Bearing assembly with safety bush and insertion method

A technology of bearing components and bushings, which is applied in the direction of bearing assembly, bearing components, and rotating bearings, etc., and can solve the problems of increasing assembly time with non-special tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

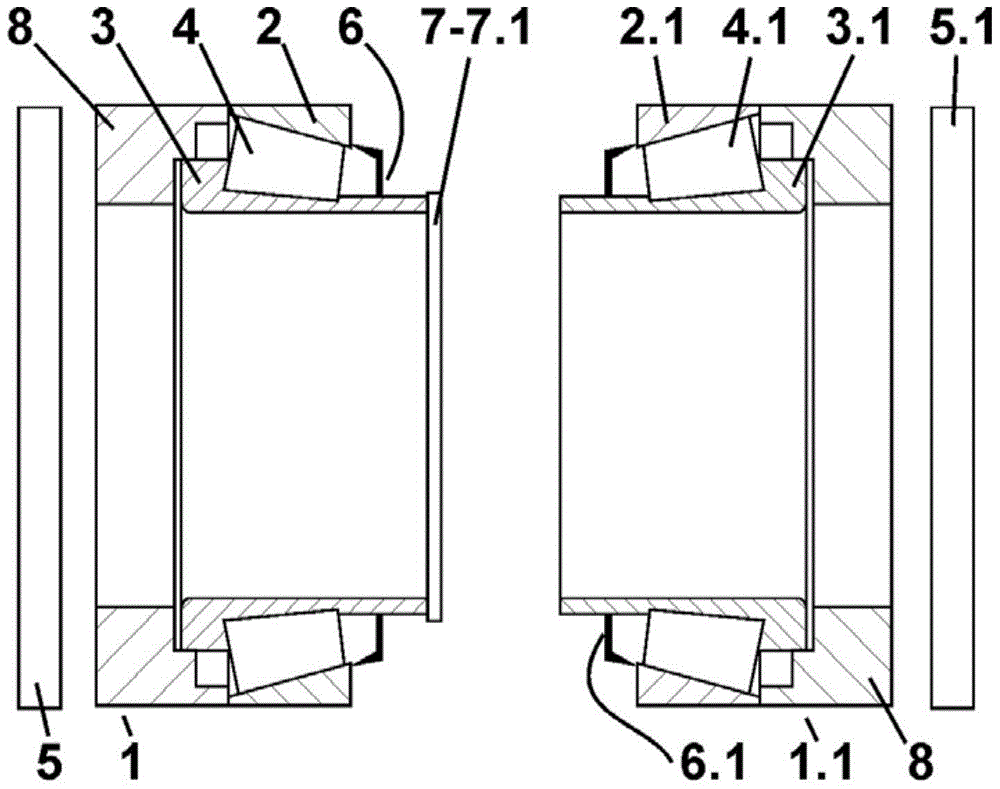

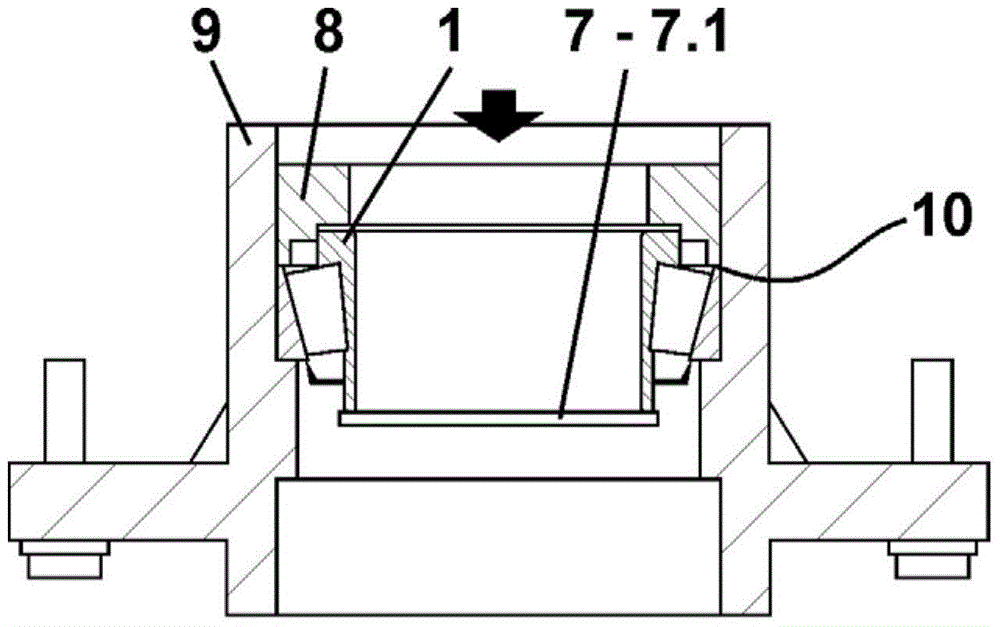

[0029] The bearing assembly with safety bushing comprises two pre-assembled units 1, 1.1 that can be placed on the hub 9 of a commercial vehicle. Each unit comprises: an outer ring 2, 2.1 and an inner ring 3, 3.1, a plurality of tapered rollers 4, 4.1 in a cage; and an identification box 6, 6.1 which axially fixes the outer ring 