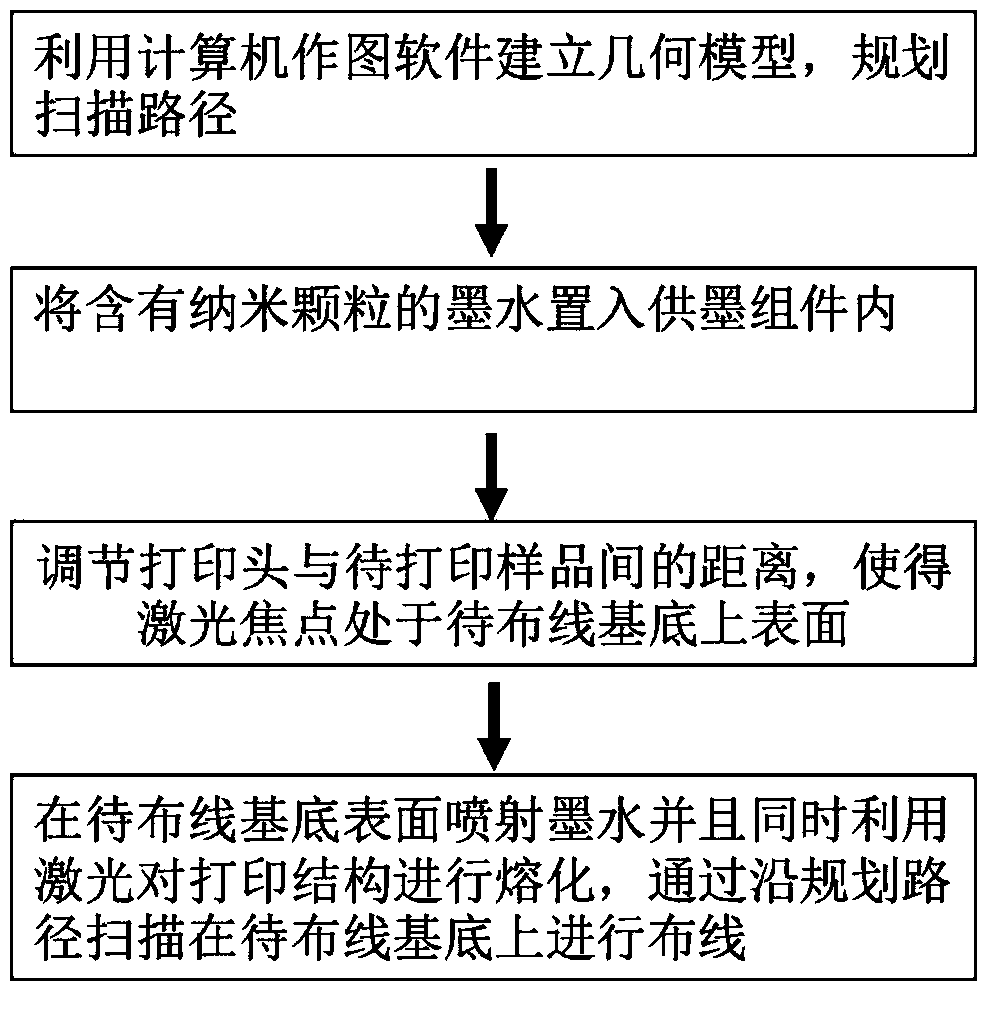

[0052] Combine the following figure 1 and figure 2 , the present invention will be described in detail by taking the silver metal wiring on the glass substrate by using the wiring method based on inkjet printing and selective laser melting as an example.

[0053] First, use computer graphics software to establish a geometric model and plan the scanning path;

[0054] Ink containing silver nanoparticles with a particle size of 1 to 10 nm is placed in the ink supply assembly 1;

[0055] Move the lifting angle displacement table 4 through computer control, adjust the distance between the printing head 3 and the glass substrate 5 to be 0.1mm to 1mm, so that the laser focus is on the upper surface of the glass substrate;

[0056] Ink is sprayed on the upper surface of the glass substrate 5 to be prepared and at the same time, the structure is irradiated and melted with an 808nm focused laser with a power of 20W to 60W, and the laser focal spot size is 0.1mm to 1mm;

[0057] The...

Embodiment 2

[0059] refer to figure 1 and figure 2 , the present invention will be described in detail by taking copper metal wiring on a hemispherical crown-shaped plastic substrate by using a wiring method based on inkjet printing and selective laser melting as an example.

[0060] First, use computer graphics software to establish a geometric model and plan the scanning path;

[0061] Put the ink containing copper nanoparticles with a particle size of 1 to 10 nm into the ink supply assembly 1;

[0062] Controlled by a computer to move the lifting angle displacement table 4, adjust the distance between the print head 3 and the highest point 5 of the hemispherical crown-shaped plastic base to be 0.1mm-1mm, so that the laser focus is on the upper surface of the highest point of the hemispherical crown-shaped plastic base;

[0063] Spray ink on the upper surface of the hemispherical crown-shaped plastic substrate 5 and at the same time use an 808nm focused laser with a power of 20W to 60...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap