Testing method and equipment for water erosion resistance of ceramic mud

A technology of ceramic mud and detection method, which is applied in the direction of measuring device, material weighing, analyzing material, etc., can solve problems such as mud falling off, and achieve the effect of simple structure, simple operation and stable test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

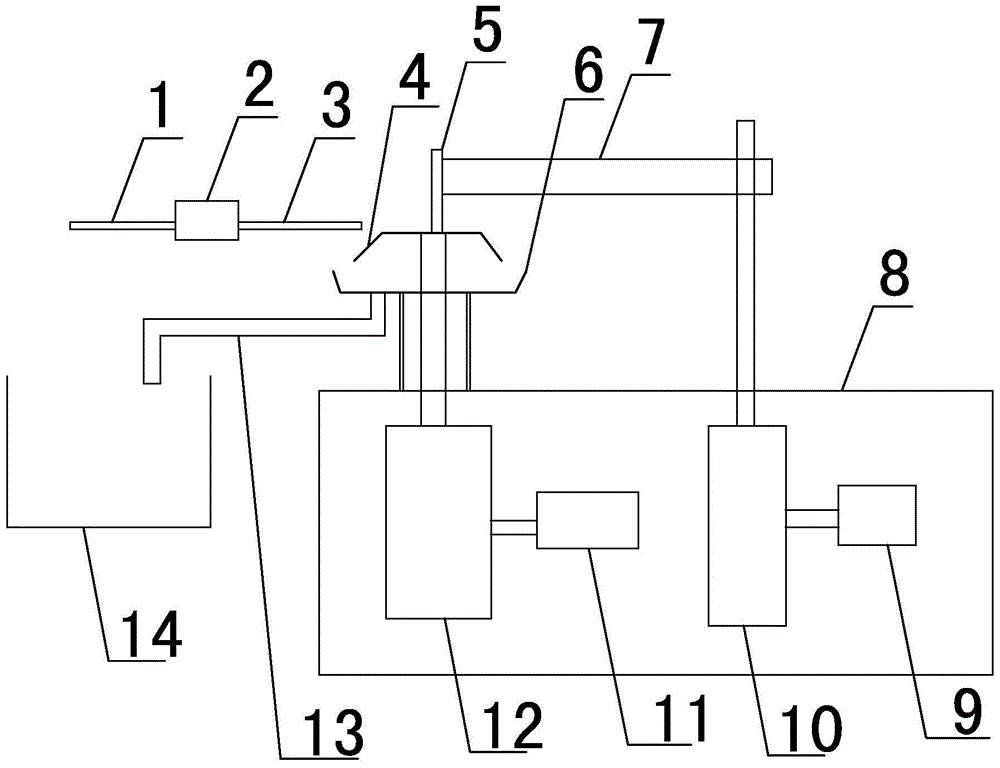

[0039] The method for detecting water erosion resistance of the ceramic mud comprises the following steps:

[0040] (1) Knead or knead the ceramic mud material, and prepare 300 g of cylindrical regular samples after fully mixing;

[0041] (2) The sample is fixed on the loading tray 4 with a sharp fixed shaft 5;

[0042] (3) Adjust the position of the elastic sheet 7 (the coefficient of friction of the elastic sheet is 0.6) so that the contact position with the sample is as low as possible, that is, the upper edge of the elastic sheet 7 is lower than the tip of the fixed shaft 5, and the torque is controlled by adjusting the torque. The device 9 adjusts the value of the torque meter 10 to 1.5N;

[0043] (4) The water flow inlet 1 is connected with the tap water pipe, and the water flow controller 2 is adjusted to a water flow rate of 40g / min. At the same time, the water outlet of the water flow outlet 3 is aligned with the contact position between the elastic sheet 7 and the m...

Embodiment 2

[0049] The detection method of described ceramic mud material anti-water erosion ability, other is identical with embodiment 1, and difference is:

[0050] Adjust the value of torque meter 10 to 4.5N;

[0051] The water flow rate is 80g / min;

[0052] The running time of the motor 12 is 10 minutes;

[0053] The rotating speed of motor 12 is 5r / s;

[0054]The coefficient of friction of the elastic sheet 7 is 0.8;

[0055] Such as figure 1 As shown, the testing equipment for the water erosion resistance of the ceramic mud is the same as that in Example 1.

[0056] The elastic sheet has a width of 3 cm.

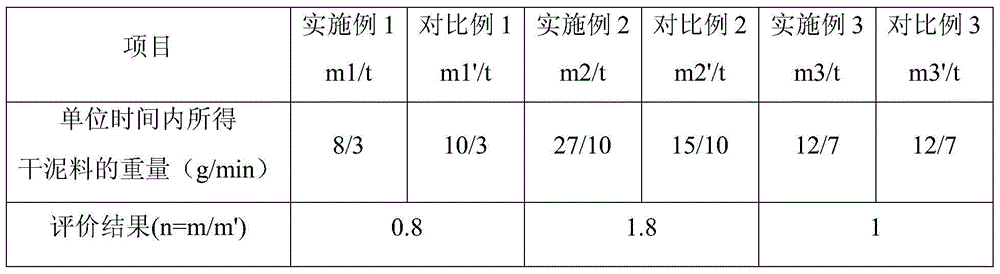

[0057] Finally, the mass m2 of the dry material was weighed to be 27g.

Embodiment 3

[0059] The detection method of described ceramic mud material anti-water erosion ability, other is identical with embodiment 1, and difference is:

[0060] Adjust the value of torque meter 10 to 3.0N;

[0061] The water flow rate is 60g / min;

[0062] The running time of the motor 12 is 7 minutes;

[0063] The rotating speed of motor 12 is 3r / s;

[0064] The coefficient of friction of the elastic sheet 7 is 0.7;

[0065] Such as figure 1 As shown, the testing equipment for the water erosion resistance of the ceramic mud is the same as that in Example 1.

[0066] The width of the elastic sheet 7 is 3 cm.

[0067] Finally, the mass m3 of the dry material was weighed to be 12g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com