2, 2.1; and Safety bushing 8, safety bushing 8 is a ring similar in size to the pre-assembled unit 1, 1.1, fitted between the outer ring 2, 2.1 and the inner ring 3, 3.1, and constitutes a compact assembly which can be used as a The pre-assembled unit is mounted on the hub 9 and the tool for mounting the holder 5 , 5 . 1 in the cavity between the pre-assembled unit and the hub 9 .

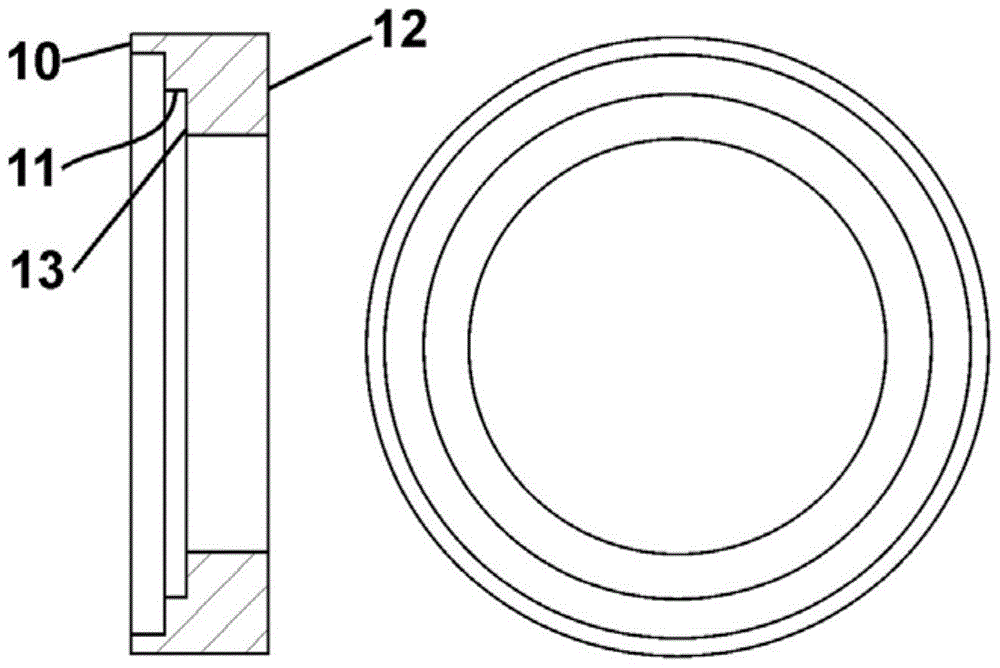

[0030] Safety bushings consist of four distinct surfaces:

[0031] The outer ring 2, 2.1 and the thrust surface 10 of the cage 5, 5.1, the thrust surface 10 is axially connected with the outer ring 2, 2.1. This surface moves the pre-assembled unit 1, 1.1 and can also be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com